Display substrate, use method of display substrate, and polymer electroluminescent device

A technology of electroluminescent devices and display substrates, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., and can solve the problem of low uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

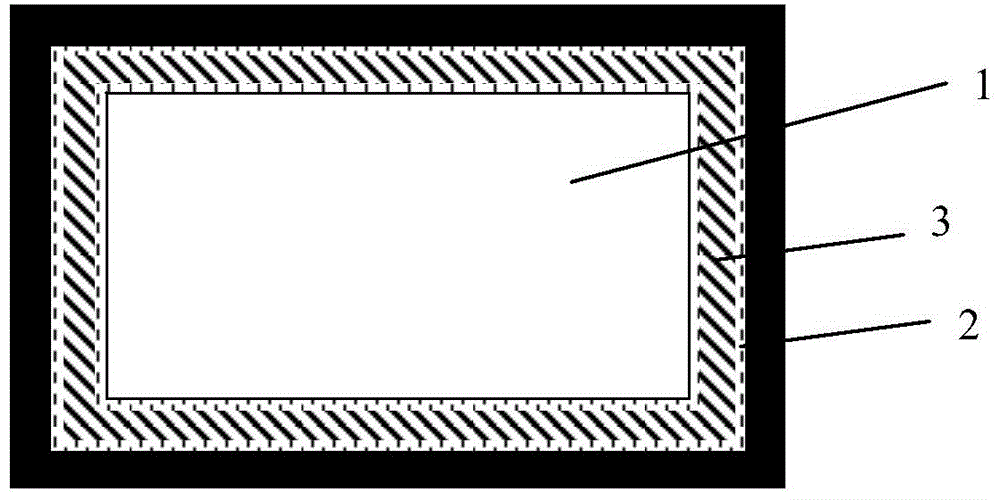

[0044] In this embodiment, the display substrate provided by the present invention is used to make a polymer electroluminescent device. The substrate is a 14-inch substrate, and the width of the dummy pixel area is the width of two pixels. A groove area is formed inside, and the width of the groove area is equal to the width of the dummy pixel area (that is, the width of two pixels).

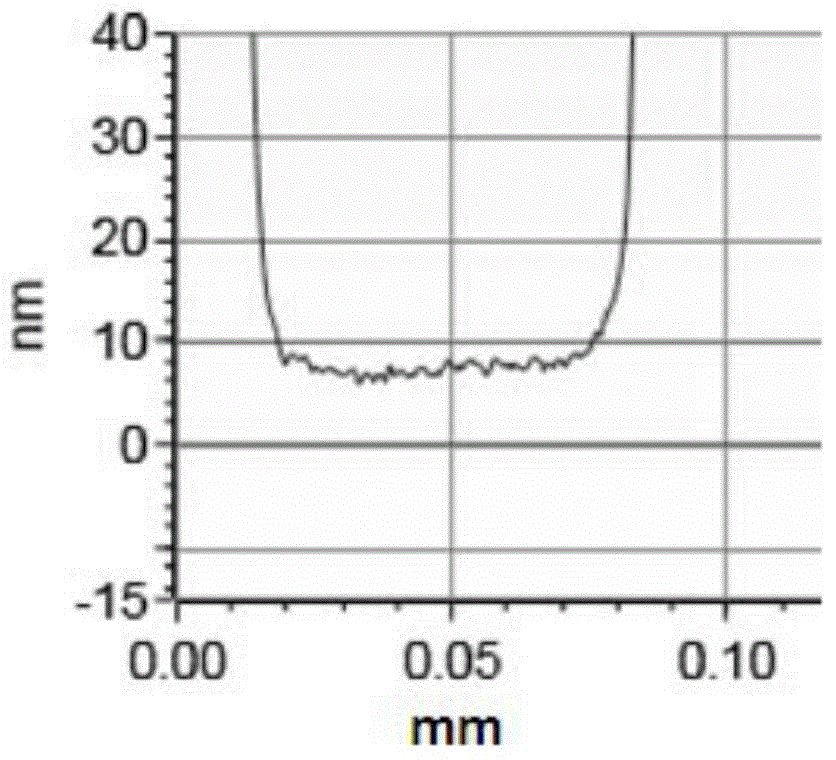

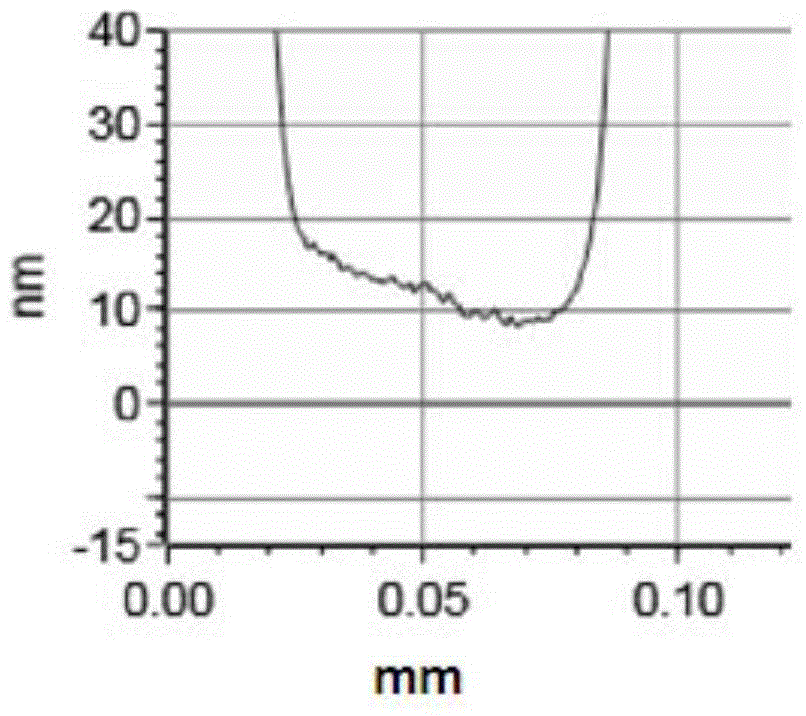

[0045] The process of making a polymer electroluminescent device by inkjet printing technology is as follows: using luminescent material as a solute and volatile organic matter as a solvent to prepare a second ink; mixing the second ink with 1,2-propylene glycol to prepare the first ink; Use glue dispensing technology to add the first ink to the groove area on the substrate, and keep adding the first ink in the groove area; use the second ink to perform inkjet printing on the light-emitting area, so that the second The ink dries to form a film, and finally forms a light-emitting unit; finally, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com