Rare earth element erbium-modified cast hypoeutectic Al-Mg2Si alloy and preparation method thereof

A rare earth element and hypoeutectic technology, which is applied in the field of aluminum alloys, can solve problems such as hypoeutectic Al-Mg2Si alloys that have not yet been seen, and achieve the effects of low price, abundant resources, and improved plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

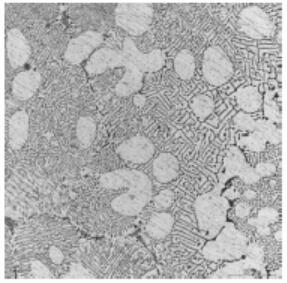

[0032] Al-8Mg 2 Add 0.20% Er to the Si alloy. According to the mass percentages of 91.80%Al, 5.06%Mg, 2.94%Si and 0.20%Er, weigh 1167.04g of aluminum ingot with a purity of 99.96%, 215.06g of Al-40Mg master alloy block, 249.90g of Al-Si master alloy block and 68.00g of Al -Er intermediate alloy block, as a raw material for making alloy ingots, the total mass of ingredients is 1700g. After the various prepared raw materials have been cleaned and dried, first put 1167.04g of aluminum ingots and 249.90g of Al-Si intermediate alloy blocks into a graphite crucible resistance furnace, heat them, and cool down to 700°C after they are completely melted at 720°C. Add the g Al-Mg intermediate alloy block into the melt until it melts, and let it stand for 5 minutes. Press 0.2% hexachloroethane into the melt with a graphite bell jar preheated at 300°C, stir at 740°C to remove scum on the surface of the melt. 68.00 g of Al-Er master alloy ingots were added to the melt at 780°C. After m...

Embodiment 2

[0035] Al-8Mg 2 Add 0.10% Er to the Si alloy. According to the mass percentage of 91.90%Al, 5.06%Mg, 2.94%Si and 0.10%Er, weigh 1201.04g of aluminum ingot with a purity of 99.96%, 215.06g of Al-40Mg master alloy block, 249.90g of Al-Si master alloy block and 34.00g of Al -Er intermediate alloy block, as a raw material for making alloy ingots, the total mass of ingredients is 1700g. After the various prepared raw materials have been cleaned and dried, first put 1201.04g of aluminum ingots and 249.90g of Al-Si intermediate alloy blocks into a graphite crucible resistance furnace, heat them, and cool down to 700°C after they are completely melted at 720°C. Add the g Al-Mg intermediate alloy block into the melt until it melts, and let it stand for 5 minutes. Press 0.2% hexachloroethane into the melt with a graphite bell jar preheated at 300°C, stir at 740°C to remove scum on the surface of the melt. 34.00 g of Al-Er master alloy ingots were added to the melt at 740°C. After me...

Embodiment 3

[0038] Al-8Mg 2 Add 0.30% Er to the Si alloy. According to the mass percentage of 91.70%Al, 5.06%Mg, 2.94%Si and 0.30%Er, weigh 1133.04g of aluminum ingot with a purity of 99.96%, 215.06g of Al-40Mg master alloy block, 249.90g of Al-Si master alloy block and 102.00g of Al -Er intermediate alloy block, as a raw material for making alloy ingots, the total mass of ingredients is 1700g. After the various prepared raw materials have been cleaned and dried, first put 1133.04g of aluminum ingots and 249.90g of Al-Si intermediate alloy blocks into a graphite crucible resistance furnace, heat them, and cool down to 700°C after they are completely melted at 720°C. Add the g Al-Mg intermediate alloy block into the melt until it melts, and let it stand for 5 minutes. Press 0.2% hexachloroethane into the melt with a graphite bell jar preheated at 300°C, stir at 740°C to remove scum on the surface of the melt. 102.00 g of Al-Er master alloy ingots were added to the melt at 720°C. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com