A health state monitoring method for thermally conductive silicone grease and cooling fan

A technology of heat-conducting silicone grease and heat-dissipating fans, which is applied in the direction of measuring electricity, measuring devices, and thermal development of materials. It can solve problems such as the difficulty of achieving a thermal balance state, and achieve the effect of reducing costs and complexity of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

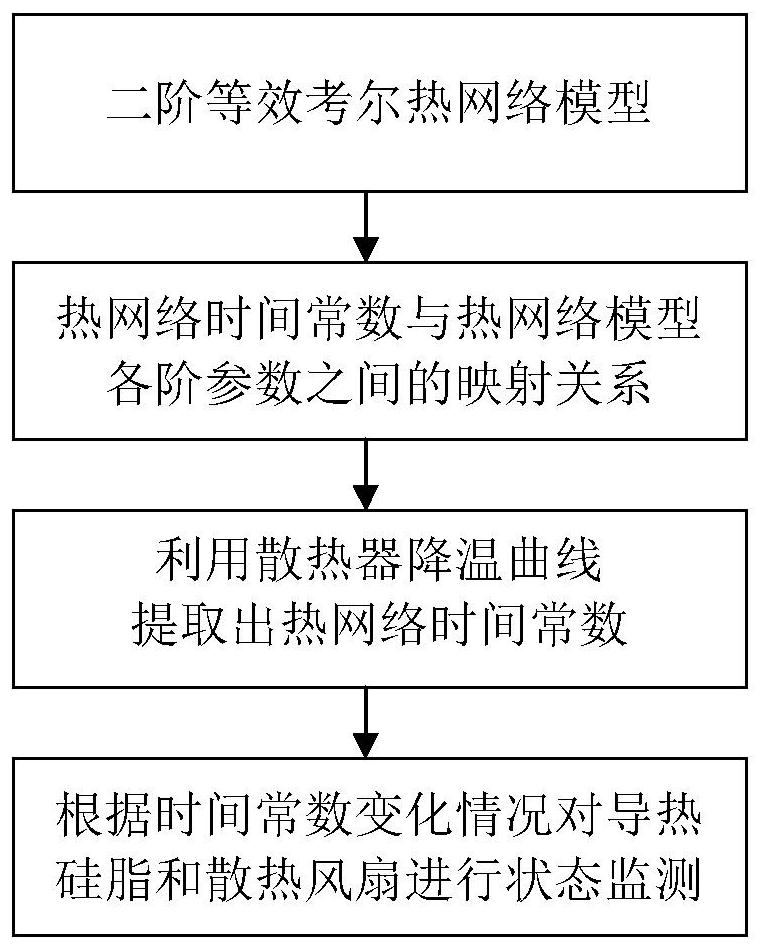

[0022] See figure 1 , which shows the health status monitoring method of thermal conductive silicone grease and cooling fan according to the present invention, including steps:

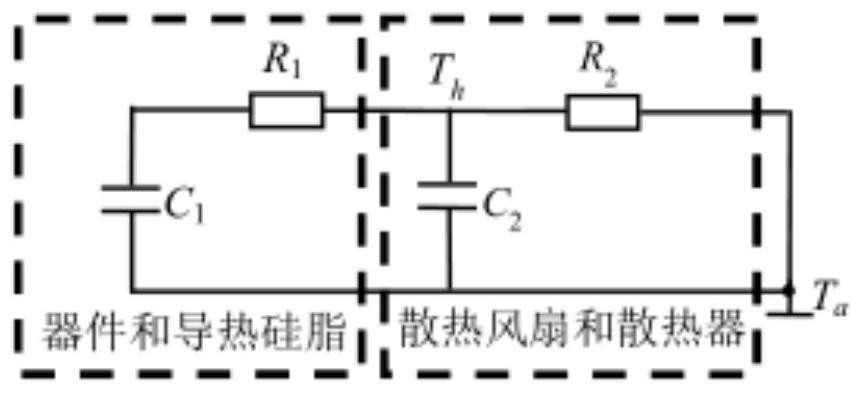

[0023] a. According to the physical connection structure of the device, thermal grease, heat sink and cooling fan, a second-order equivalent Caulier network model is established;

[0024] In this embodiment, step a specifically includes: according to the morphological structure formed by sequentially installing the device, thermal grease, radiator and cooling fan from top to bottom, divide the device and thermal grease into the first layer, the radiator and The cooling fan is divided into the second layer, and then the second-order equivalent Kaur heat network model is established, such as figure 2 shown.

[0025] b. According to the magnitude rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com