Anti-static dust-sticking pad and preparation method thereof

An anti-static and dust mat technology, which is applied in the field of sticky mats, can solve the problems of reducing the effect of sticking dust, achieve the effects of reducing firmness, improving the effect of sticking dust, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

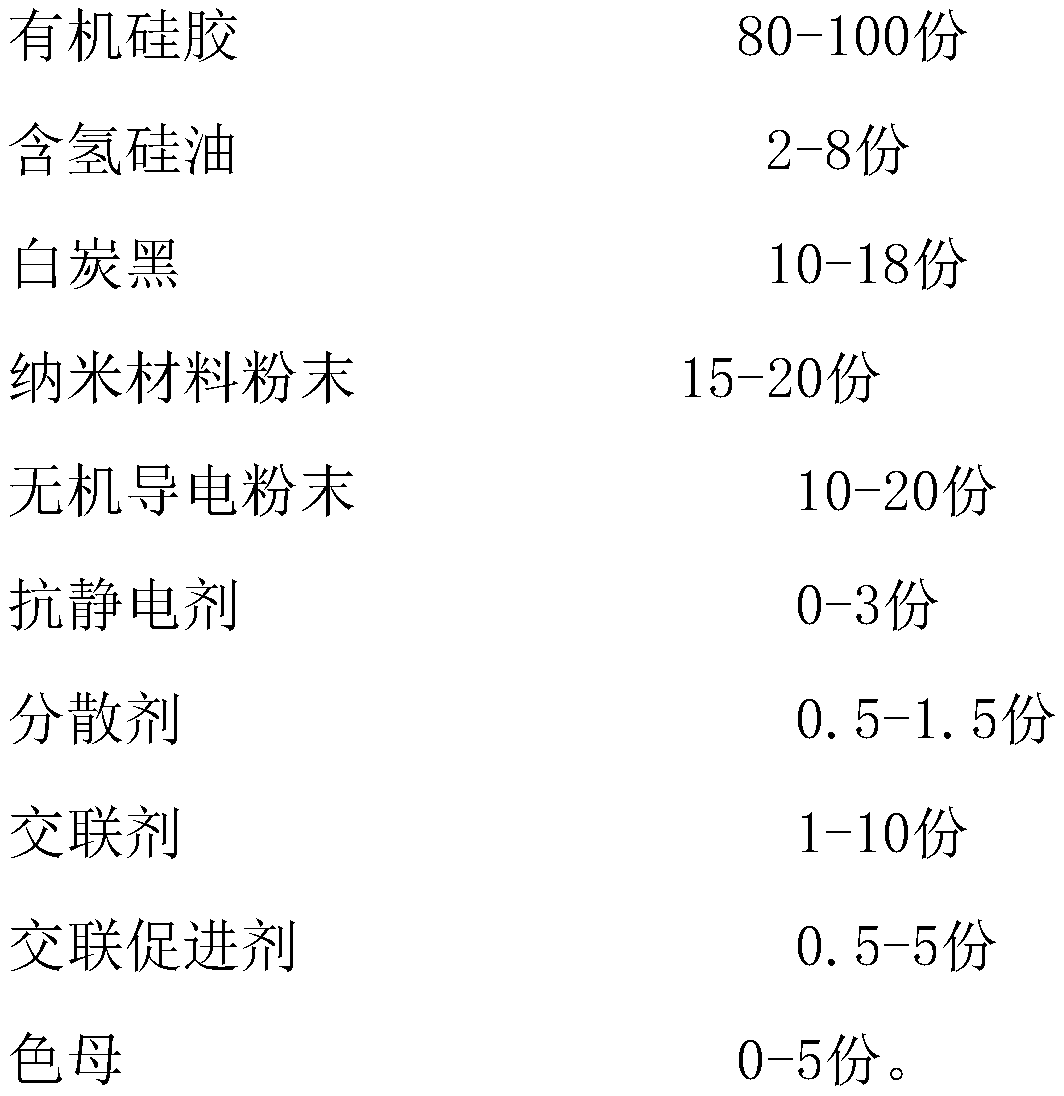

[0038] An antistatic sticky dust mat, comprising a sticky dust mat body, the surface of the sticky dust mat body is distributed with several nano-scale suction holes; the anti-static sticky dust mat is prepared from component A and nano-scale suction hole generating liquid As, the component A includes the following raw materials in parts by weight:

[0039]

[0040] The organic silica gel is methyl vinyl silicone rubber; the hydrogen-containing silicone oil is hydrogen-containing silicone oil with hydrogen-carrying side chains.

[0041] The cross-linking agent is formed by mixing ethyl orthosilicate and dicumyl peroxide at a weight ratio of 5:1; the cross-linking accelerator is dibutyltin dilaurate.

