Lithium ion battery composite positive electrode material and preparation method thereof

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor conductivity, poor cycle performance, low Coulomb efficiency, etc., to improve stability and cycle performance, and structural stability. , the effect of good electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

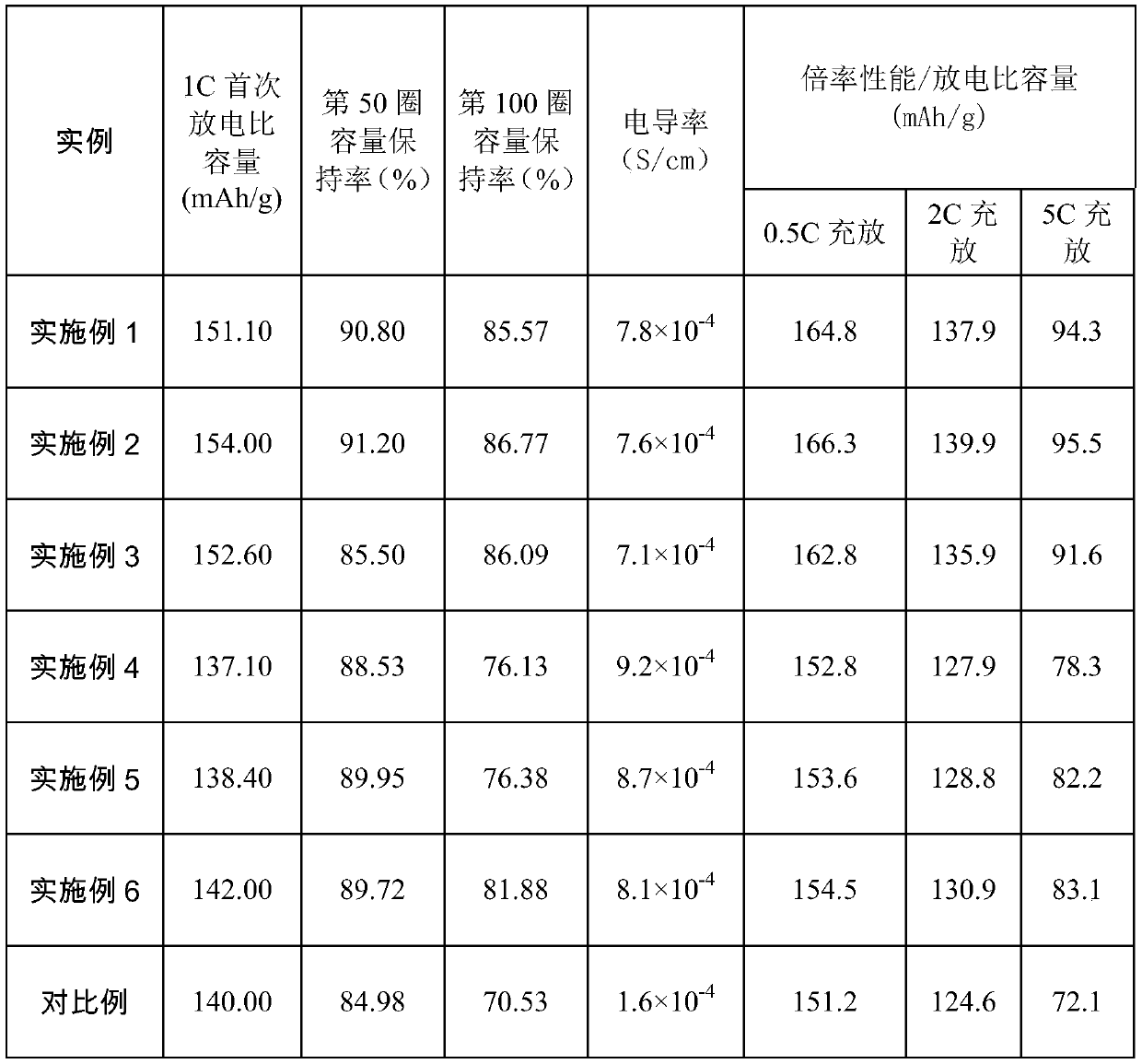

Examples

Embodiment 1

[0023] Step 1: Mix 20g of aluminum isopropoxide with 180g of absolute ethanol, heat and stir ultrasonically, the temperature is 60-80°C, and the stirring rate is 600r / min, until the aluminum isopropoxide is completely dissolved, and a uniform aluminum isopropoxide ethanol solution is obtained ;

[0024] Step 2: prepare zirconium nitrate and cerium nitrate mixed solution, the concentration of zirconium and cerium is 0.1mol / L;

[0025] Add the phosphoric acid aqueous solution with a mass percentage of 52% dropwise into the above-mentioned aluminum isopropoxide ethanol solution under stirring, and simultaneously add the above-mentioned mixed solution of zirconium nitrate and cerium nitrate, and stir while adding dropwise until a homogeneous colloid is formed; Add 0.05mol / L cetyltrimethylammonium bromide solution and stir well. Wherein, the molar ratio of aluminum isopropoxide, cerium, zirconium, phosphoric acid, and cetyltrimethylammonium bromide is 1:0.5:0.5:1:0.1.

[0026] Th...

Embodiment 2

[0038] Step 1: Mix 40g of aluminum isopropoxide with 200g of absolute ethanol, heat and stir ultrasonically, the temperature is 60-80°C, and the stirring rate is 600r / min, until the aluminum isopropoxide is completely dissolved, and a uniform aluminum isopropoxide ethanol solution is obtained ;

[0039] Step 2: prepare zirconium acetate and cerium acetate mixed solution, the concentrations of zirconium and cerium are both 0.1mol / L;

[0040] A phosphoric acid aqueous solution with a mass percent content of 54% was added dropwise to the above-mentioned aluminum isopropoxide ethanol solution under stirring, and at the same time, the mixed solution of zirconium acetate and cerium acetate prepared above was added, and stirred while adding dropwise until a homogeneous colloid was formed; Add 0.05mol / L nonylphenol ethoxylate-10 solution and stir evenly. Among them, the molar ratio of aluminum isopropoxide, cerium, zirconium, phosphoric acid, and nonylphenol ethoxylate-10 is 2:1:1:2:...

Embodiment 3

[0052] Step 1: Mix 20g of aluminum isopropoxide with 200g of absolute ethanol, heat and stir ultrasonically, the temperature is 60-80°C, and the stirring rate is 600r / min, until the aluminum isopropoxide is completely dissolved, and a uniform aluminum isopropoxide ethanol solution is obtained ;

[0053] Step 2: prepare zirconium sulfate and cerium sulfate mixed solution, the concentration of zirconium and cerium is 0.1mol / L;

[0054] A phosphoric acid aqueous solution with a mass percentage of 53% was added dropwise to the above-mentioned aluminum isopropoxide ethanol solution under stirring, and at the same time, the mixed solution of zirconium sulfate and cerium sulfate prepared above was added, and stirred while adding dropwise until a homogeneous colloid was formed; Add 0.05mol / L sodium dodecylbenzenesulfonate solution and stir well. Among them, the molar ratio of aluminum isopropoxide, cerium, zirconium, phosphoric acid, and sodium dodecylbenzenesulfonate is 1:1:1:1:0.1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com