Nanometer molecular sieve, synthetic method and applications thereof

A technology of nano-molecular sieve and synthesis method, which is applied in the field of nano-molecular sieve and its synthesis, which can solve the problems of small specific surface area, large particle size, and unfriendly environment, and achieve the effect of large specific surface area, small particle size, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 40 grams of silica sol (40%), 5 milliliters of ammonia, 2 grams of sodium hydroxide and 50 milliliters of deionized water were mixed and stirred at room temperature for 1 hour to form solution A, 0.5 grams of aluminum nitrate and 30 milliliters of water were stirred and dissolved to form solution B. Solution A was slowly added to solution B and stirred vigorously for 2 hours to obtain mixture C.

[0051] Take out 10% of mixture C, age at 100°C for 5 hours, add the remaining mixture C and 65 ml of ammonia water, stir vigorously for 2 hours, transfer this mixed system into a stainless steel crystallization kettle, and crystallize at 190°C for 12 hours , obtained crystallized powder D after rapid cooling, filtration, washing and drying.

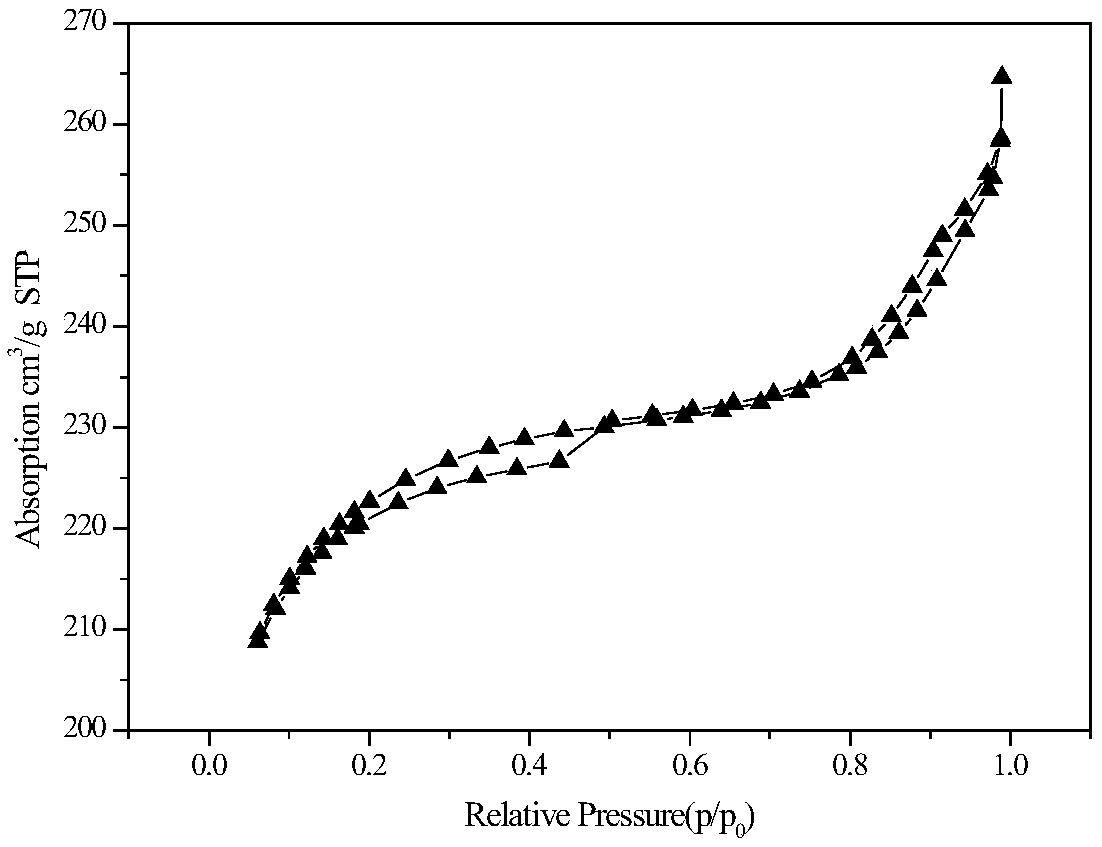

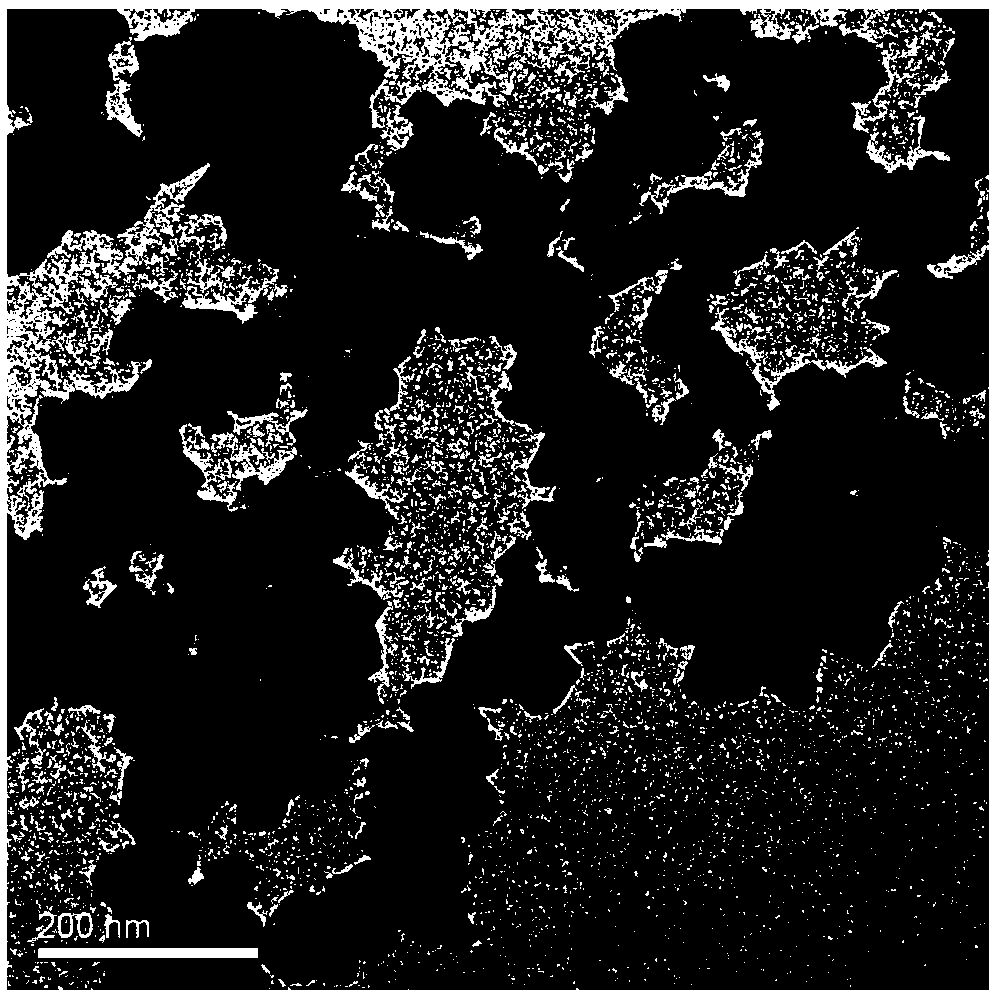

[0052] The obtained D powder was calcined at 500°C in a 100% water vapor atmosphere for 5. The XRD pattern of the obtained sample had the characteristic diffraction peak of ZSM-5 zeolite molecular sieve. The particle size of the molecular...

Embodiment 2

[0054] 4 grams of white carbon black, 2.5 milliliters of ammonia water, 1 gram of sodium hydroxide and 50 milliliters of deionized water were mixed, stirred at room temperature for 1 hour, and aged at 60° C. for 24 hours to obtain a mixture A.

