Coal gangue porous soil conditioner and preparation method thereof

A soil conditioner, coal gangue technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., to prevent soil erosion, facilitate plant growth, and increase water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

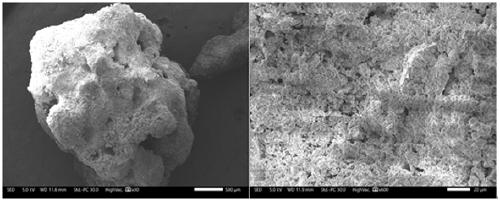

[0026] The raw materials and formula of this embodiment are: 96% of coal gangue powder under a 100-mesh sieve, 4% of ordinary silicon 42.5 cement, 0.1% of aluminum powder, and a water-cement ratio of 0.62. The preparation process is as follows: first grind the coal gangue raw materials to a 100-mesh sieve, then quantitatively weigh 960g of coal gangue powder, 40g of ordinary silicon 42.5 cement, 1g of aluminum powder, and 620g of tap water; Add it into the mixing tank and stir for 5 minutes at a speed of 800 rpm; then add a foaming agent and continue stirring for 30 seconds at a stirring speed of 1200 rpm; then quickly pour the slurry into a 100×100×200 mm In the steel mold, stop foaming for 30 minutes; put the foam and the mold together in the curing box for curing, the curing temperature is 50 ° C, and the curing time is 20 hours; take out the foam and the mold from the oven, and Remove the foam block from the mold, and place it in an oven at 105°C for 20 hours; then put the...

Embodiment 2

[0028] The raw materials and formula of this embodiment are: 93% of coal gangue powder under a 100-mesh sieve, 7% of ordinary silicon 42.5 cement, 0.3% of aluminum powder, and a water-cement ratio of 0.7. The preparation process is as follows: first grind the coal gangue raw materials to 100-mesh sieve, then quantitatively weigh 930g of coal gangue powder, 70g of ordinary silicon 42.5 cement, 3g of aluminum powder, and 700g of tap water; Add it into the mixing tank and stir for 5 minutes at a speed of 800 rpm; then add a foaming agent and continue stirring for 30 seconds at a stirring speed of 1200 rpm; then quickly pour the slurry into a 100×100×200 mm In the steel mold, stop foaming for 30 minutes; put the foam and the mold together in the curing box for curing, the curing temperature is 40 ° C, and the curing time is 25 hours; take out the foam and the mold from the oven, and Remove the foam block from the mold, and place it in an oven at 105°C for 30 hours; then put the dr...

Embodiment 3

[0030] The raw materials and formula of this embodiment are: 90% coal gangue powder under a 100-mesh sieve, 10% ordinary silicon 42.5 cement, 0.3% aluminum powder, and a water-cement ratio of 0.7. The preparation process is as follows: first grind the coal gangue raw materials to 100-mesh sieve, then quantitatively weigh 900g of coal gangue powder, 100g of ordinary silicon 42.5 cement, 3g of aluminum powder, and 700g of tap water; Add it into the mixing tank and stir for 5 minutes at a speed of 800 rpm; then add a foaming agent and continue stirring for 30 seconds at a stirring speed of 1200 rpm; then quickly pour the slurry into a 100×100×200 mm In the steel mold, stop foaming for 30 minutes; put the foam and the mold together into the curing box for curing, the curing temperature is 50 ° C, and the curing time is 15 hours; take out the foam and the mold from the oven, and Remove the foam block from the mold, and place it in an oven at 105°C for 20 hours; then put the dried f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com