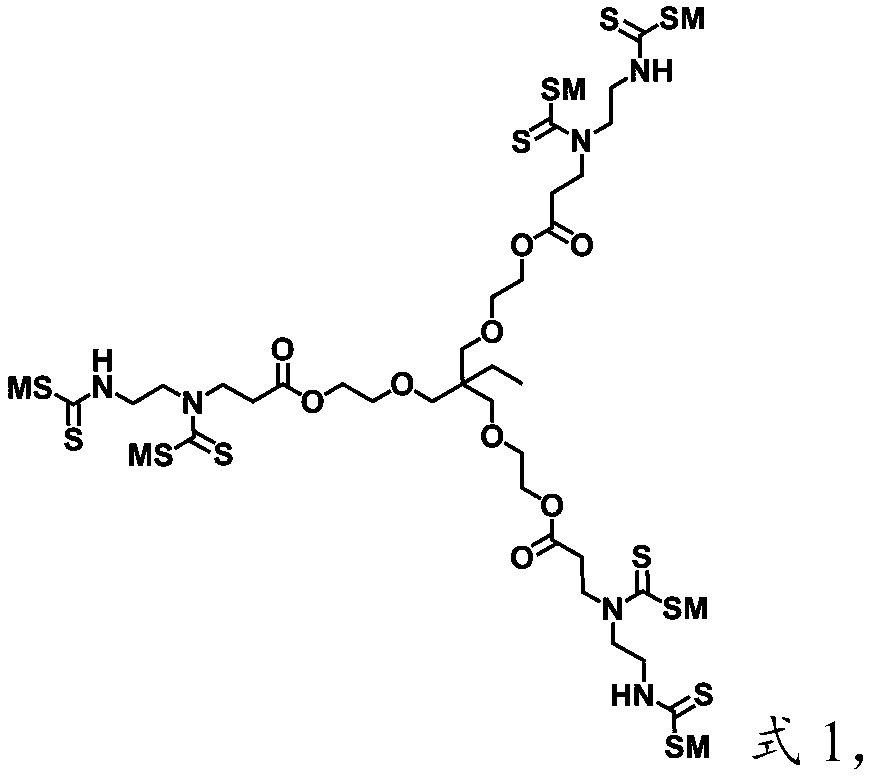

Ethoxylated trimethylolpropane core hyperbranched polymer taking dithiocarboxylate as side group and end group and application of chelating metal

A technology for ethoxylated trimethylolpropane and dithiocarboxylate, applied in organic chemistry, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of reduced utilization efficiency of chelating groups, DTC Low group utilization efficiency, affecting flocculation and sedimentation performance, etc., to achieve good chemical stability, fast sedimentation rate, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