[0042] The nano-material powder is nano-alumina powder; the particle size of the nano-material powder is 10nm.

[0043] The specific surface area of the white carbon black is 200m 2 / g; the white carbon black is a modified white carbon black that has been soaked in a coupl...

Embodiment 2

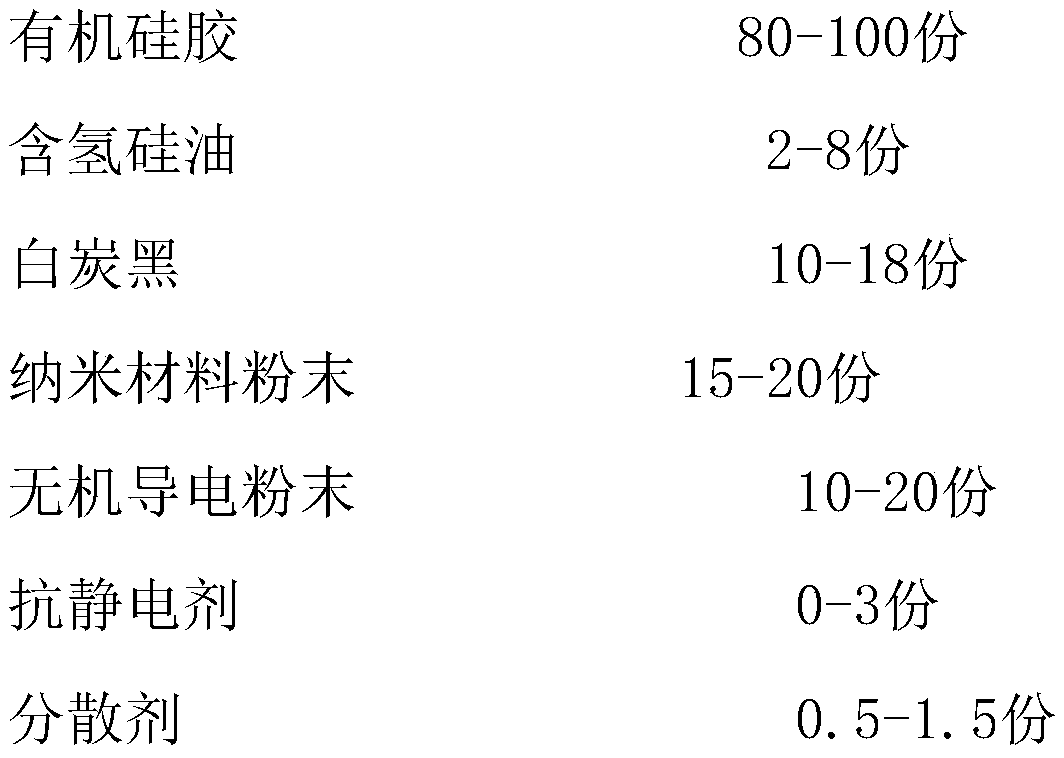

[0055] An antistatic sticky dust mat, comprising a sticky dust mat body, the surface of the sticky dust mat body is distributed with several nano-scale suction holes; the anti-static sticky dust mat is prepared from component A and nano-scale suction hole generating liquid As, the component A includes the following raw materials in parts by weight:

[0056]

[0057] The organic silica gel is methyl vinyl silicone rubber; the hydrogen-containing silicone oil is a hydrogen-containing silicone oil with methyl-terminated side chains carrying hydrogen.

[0058] The crosslinking agent is ethyl orthosilicate; the crosslinking accelerator is dibutoxydibutylstannane.

[0059] The nano-material powder is a mixture of nano-calcium carbonate powder and nano-magnesia powder in a weight ratio of 3:1; the particle size of the nano-material powder is 0.1 nm.

[0060] The specific surface area of the white carbon black is 100m 2 / g; the white carbon black is a modified white carbon blac...

Embodiment 3

[0071] An antistatic sticky dust mat, comprising a sticky dust mat body, the surface of the sticky dust mat body is distributed with several nano-scale suction holes; the anti-static sticky dust mat is prepared from component A and nano-scale suction hole generating liquid As, the component A includes the following raw materials in parts by weight:

[0072]

[0073] The organic silica gel is methyl vinyl silicone rubber; the hydrogen-containing silicone oil is hydrogen-containing silicone oil with hydrogen-carrying side chains.

[0074] The crosslinking agent is benzoyl peroxide; the crosslinking accelerator is dibutyldiphenoxytin and dibutylbis(2-phenylphenoxy)tin mixed in a weight ratio of 1:1. become.

[0075] The nano-material powder is formed by mixing nano-alumina powder and nano-zinc oxide powder at a weight ratio of 1:1; the particle size of the nano-material powder is 100 nm.

[0076] The specific surface area of the white carbon black is 300m 2 / g; the white ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com