Composite liquid-cooling heat pipe radiator

A technology of heat pipe radiator and composite liquid, which is applied in the field of heat transfer, can solve the problems of poor fit, poor fit of the plane of the tubular heat pipe and the heating element, easy occurrence of local hot spots, and the heat dissipation effect of the combined heat pipe. The effect of heat dissipation, strengthening the structural strength, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

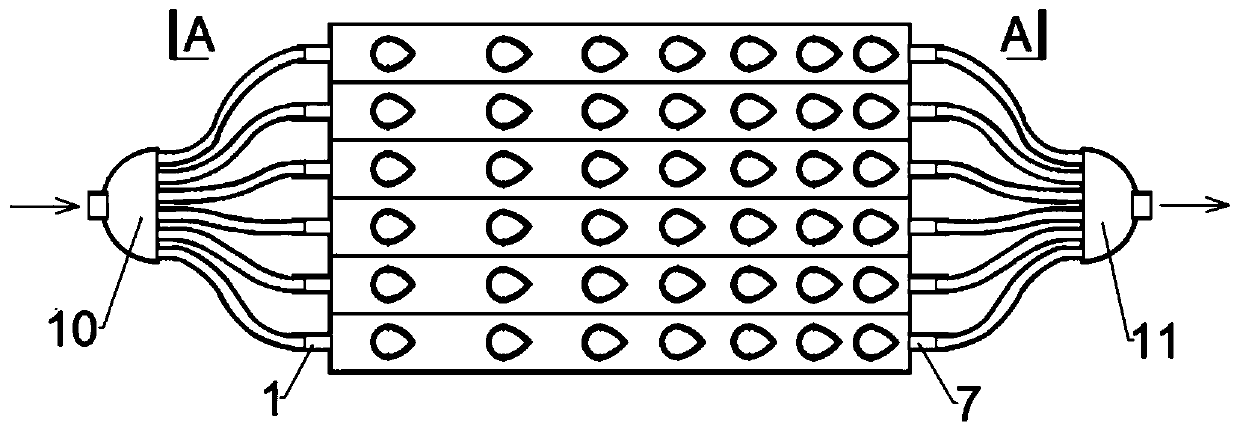

[0038] Such as Figure 1-6As shown, a composite liquid-cooled heat pipe radiator in this embodiment includes a flat heat pipe 3, and the heat generated by the heating element 4 is transferred to the bottom plate of the flat heat pipe 3. The protrusions form the tubular heat pipe 9 , and the inner cavity of the flat heat pipe 3 communicates with the inner cavity of the tubular heat pipe 9 . It also includes a shell 2, the flat heat pipe 3 and the tubular heat pipe 9 are both located in the shell 2, and the bottom plate of the flat heat pipe 3 is sealed and attached to the bottom surface of the shell 2. The housing 2 is provided with a coolant inlet 1 and a coolant outlet 7 . The area surrounded by the outer surface of the flat heat pipe 3 , the outer surface of the tubular heat pipe 9 and the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com