Composite micro-nano hollow fiber material as well as preparation method and application thereof

A technology of fiber materials and carbon nanofibers, which is applied in the field of composite micro-nano hollow fiber materials and its preparation, can solve the problems of reduced metal lithium negative electrode cycle efficiency, metal lithium consumption, battery performance damage, etc. Effect of growth and prevention of excessive deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 : Preparation of carbon micro-nano hollow fiber materials wrapped with nickel-cobalt alloy hollow nanoprisms

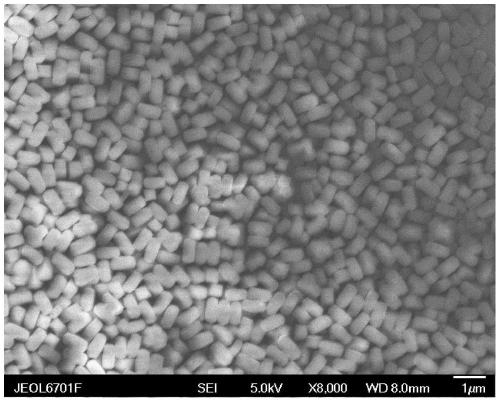

[0049] The polyvinylpyrrolidone (number average molecular weight: 40000) and the nickel acetate and cobalt acetate mixture with the molar ratio of nickel and cobalt elements of 1:2 were dissolved in ethanol at 25 ° C. The mass fraction of polyvinylpyrrolidone in the mixed solution was 1.5%, nickel The mass fraction of cobalt acetate is 1%, and the obtained mixed solution is heated to 65° C. to react for 1 hour, and the product is a nickel-cobalt-based acetate hydroxide precursor. Its scanning electron microscope photos such as figure 1 shown, by figure 1 It can be seen that the particle length size of the nickel-cobalt-based acetate hydroxide precursor is about 1.3 μm, and the width size is about 0.3 μm;

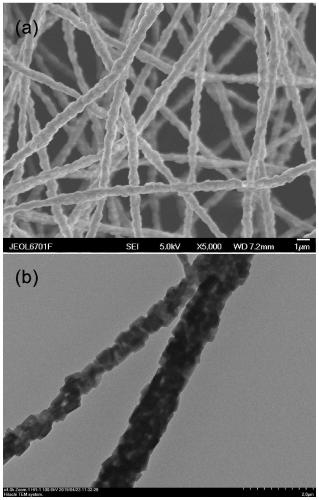

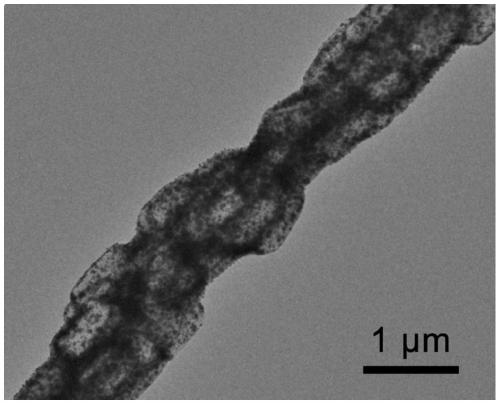

[0050] The nickel-cobalt-based acetate hydroxide precursor and polyacrylonitrile are respectively dispersed in N,N-dimethylformamide, and the t...

Embodiment 2

[0052] Example 2 : wrapped with Ni 5 CoS 4 Preparation of carbon micro-nano hollow fiber materials with hollow nanoprisms

[0053] The polyvinylpyrrolidone (number average molecular weight: 40000) and the nickel acetate and cobalt acetate mixture with the molar ratio of nickel and cobalt elements of 5:1 were dissolved in ethanol at 22 ° C, the mass fraction of polyvinylpyrrolidone in the mixed solution was 2%, nickel The mass fraction of cobalt acetate is 1.5%, and the obtained mixed solution is heated to 85° C. to react for 1 hour, and the product is the precursor of nickel-cobalt-based acetate hydroxide. The product particle has a length of about 1 μm and a width of about 0.5 μm;

[0054] The nickel-cobalt-based acetate hydroxide precursor and polyacrylonitrile are respectively dispersed in N,N-dimethylformamide, and the two precursor solutions are mixed to obtain a spinning solution, wherein the nickel-cobalt-based acetic acid The mass fraction of salt hydroxide precur...

Embodiment 3

[0056] Example 3 : Wrapped with NiCo 2 Preparation of carbon micro-nano hollow fiber materials of P hollow nanoprisms

[0057] Dissolve polyvinylpyrrolidone (number average molecular weight: 40000) and a mixture of nickel acetate and cobalt acetate with a molar ratio of nickel and cobalt elements of 1:2 in ethanol at 21 ° C, the mass fraction of polyvinylpyrrolidone in the mixed solution is 1.5%, nickel The mass fraction of cobalt acetate is 1.5%, and the obtained mixed solution is heated to 45° C. to react for 4 hours, and the product is the precursor of nickel-cobalt-based acetate hydroxide. The product particle has a length of about 1.2 μm and a width of about 0.2 μm;

[0058] The nickel-cobalt-based acetate hydroxide precursor and polyacrylonitrile are respectively dispersed in N,N-dimethylformamide, and the two precursor solutions are mixed to obtain a spinning solution, wherein the nickel-cobalt-based acetic acid The mass fraction of salt hydroxide precursor and poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com