Method for improving whiteness of oil shale semicoke through acid etching and aerobic calcination

A technology for oil shale semi-coke and calcination, which is applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem of lack of research reports and application precedents, which restricts the high-value utilization of oil shale semi-coke and affects product quality and other problems, to achieve the effect of mild reaction conditions, easy control of the process, and no discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

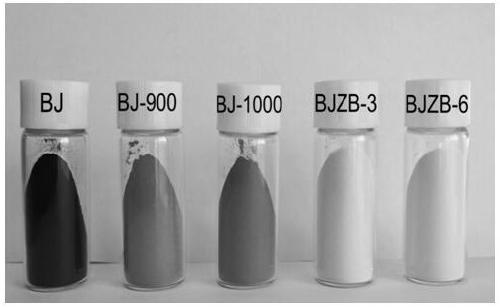

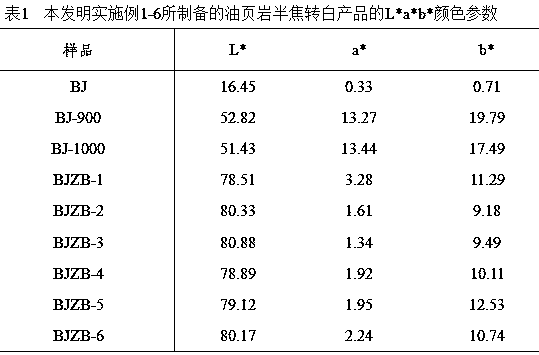

[0012] Weigh 60g of oil shale semi-coke powder, disperse into 300ml, 0.5mol / L hydrochloric acid solution, react at 60°C for 12h, centrifuge, wash with deionized water 5 times, press filter to obtain solid product, and control The moisture content of the solid product is 35%; the solid product is pressed into a thin sheet with a thickness of 0.5mm by using a double-roll machine for 3 times, and then calcined at 900°C for 2 hours in an air atmosphere to obtain an oil shale semi-coke-turned-white product , grind and sieve the whitening product, and mark it as BJZB-1, and its L*, a*, b* color parameters are shown in Table 1.

Embodiment 2

[0015] Weigh 60g of oil shale semi-coke powder, disperse into 1200ml, 2.0mol / L sulfuric acid solution, react at 60°C for 10h, centrifuge, wash with deionized water 5 times, press filter to obtain solid product, and control The moisture content of the solid product is 30%; the solid product is pressed into a sheet with a thickness of 1 mm by using a pair of rollers once, and then calcined at 1100 °C for 1 h in an air atmosphere to obtain the oil shale semi-coke turned white The product, the whitening product is ground and sieved, marked as BJZB-2, and its L*, a*, b* color parameters are shown in Table 1.

[0016] Comparative example: Weigh 60g of oil shale semi-coke powder and calcinate it at 1000°C for 2 hours in the air atmosphere to obtain a calcined sample of oil shale semi-coke, grind and sieve the calcined sample, and mark it as BJ-1000, its L *, a*, b* color parameters are shown in Table 1.

Embodiment 3

[0018] Weigh 60g of oil shale semi-coke powder, disperse into 600ml, 2mol / L hydrochloric acid solution, react at 90°C for 12h, centrifuge, wash with deionized water 5 times, press filter to obtain solid product, and control the solid product after press filtration The water content of the product is 33%; the solid product is pressed twice into a thin sheet with a thickness of 0.5mm by using a double-roller machine, and then calcined at 1000°C for 2 hours in an air atmosphere to obtain the oil shale semi-coke-turned-white product. The whitened product is ground and sieved, and marked as BJZB-3, and its L*, a*, b* color parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com