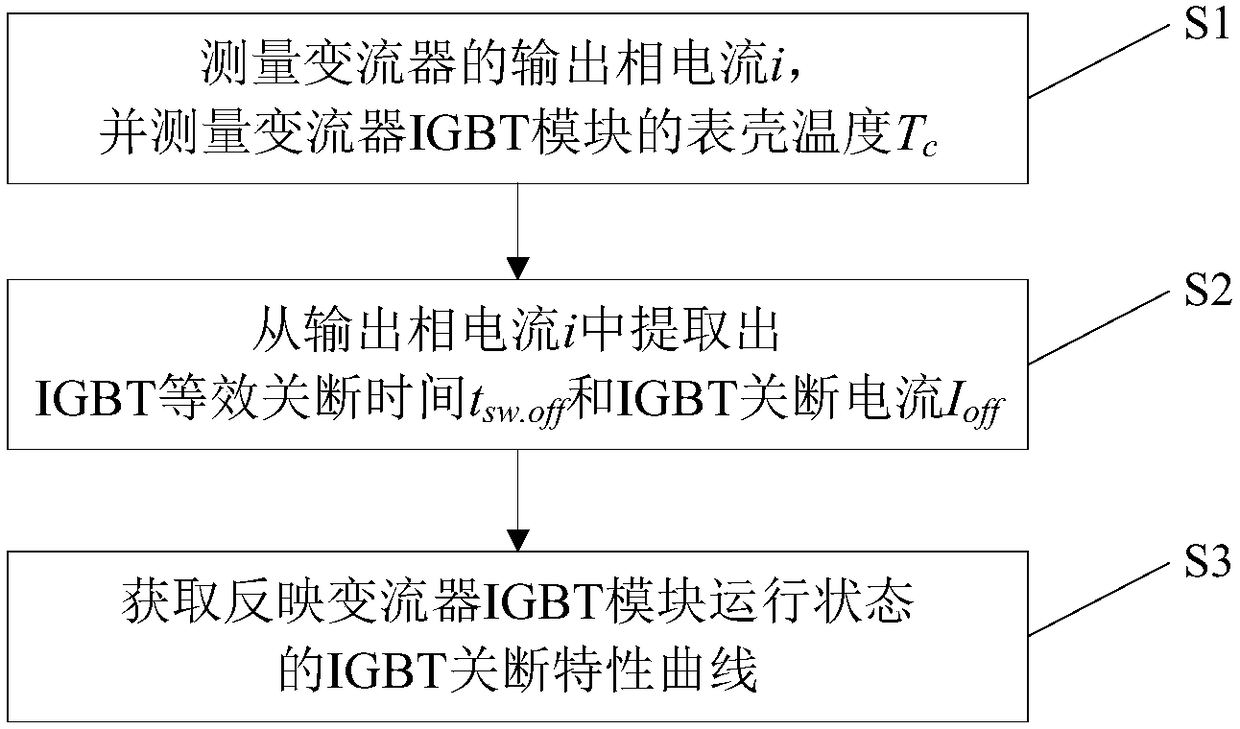

A non-contact converter igbt module state monitoring method

A non-contact, converter technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems such as difficult to accurately predict the life of converter IGBT modules, affect junction temperature estimation, etc., to achieve good applicability, engineering Ease of implementation and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

