Preparation method of silica gel pad

A technology of silicone pads and preparation steps, applied in chemical instruments and methods, materials for heat exchange, etc., can solve the problems of low withstand voltage performance, slow curing speed, low heat resistance, etc., and achieve small concentration changes and strong adhesion. The effect of not reducing the force and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

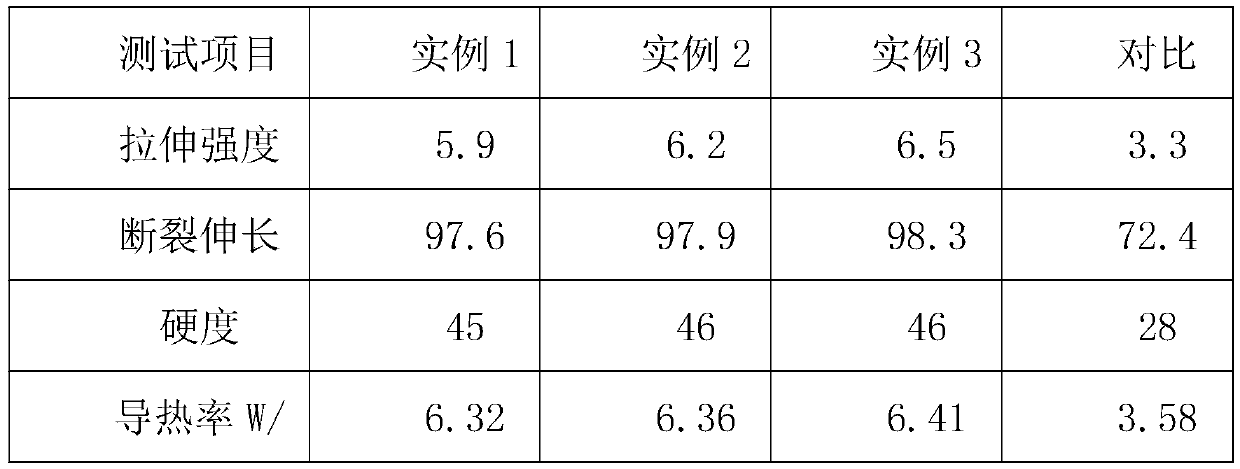

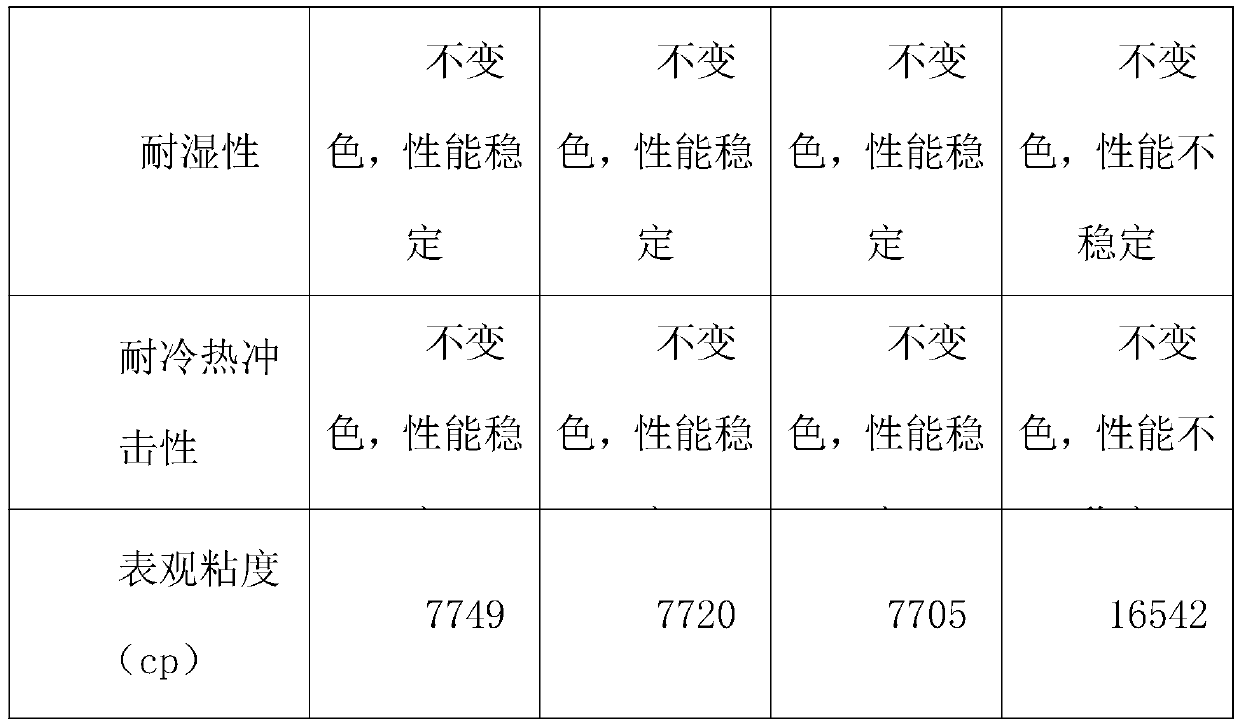

Examples

example 1

[0027]Boron oxide, silicon dioxide, aluminum oxide, zinc oxide, and polyvinyl alcohol solution with a mass fraction of 30% are mixed and ball milled in a mass ratio of 1:1:3:5:20 to obtain a ball mill slurry, and the obtained ball mill material particles are controlled The diameter is 0.1mm, the obtained ball mill slurry is poured into a flat mold, and then the flat mold is put into a press and pressed at a pressure of 8 MPa for 5 minutes, then put into a resistance furnace, heated to 1050°C, and kept for sintering for 1 hour. After continuing to raise the temperature to 1200°C at the same heating rate, immediately cool down naturally to 1050°C, heat-preserve and sinter for 1 hour, release the mold after naturally cooling to room temperature, crush and grind to obtain soft magnetic insulating powder; Add 50 parts of distilled water, 10 parts of sodium dodecylsulfonate, and 4 parts of sodium bicarbonate to the polymerization reactor, start the stirrer to stir at a speed of 200r / ...

example 2

