Quick-charging type lithium ion battery

A technology for lithium-ion batteries and battery shells, which is applied to battery electrodes, secondary batteries, battery pack components, etc. It can solve problems such as unfavorable high-rate charging and discharging, increased polarization in the battery, and poor cycle performance. Fast charging performance, reduced concentration polarization, and the effect of reducing the transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

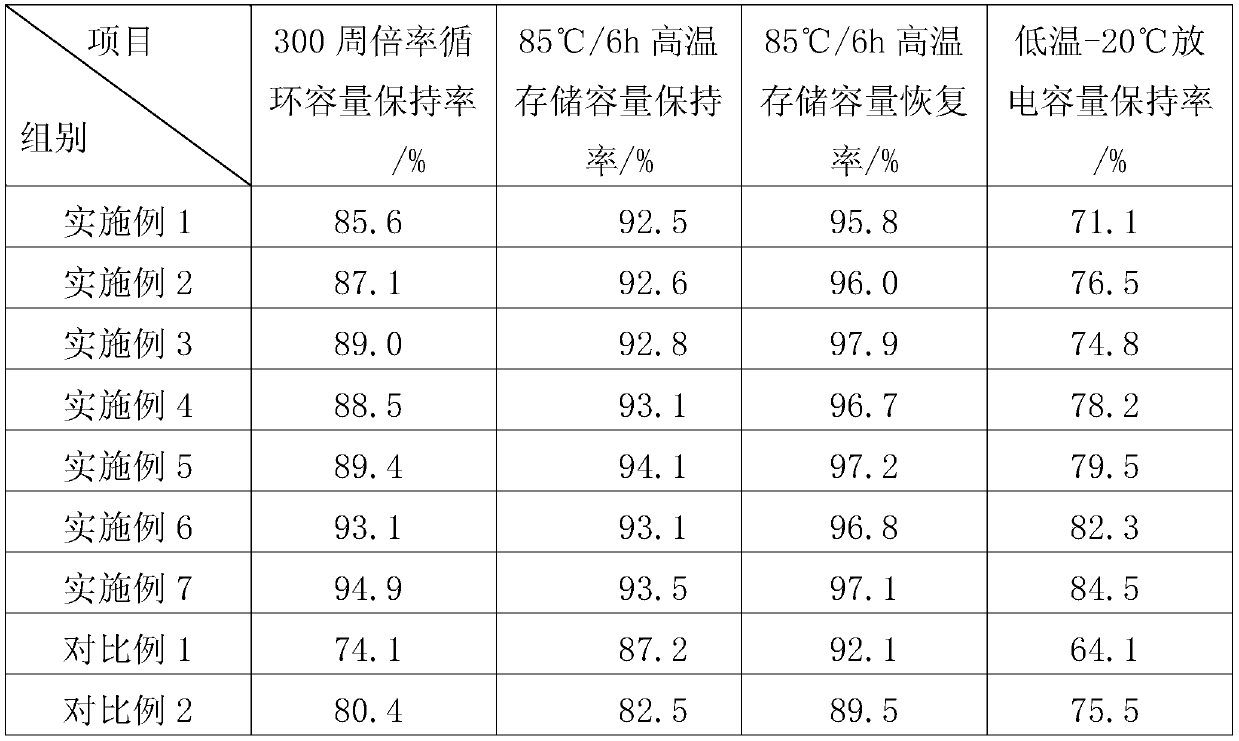

Examples

Embodiment 1

[0021] Add polyvinylidene fluoride to N-methyl-pyrrolidone, stir quickly and evenly, then add acetylene black to the above solution, stir evenly, then add lithium cobaltate and stir evenly to form a positive electrode slurry, and finally coat the positive electrode slurry Covered on aluminum foil, baked, rolled, cut into pieces, and welded to get the positive pole piece. Among them, the surface density and compaction of the positive electrode sheet are 12 mg / cm 2 and 3.6g / cm 3 . For the negative electrode, mix secondary carbon microbeads, acetylene black, carboxymethyl cellulose, and styrene-butadiene rubber and stir evenly. Finally, the dispersed slurry is coated on the copper foil, which is baked, rolled, and cut into pieces. After welding, a negative pole piece is obtained. Among them, the surface density and compaction of the negative electrode sheet are 6 mg / cm 2 and 1.5g / cm 3 .

[0022] Electrolyte solution preparation: In a high-purity helium-protected glove box, ...

Embodiment 2

[0025] Add polyvinylidene fluoride to N-methyl-pyrrolidone, stir quickly and evenly, then add acetylene black to the above solution, stir evenly, then add lithium cobaltate and stir evenly to form a positive electrode slurry, and finally coat the positive electrode slurry Covered on aluminum foil, baked, rolled, cut into pieces, and welded to get the positive pole piece. Among them, the areal density and compaction of the positive electrode sheet are 11 mg / cm 2 and 3.6g / cm 3 . For the negative electrode, mix secondary carbon microbeads, acetylene black, carboxymethyl cellulose, and styrene-butadiene rubber and stir evenly. Finally, the dispersed slurry is coated on the copper foil, which is baked, rolled, and cut into pieces. After welding, a negative pole piece is obtained. Among them, the surface density and compaction of the negative electrode sheet are 6 mg / cm 2 and 1.5g / cm 3 .

[0026] Electrolyte solution preparation: In a high-purity helium-protected glove box, 20...

Embodiment 3

[0029] Add polyvinylidene fluoride to N-methyl-pyrrolidone, stir quickly and evenly, then add acetylene black to the above solution, stir evenly, then add lithium cobaltate and stir evenly to form a positive electrode slurry, and finally coat the positive electrode slurry Covered on aluminum foil, baked, rolled, cut into pieces, and welded to get the positive pole piece. Among them, the surface density and compaction of the positive electrode sheet are 12 mg / cm 2 and 3.6g / cm 3. For the negative electrode, mix secondary carbon microbeads, acetylene black, carboxymethyl cellulose, and styrene-butadiene rubber and stir evenly. Finally, the dispersed slurry is coated on the copper foil, which is baked, rolled, and cut into pieces. After welding, a negative pole piece is obtained. Among them, the surface density and compaction of the negative electrode sheet are 5 mg / cm 2 and 1.5g / cm 3 .

[0030] Electrolyte solution preparation: In a high-purity helium-protected glove box, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com