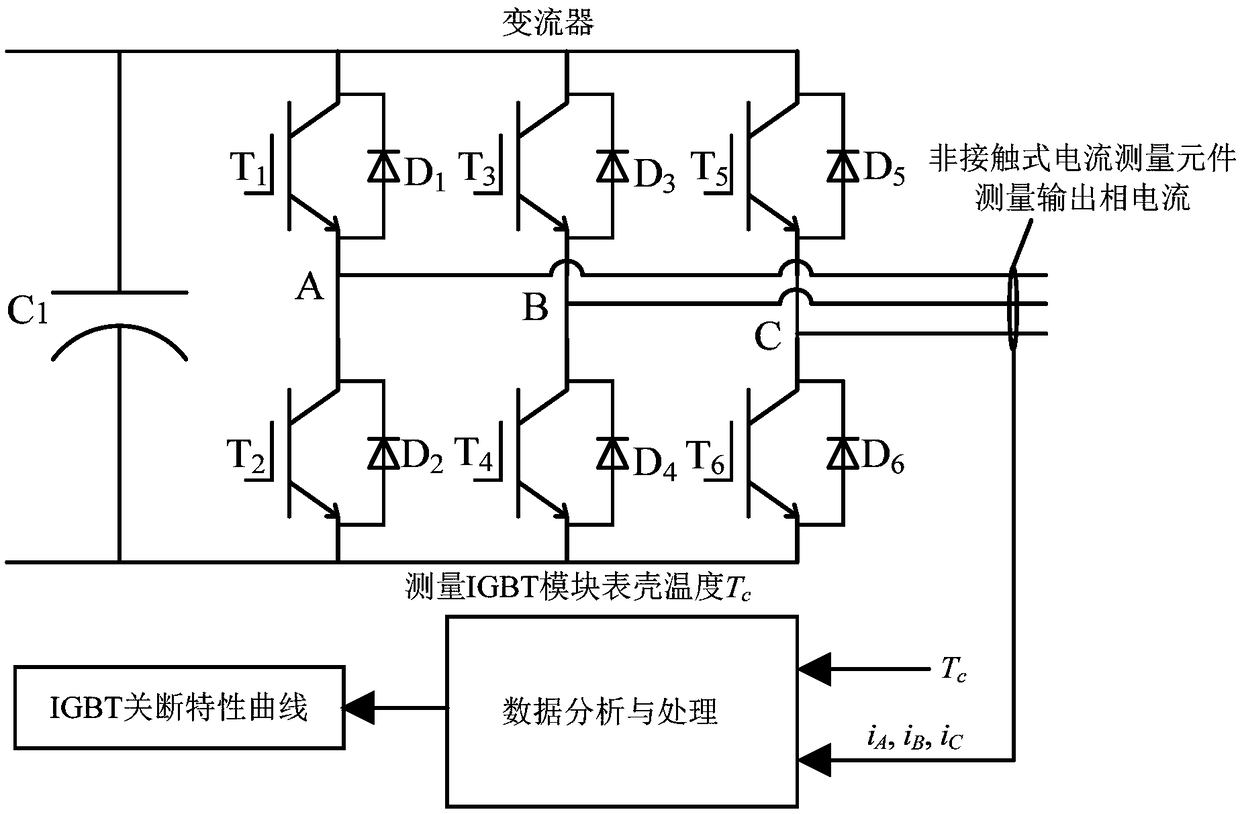

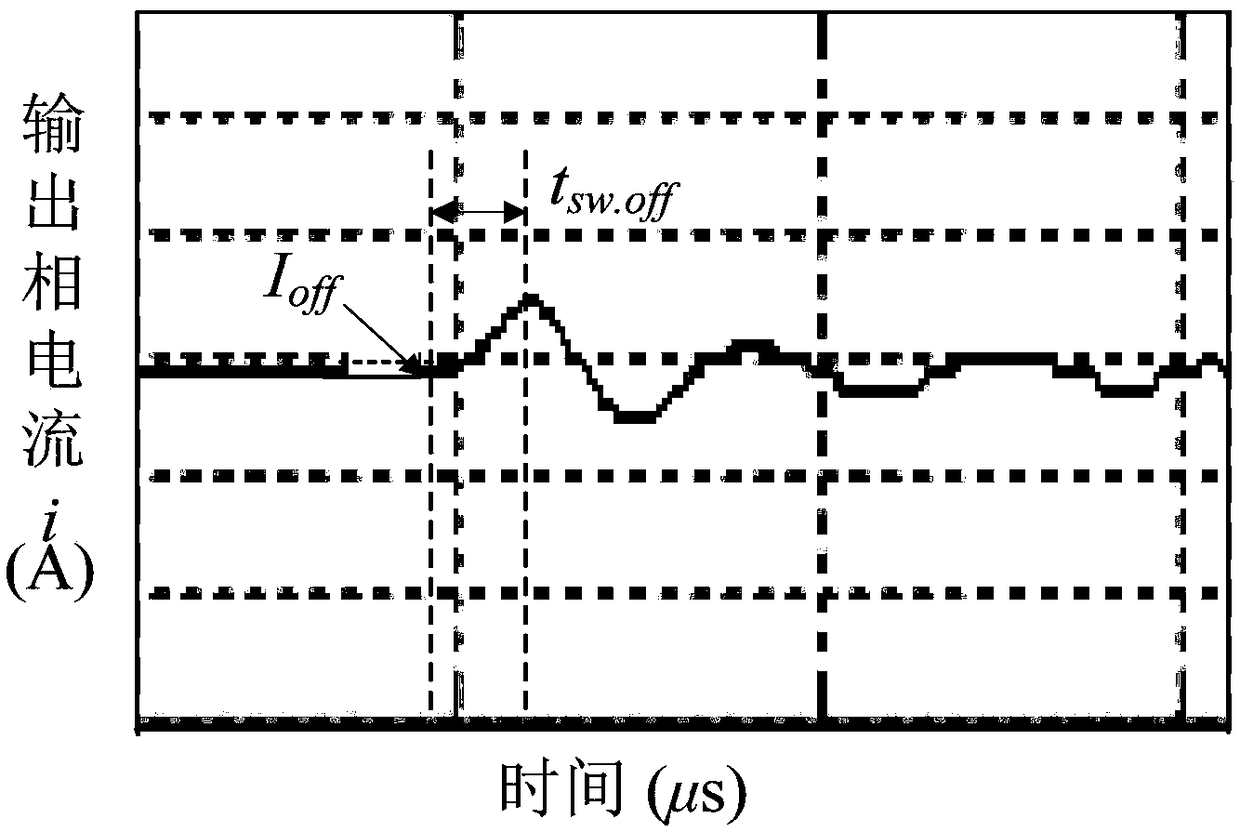

[0036] Example: the IGBT turn-off characteristic t of the IGBT module (FF50R12RT4) in the 380V / 10kW three-phase two-level converter before and after the fault is adopted by the inventive method sw.off =f(I off )taking the test. As the result of the experiment Figure 4 As shown, by comparing the IGBT turn-off characteristics f(I off ) can be found to change the health status of the IGBT module. The implementation process is as follows:

[0037] 1. Install a current probe at the A-phase output of the converter system. The current probe model is CP8030A with a bandwidth of 50MHz, which is used to measure the high-frequency oscillation signal in the output phase current of phase A of the converter and record the cut-off current I off . Use a thermocouple to measure the case temperature T of the IGBT module c . This patented method can monitor the state of all IGBT tubes in a certain phase bridge arm. If you need to monitor the IGBTs of other phase bridge arms, you only ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com