Corrosion and scale inhibition control method of circulating cooling water system and corrosion and scale inhibitor

A technology of circulating cooling water and corrosion and scale inhibitors, applied in chemical instruments and methods, descaling and water softening, natural water treatment, etc., can solve the problems of increasing the difficulty of sterilization control, poor impact resistance, accelerated corrosion, etc., to achieve Scale and corrosion inhibition performance Environmentally friendly, excellent scale and corrosion inhibition performance, and the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

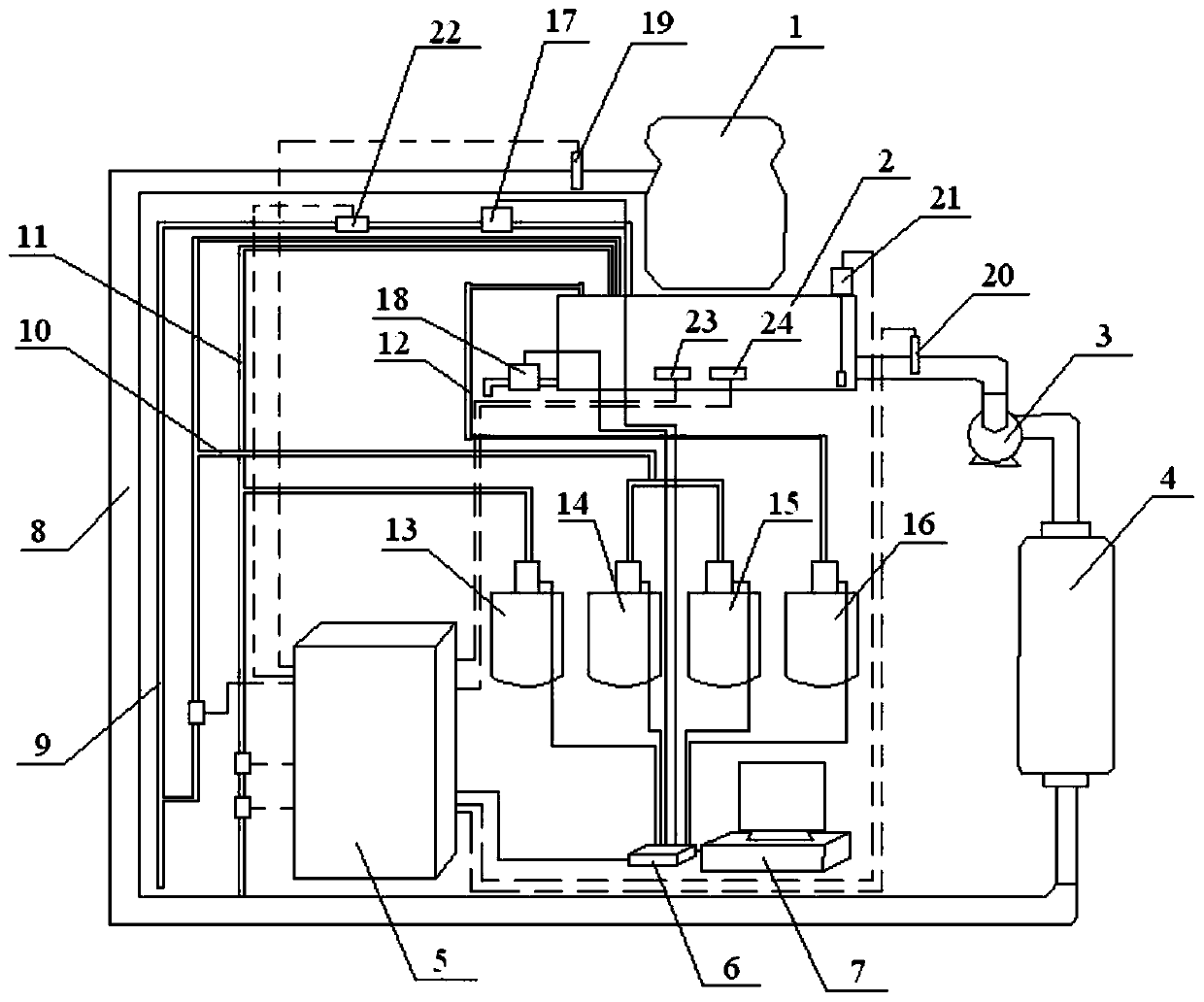

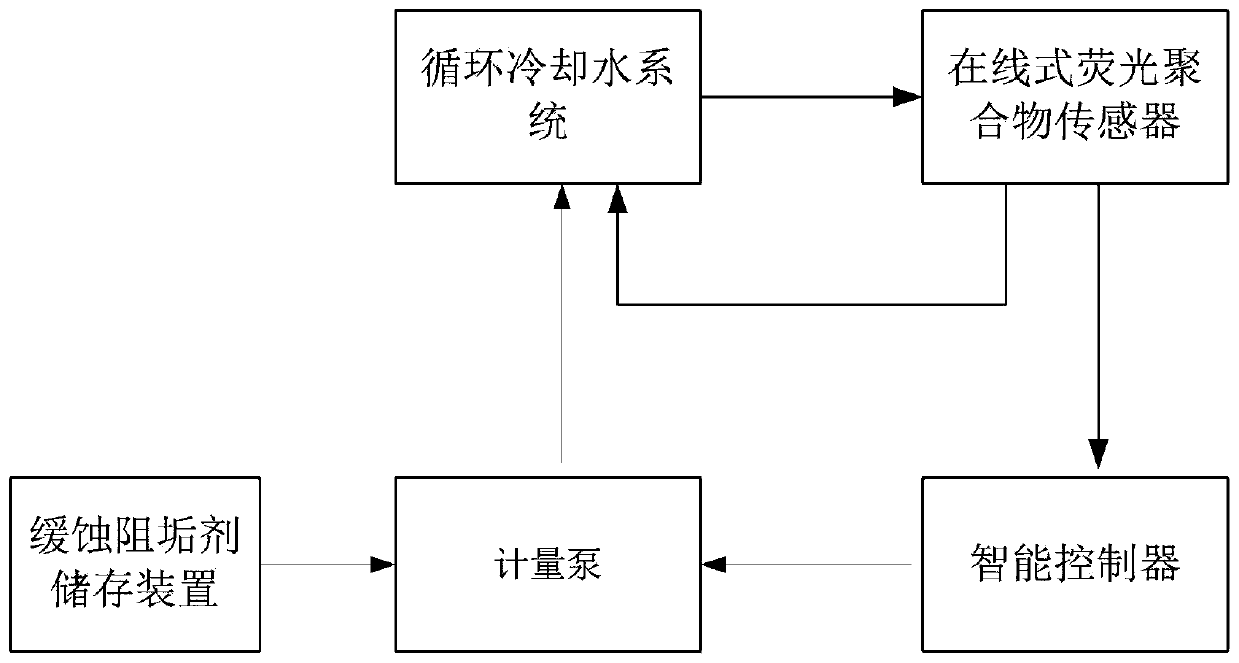

Method used

Image

Examples

Embodiment 1

[0049] In this example, the concentration of the pH stabilizer added is 150 g / ton of water, the pH value of the control system is 8.0, and the corrosion and scale inhibitor includes the following raw materials by weight: 2-phosphonobutane-1,2, 15% of 4-tricarboxylic acid, 10% of fluorescent polymer, 3% of sodium molybdate, 1% of phenylpropyltriazole, and the balance is water.

[0050] In this example, the water quality of the supplementary water

[0051] project index Ca 2+ (in CaCO 3 meter, mg / l)

17.28 Total hardness (in CaCO 3 meter, mg / l)

33.70 Total alkalinity (as CaCO 3 meter, mg / l)

57.50 Cl - (mg / l)

17.11 pH 6.82 Conductivity (us / cm) 101

[0052] Refer to "Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotary Coupling Method GB / T 18175-2014" for corrosion rate determination

[0053] Test number Test piece material Corrosion rate, mm / a 1 A3 carbon ste...

