A kind of high glass transition temperature water-based solvent-free polyurea coating material and preparation method thereof

A high vitrification, coating material technology, used in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problem of high energy consumption, acid and alkali resistance and liquid medium resistance of epoxy resin coatings are not as good as polyurea. and other problems, to achieve the effects of low energy consumption, excellent acid and alkali resistance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

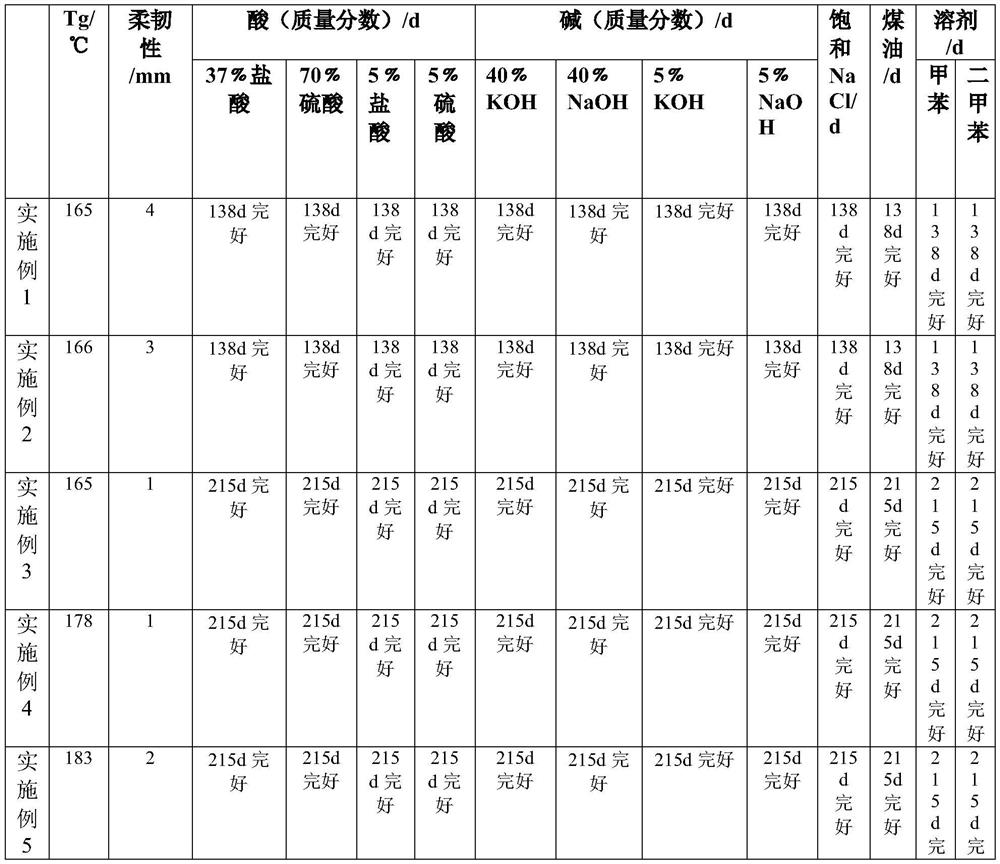

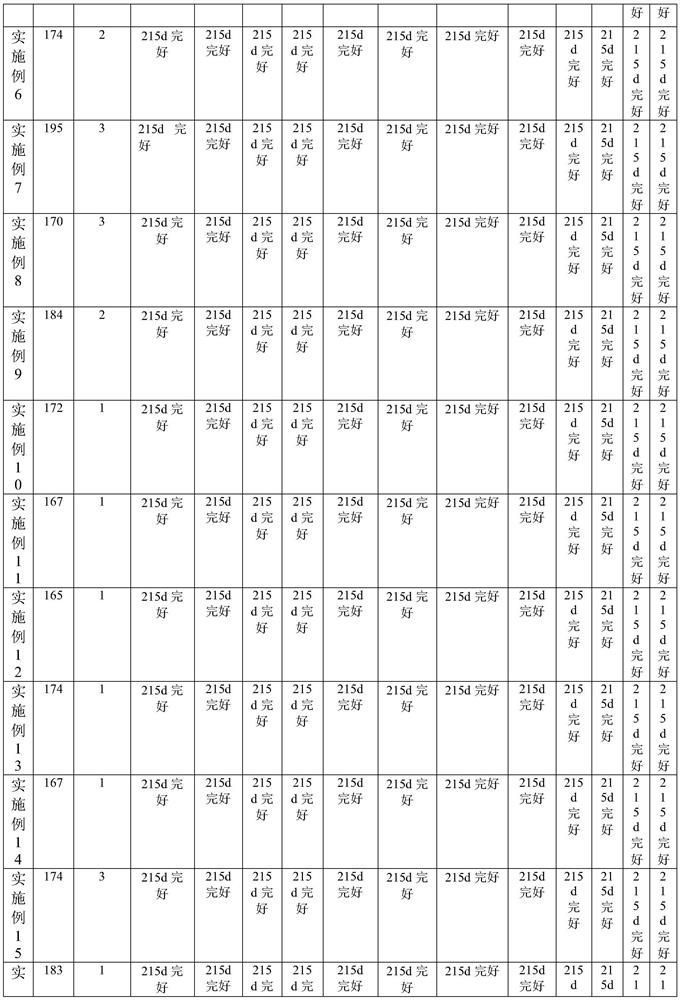

Embodiment 1-16

[0030] The preparation method of waterborne polyurea coating material is as follows:

[0031] (1) Add oily isocyanate and tributyl phosphate and / or triphenyl phosphate respectively to the dispersing tank according to the following formula table, and stir for 10 minutes;

[0032] (2) Add different contents of carbon black, bentonite, titanium dioxide and other pigments and fillers to the above slurry, and use 1000-2000r to disperse for 1-2 hours until the slurry is stable;

[0033] (3) Add different contents of wetting agent, leveling agent and defoamer to the stable slurry in sequence, stir for 10 minutes, and filter to obtain component A.

[0034] (4) Dissolve potassium silicate in deionized water until it becomes clear and transparent, and filter to obtain component B. The mass ratio of potassium silicate to deionized water is 4:6.

[0035] (5) Mix component A and component B obtained above at a mass ratio of 1.5:1, react at 0-30°C, and solidify to form a film.

[0036] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com