Calibration tool for a magnetic suction stamping tool holder chip detection device

A detection device, stamping technology, applied in positioning devices, manufacturing tools, clamping, etc., can solve the problem that the chip detection device does not have calibration tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

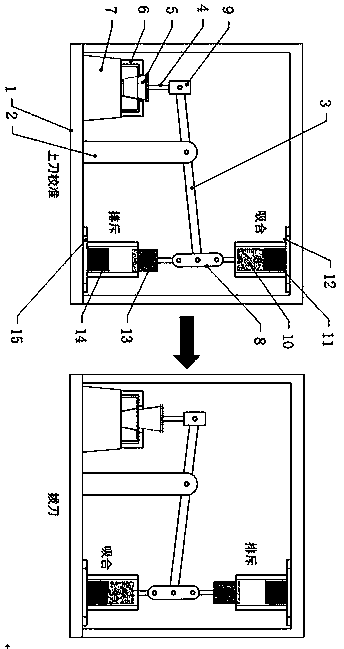

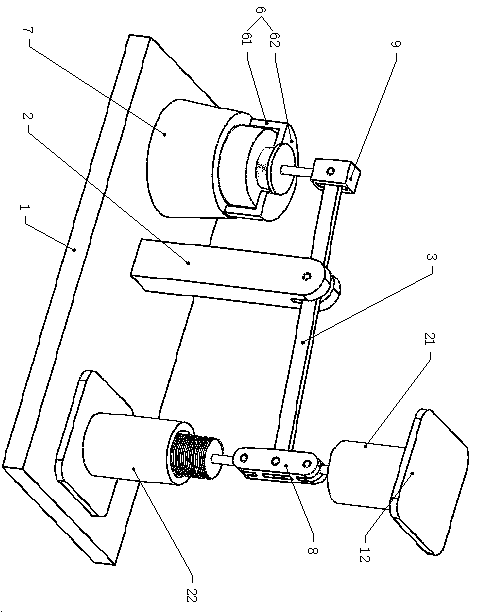

[0023] Embodiment 1, a calibration tool for a magnetic suction stamping tool holder chip detection device, including a calibration bench 1, a support arm 2, a lever 3, a fixed frame 6, a mounting seat 7, a power arm hinge connection block 8, and a resistance arm hinge Connecting block 9, top moving electromagnet 10, top fixed electromagnet 11 and top fixed seat 12.

[0024] The support arm 2 is set on the calibration bench 1, its upper end is hinged with the middle part of the lever 3, the front end of the lever 3 is hinged with the resistance arm hinge block 9, and its rear end is hinged with the power arm hinge block 8.

[0025] The top fixing seat 12 is installed on the top of the calibration stand 1, which extends downwards to form a top sleeve 21, the top fixed electromagnet 11 is fixedly installed on the top of the top sleeve 21, and the top moving electromagnet 10 can be arranged on the top sleeve so that it can slide up and down. In the cylinder 21, the lower end of th...

Embodiment 2

[0029] Embodiment 2, on the basis of Embodiment 1, further includes a bottom moving electromagnet 13 , a bottom fixing electromagnet 14 and a bottom fixing seat 15 . The bottom fixing seat 15 is installed on the bottom of the calibration stand 1, and it extends upwards to form a bottom sleeve 22. The bottom fixed electromagnet 14 is fixedly installed on the bottom of the bottom sleeve 22, and the bottom moving electromagnet 13 is arranged on the bottom sleeve so that it can slide up and down. 22, the upper end of the bottom motion electromagnet 13 is hinged with the power arm hinge connection block 8 through the connecting rod.

[0030] In this embodiment, through the upper and lower pairs of electromagnets, there are two functions. One is that the two pairs of electromagnets form a combined force to obtain a larger output of the upper knife force; the other is that the lower pair of electromagnets are in the process of drawing the knife. It can provide magnetic attraction to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com