[0029] Boron oxide, silicon dioxide, aluminum oxide, zinc oxide, and polyvinyl alcohol solution with a mass fraction of 30% are mixed and ball milled in a mass ratio of 1:1:3:5:20 to obtain a ball mill slurry, and the obtained ball mill material particles are controlled The diameter is 0.2mm, and the obtained ball mill slurry is poured into a flat mold, and then the flat mold is put into a press and pressed at a pressure of 9 MPa for 7 minutes, then put into a resistance furnace, heated to 1075°C, and kept for sintering for 2 hours. After continuing to raise the temperature to 1225°C at the same heating rate, immediately cool down naturally to 1075°C, heat-preserve and sinter for 2 hours, release the mold after naturally cooling to room temperature, crush and grind to obtain soft magnetic insulating powder; Add 55 parts of distilled water, 13 parts of sodium dodecylsulfonate, and 5 parts of sodium bicarbonate to the polymerization reactor, start the stirrer to stir at a speed o...

example 3

[0031] Boron oxide, silicon dioxide, aluminum oxide, zinc oxide, and polyvinyl alcohol solution with a mass fraction of 30% are mixed and ball milled in a mass ratio of 1:1:3:5:20 to obtain a ball mill slurry, and the obtained ball mill material particles are controlled The diameter is 0.3mm, and the obtained ball mill slurry is poured into a flat mold, and then the flat mold is put into a press and pressed at a pressure of 10MPa for 8 minutes, then put into a resistance furnace, heated to 1100°C, and kept for sintering for 2 hours. Continue to raise the temperature to 1250°C at the same heating rate, immediately cool down naturally to 1100°C, heat-preserve and sinter for 2 hours, let it cool naturally to room temperature, demould, crush and then grind to obtain soft magnetic insulating powder; Add 60 parts of distilled water, 15 parts of sodium dodecylsulfonate, and 5 parts of sodium bicarbonate to the polymerization reactor, start the stirrer to stir at a speed of 220r / min, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com