Sintered neodymium iron boron magnet surface functional film and preparation method thereof

A functional film, NdFeB technology, applied in permanent magnet manufacturing, inductor/transformer/magnet manufacturing, coating, etc., can solve the problems of poor corrosion resistance, improve high temperature resistance and oxidation resistance, good hardness and resistance The effect of corrosion protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

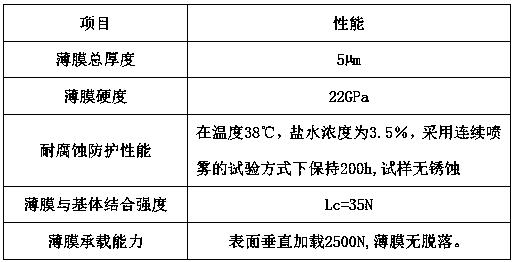

[0027] Fill the vacuum chamber with argon gas to a pressure of 0.5Pa, and the radio frequency power is 115W, and deposit an aluminum oxide film layer on the magnet body by radio frequency sputtering; finally, discharge the gas in the vacuum chamber, according to the argon gas flow rate of 30 sccm and nitrogen gas flow rate of 2 sccm Fill the vacuum chamber with argon and nitrogen until the pressure in the vacuum chamber is 0.35Pa, adjust the power of the titanium target to 115W, deposit a titanium nitride film on the aluminum oxide film of the magnet body, turn off the power supply of the titanium target after completion, and the aluminum oxide and The thickness ratio of titanium nitride is 3:22. At this time, one cycle of deposition is completed, and four cycles are deposited according to the above steps. After testing, the performance of the composite film layer obtained under this condition is as follows:

[0028]

Embodiment 2

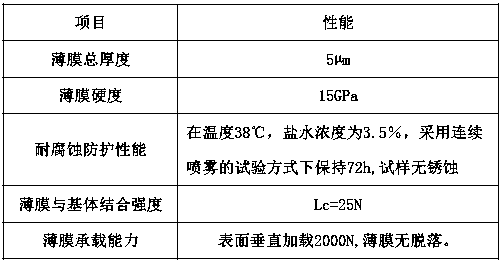

[0030] Fill the vacuum chamber with argon gas to a pressure of 0.5Pa, and the radio frequency power is 115W, and deposit an aluminum oxide film layer on the magnet body by radio frequency sputtering; finally, the gas in the vacuum chamber is exhausted, and the flow rate of the argon gas is 30 sccm and the nitrogen gas flow rate is 2 sccm. Fill the vacuum chamber with argon and nitrogen until the pressure in the vacuum chamber is 0.35Pa, adjust the power of the titanium target to 115W, deposit a titanium nitride film on the aluminum oxide film of the magnet body, turn off the power supply of the titanium target after completion, and the aluminum oxide and The thickness ratio of titanium nitride is 3:22. At this time, one cycle of deposition is completed, and 20 cycles are deposited according to the above steps. After testing, the performance of the composite film layer obtained under this condition is as follows:

[0031]

[0032] In an optional embodiment, the following ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com