Heating furnace hearth pressure dynamic optimization control method based on furnace gas amount

A technology of dynamic optimization and control method, applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

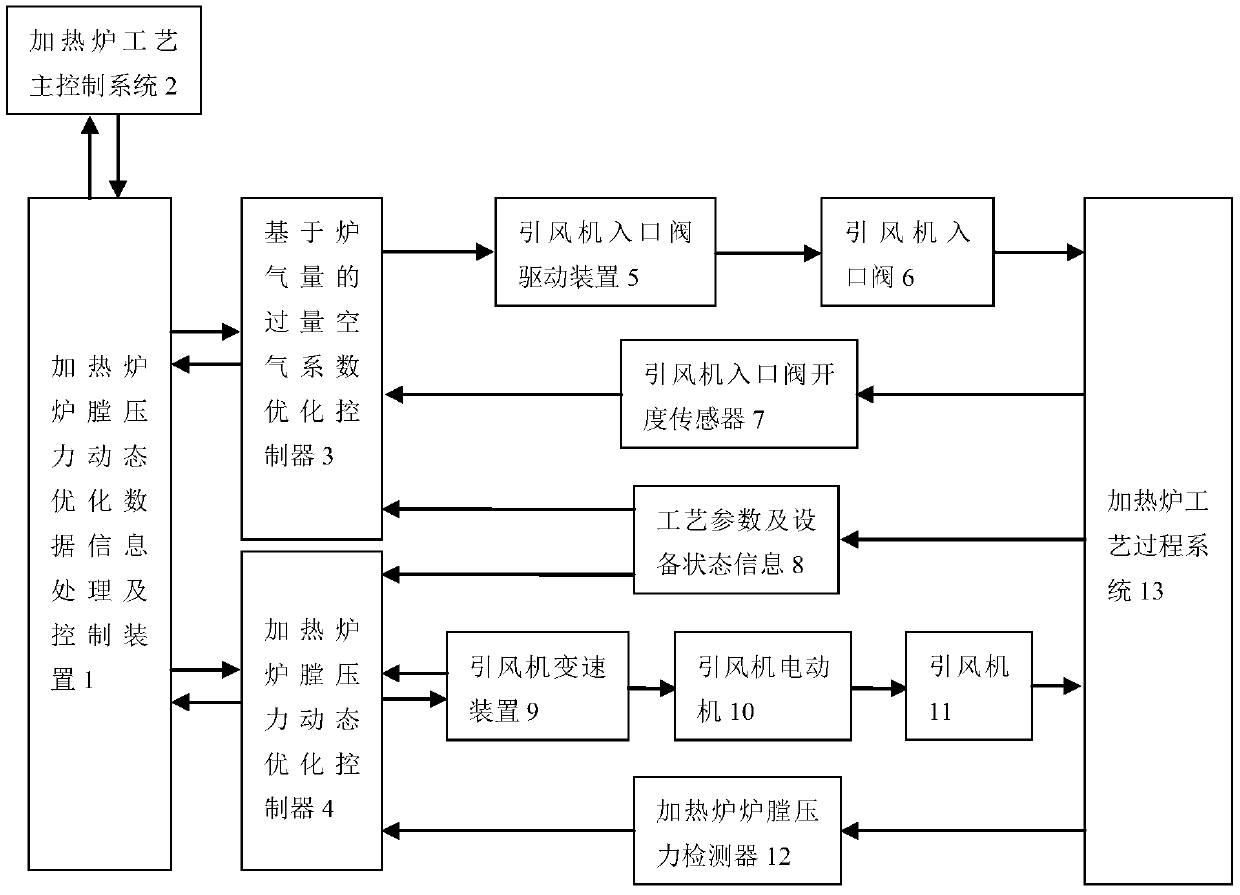

[0013] The system of dynamic optimal control method of furnace pressure based on furnace gas volume is composed of two control units, one control unit is based on the furnace gas volume excess air coefficient optimization control system, and the other control unit is to adjust the speed of the induced draft fan according to the furnace pressure detection Closed-loop dynamic system; adjust the opening of the inlet valve of the induced draft fan according to the furnace gas volume, so that the excess air coefficient can be effectively controlled, which is also conducive to the energy saving of the induced draft fan; on the premise that the opening of the induced draft fan inlet valve basically matches the furnace gas volume, The furnace pressure detection adjusts the speed of the induced draft fan, so that the furnace pressure is stably controlled within the required range, reducing or eliminating the overflow of flue gas in the heating furnace, reducing or eliminating the inhalat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com