[0055] 25 grams of tetraethyl orthosilicate, 20 milliliters of ammonia water, 1.5 grams of sodium hydroxide, 1.5 grams of aluminum sol (30%) and 20 grams of deionized water were mixed, stirred at room temperature for 24 hours to obtain mixture B,

[0056] Mix A and B, add 25 ml of ammonia water, stir vigorously for 2 hours, transfer the mixed system into a stainless steel crystallization kettle, crystallize at 190°C for 12 hours, and obtain crystallized powder C by quenching, filtering, washing, and drying.

[0057] The obtained C powder was calcined at 650°C for 10 hours in an air atmosphere containing 10% water vapor. The XRD pattern of the obtained sample had the characteristic diffraction peak of ZSM-5 zeolite molecular sieve, the p...

Embodiment 3

[0059] Stir 25 grams of deionized water, 5.2 grams of ammonia water, and 2.3 grams of aluminum isopropoxide until the solution becomes clear, add 1.5 grams of white carbon black, heat to 40° C. for 15 hours, and add 0.03 grams of sodium hydroxide. Crystallize at 120°C under autogenous pressure for 15 hours, cool, centrifuge, wash and dry to obtain a white powder, first calcined at 600°C for 15 hours in a nitrogen atmosphere, and then calcined at 700°C for 5 hours in a 100% water vapor atmosphere. The obtained XRD pattern has the characteristic diffraction peak of Y zeolite molecular sieve, the particle size is about 60nm, and the BET specific surface area is 800m 2 / g, the ratio of silicon to aluminum is 10.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com