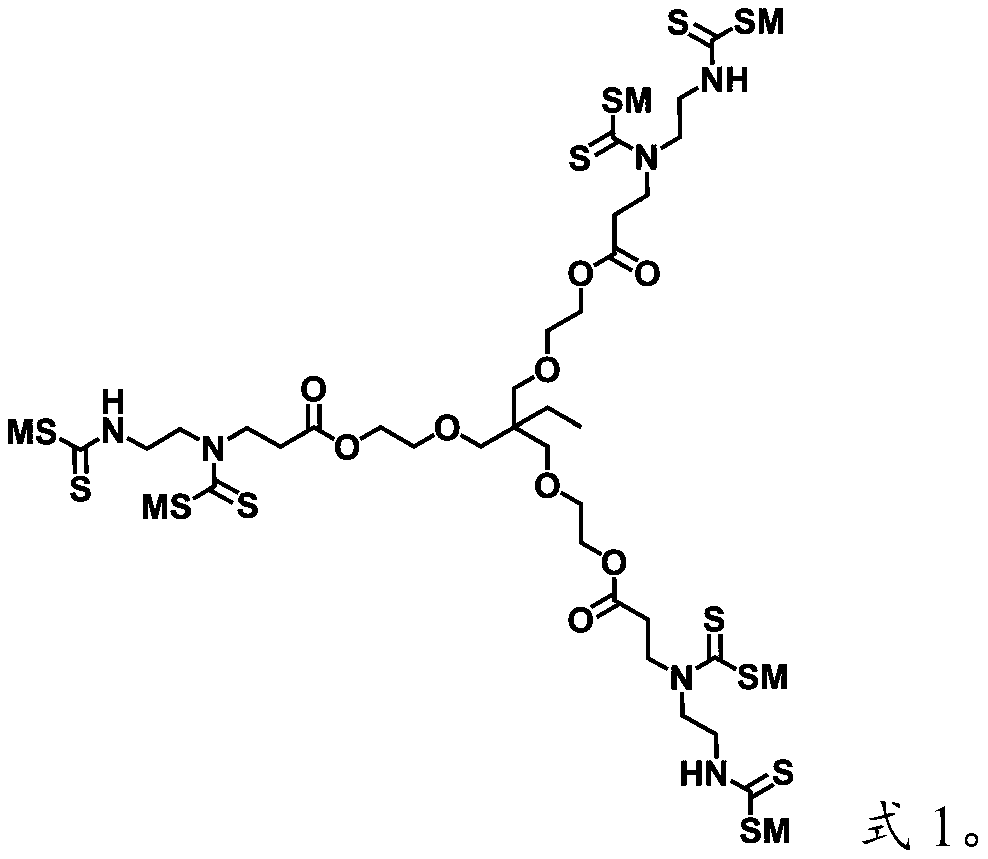

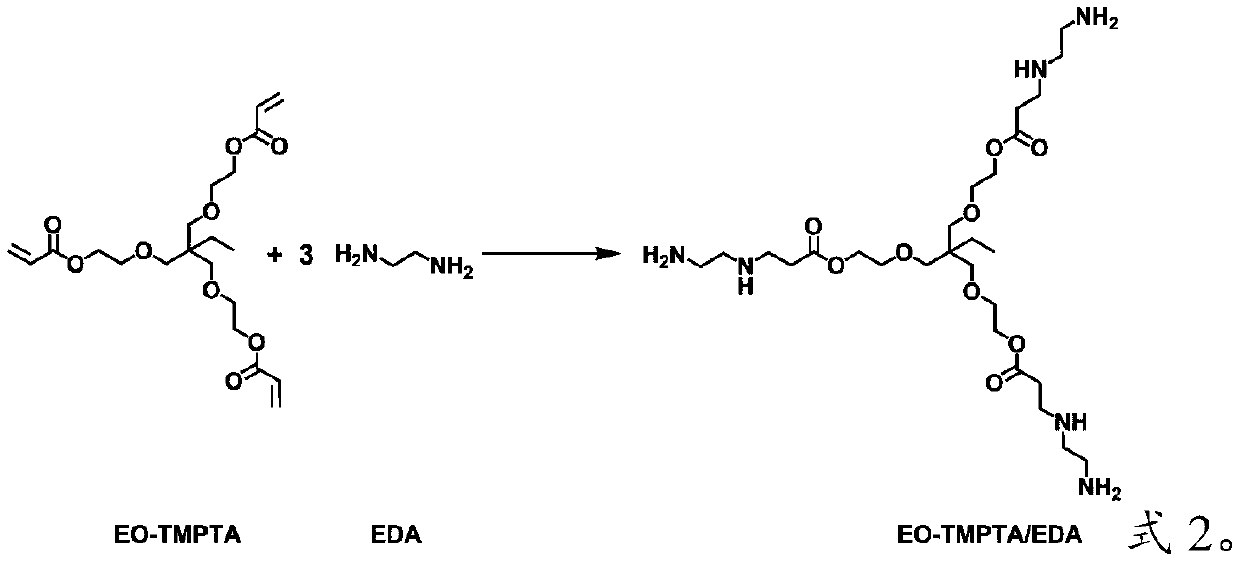

[0036] Under nitrogen protection, 36.00g (0.60mol) ethylenediamine (EDA) and 36.00g methanol are respectively added in the round bottom flask with stirring, reflux condenser, constant pressure dropping funnel and thermometer, start stirring and cooling to 5° C.; then through the dropping funnel, slowly dropwise add 85.60 g (0.10 mol, 50%) of a methanol solution of ethoxylated trimethylolpropane triacrylate (EO-TMPTA). After the dropwise addition was completed, the reaction was carried out at 25° C. for 24 hours. Then, under the condition of 95°C, distill under reduced pressure for 4 hours to distill off excess ethylenediamine and methanol to obtain a light amber viscous product, which is an intermediate: ethoxylated trimethylolpropane tri((N-( 2-aminoethyl))-3-aminopropionate) hyperbranched polymer (EO-TMPTA / EDA). Then, add 140.00g of deionized water, stir evenly, cool to 5°C, slowly add 48.00g (50%, 0.60mol) of sodium hydroxide aqueous solution through a constant pressure dr...

Embodiment 2

[0039] Under nitrogen protection, 48.00g (0.80mol) ethylenediamine (EDA) and 54.00g methanol were respectively added in the round bottom flask with stirring, reflux condenser, constant pressure dropping funnel and thermometer, started stirring and cooled to 5° C.; then through the dropping funnel, slowly dropwise add 85.60 g (0.10 mol, 50%) of a methanol solution of ethoxylated trimethylolpropane triacrylate (EO-TMPTA). After the dropwise addition was completed, the reaction was carried out at 25° C. for 20 hours. Then, under the condition of 95°C, distill under reduced pressure for 3 hours to distill off excess ethylenediamine and methanol to obtain a light amber viscous product, which is an intermediate: ethoxylated trimethylolpropane tri((N-( 2-aminoethyl))-3-aminopropionate) hyperbranched polymer (referred to as EO-TMPTA / EDA). Then, add 145.00g of deionized water, stir evenly, cool to 10°C, slowly add 49.60g (50%, 0.62mol) of sodium hydroxide aqueous solution through a co...

Embodiment 3

[0042] Under nitrogen protection, 18.00g (0.30mol) ethylenediamine (EDA) and 30.00g methanol were added respectively in the round bottom flask with stirring, reflux condenser, constant pressure dropping funnel and thermometer, started stirring and cooled to 5° C.; then through the dropping funnel, slowly dropwise add 42.80 g (0.05 mol, 50%) of a methanol solution of ethoxylated trimethylolpropane triacrylate (EO-TMPTA). After the dropwise addition was completed, the reaction was carried out at 25° C. for 24 hours. Then, under the condition of 95°C, distill under reduced pressure for 4 hours to distill off excess ethylenediamine and methanol to obtain a light amber viscous product, which is an intermediate: ethoxylated trimethylolpropane tri((N-( 2-aminoethyl))-3-aminopropionate) hyperbranched polymer (referred to as EO-TMPTA / EDA). Then, add 66.00g of deionized water, stir evenly, cool to 5°C, slowly add 24.00g (50%, 0.30mol) of sodium hydroxide aqueous solution through a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com