A sewage tail water heat recovery device

A heat recovery device and tail water technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of difficult heat exchange unit power, reduced heat collection efficiency, adaptation, etc., to reduce maintenance frequency , avoid wasting energy, reduce the effect of being

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

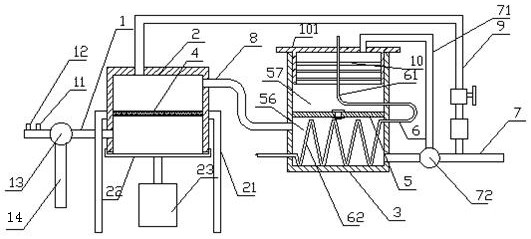

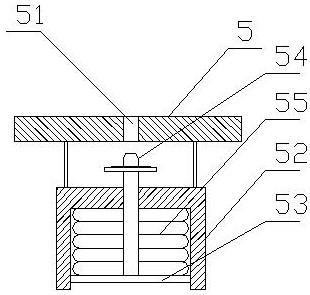

[0014] Such as figure 1 with figure 2 The shown sewage tail water heat recovery device includes a water supply pipe 1, a filter box 2 and a heat exchange box 3, the water supply pipe is connected to the filter box, and a filter screen 4 is arranged in the filter box; a partition is arranged in the middle of the heat exchange box 5. The partition divides the heat exchange box into a high-heat area 56 and a low-heat area 57. A permeable hole 51 is provided in the middle of the partition. A guide sleeve 52 opposite to the permeable hole is provided on the side of the high-heat area of the permeable hole. Inside the guide sleeve is a Sliding plate 53, the middle part of the sliding plate is connected with a sealing rod 54 opposite to the permeable hole, and the sliding plate is connected with an elastic airbag 55, and when the elastic airbag is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com