Embodiment 2

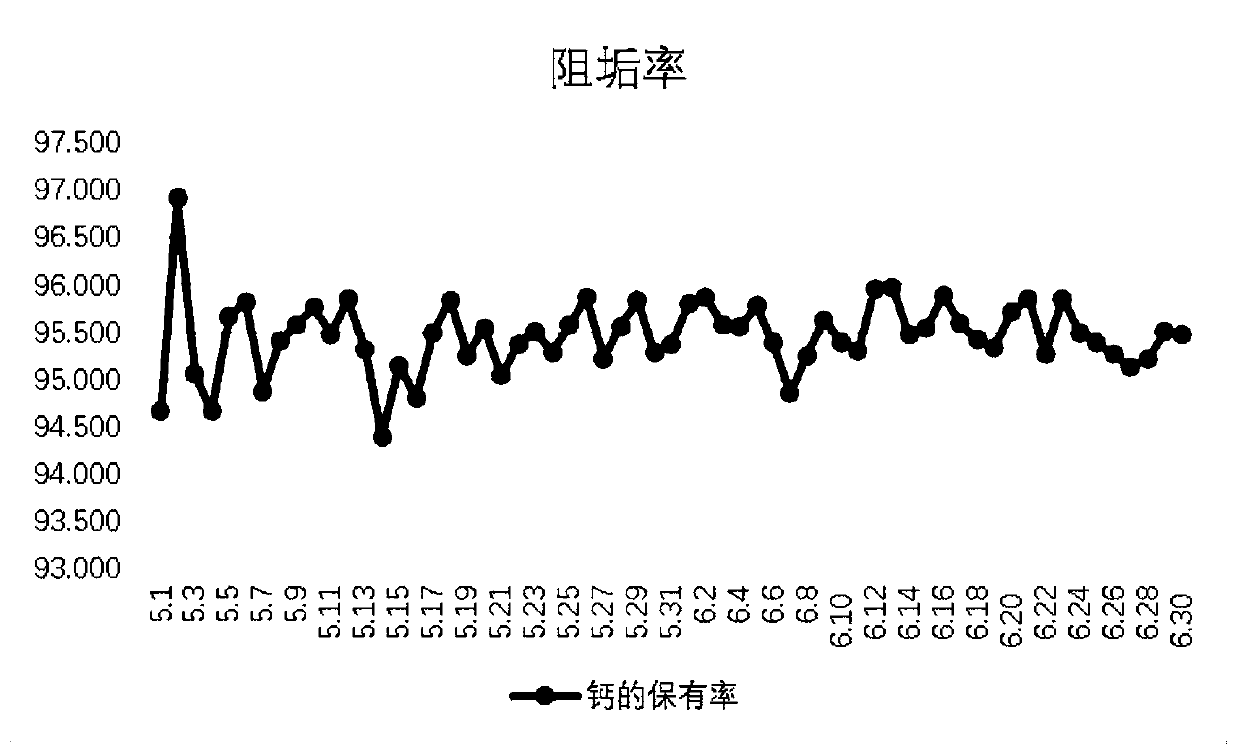

[0057] This embodiment relates to the evaluation of the application effect of the method of the present invention in an industrial circulating cooling water system.

[0058] The power circulating water system of a glycine production enterprise, the circulating water volume is 6000m 3 / h, holding water volume 3000m 3 , the temperature difference is 6 °C, the recovered steam condensate is all used for the supplementary water of the circulating cooling water system, and the quality of the steam condensate is

[0059] project index Ca 2+ (in CaCO 3 meter, mg / l)

7.32 Total hardness (in CaCO 3 meter, mg / l)

9.50 Total alkalinity (as CaCO 3 meter, mg / l)

68.36 Cl - (mg / l)

3.21 pH 7.12 Conductivity (us / cm) 81

[0060] In this example, the concentration of the pH stabilizer added is 200 g / ton of water, the pH value of the control system is between 7.8 and 8.0, and the pH value stabilizer adopts an automatic dosing dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com