Anti-corrosion and anti-moth manufacturing method for composite solid wood floor

A technology of solid wood floor and manufacturing method, which is applied in the field of floor manufacturing, can solve the problems of shortened service life and moisture content deformation of composite solid wood floor, and achieve the effect of prolonged service life and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

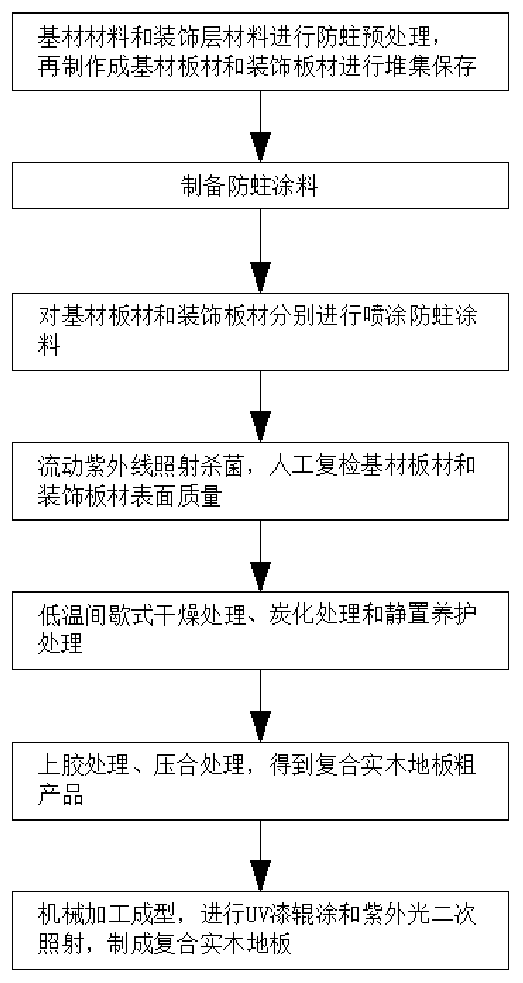

[0027] according to figure 1 As shown, the present embodiment proposes a method for manufacturing an anti-corrosion and moth-proof composite solid wood floor, comprising the following steps:

[0028] Step 1: Select non-valuable trees as the base material, and select valuable trees as the decorative layer material. After the base material and the decorative layer material are felled, the peeling operation is performed immediately, and then the anti-moth pretreatment is carried out respectively. The base material after the peeling operation The materials and decorative layer materials are sprayed with mothproof emulsion made of wood-specific insecticide and water at a ratio of 1:3, then sealed and covered with plastic film and stored for 3 days, and finally left to stand in the natural environment for 3 to 7 days Then make it into substrate boards and decorative boards for stacking and storage;

[0029] Step 2: According to the mass ratio, the ingredients are: 60 parts of styre...

Embodiment 2

[0036] according to figure 1 As shown, the present embodiment proposes a method for manufacturing an anti-corrosion and moth-proof composite solid wood floor, comprising the following steps:

[0037]Step 1: Select non-valuable trees as the base material, and select valuable trees as the decorative layer material. After the base material and the decorative layer material are felled, the peeling operation is performed immediately, and then the anti-moth pretreatment is carried out respectively. The base material after the peeling operation The materials and decorative layer materials are sprayed with mothproof emulsion made of wood-specific insecticide and water at a ratio of 1:3, then sealed and covered with plastic film and stored for 3 days, and finally left to stand in the natural environment for 3 to 7 days Then make it into substrate boards and decorative boards for stacking and storage;

[0038] Step 2: According to the mass ratio, the ingredients are: 65 parts of styren...

Embodiment 3

[0045] according to figure 1 As shown, the present embodiment proposes a method for manufacturing an anti-corrosion and moth-proof composite solid wood floor, comprising the following steps:

[0046] Step 1: Select non-valuable trees as the base material, and select valuable trees as the decorative layer material. After the base material and the decorative layer material are felled, the peeling operation is performed immediately, and then the anti-moth pretreatment is carried out respectively. The base material after the peeling operation The materials and decorative layer materials are sprayed with mothproof emulsion made of wood-specific insecticide and water at a ratio of 1:3, then sealed and covered with plastic film and stored for 3 days, and finally left to stand in the natural environment for 3 to 7 days Then make it into substrate boards and decorative boards for stacking and storage;

[0047] Step 2: According to the mass ratio, the ingredients are: 68 parts of styre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com