R-T-B series permanent magnet material as well as preparation method and application thereof

A R-T-B, permanent magnet material technology, applied in magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem of excessive dependence on the performance improvement of sintered NdFeB magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

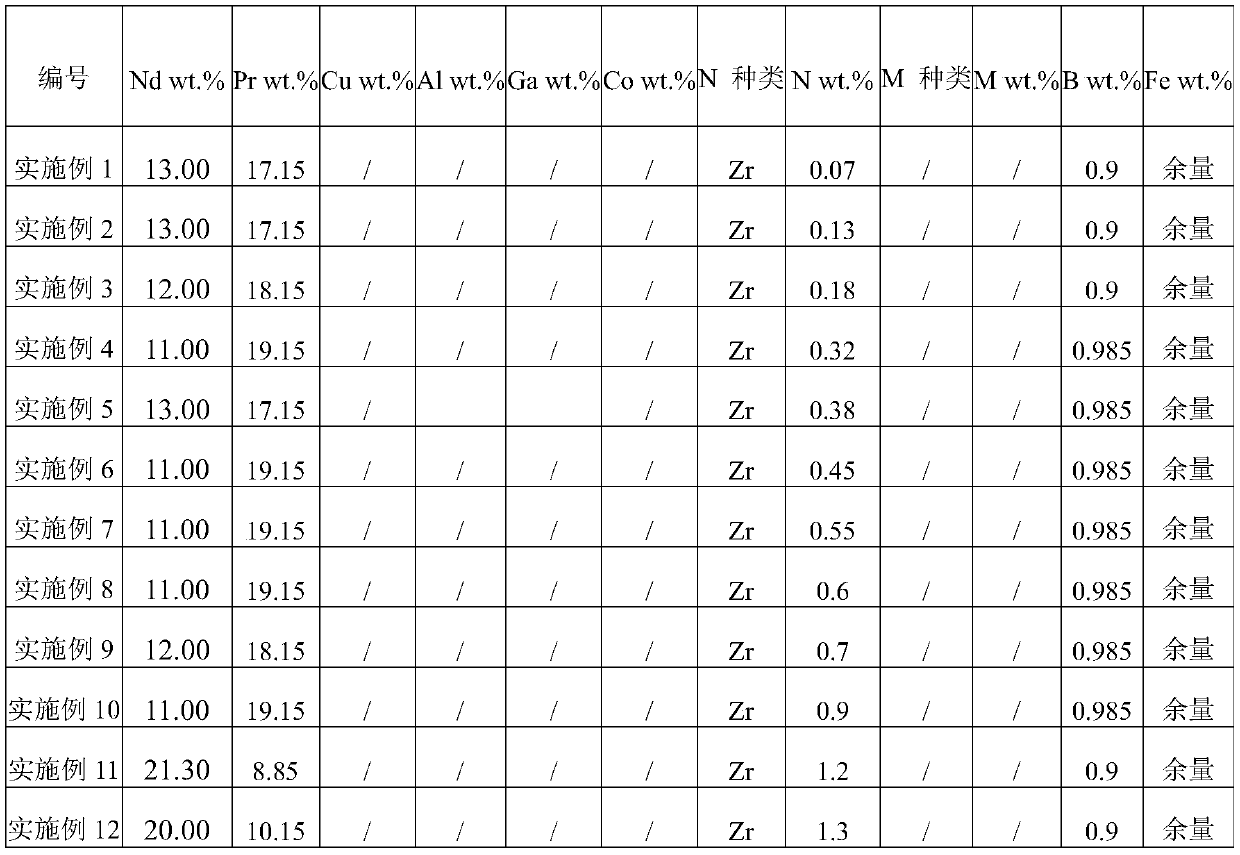

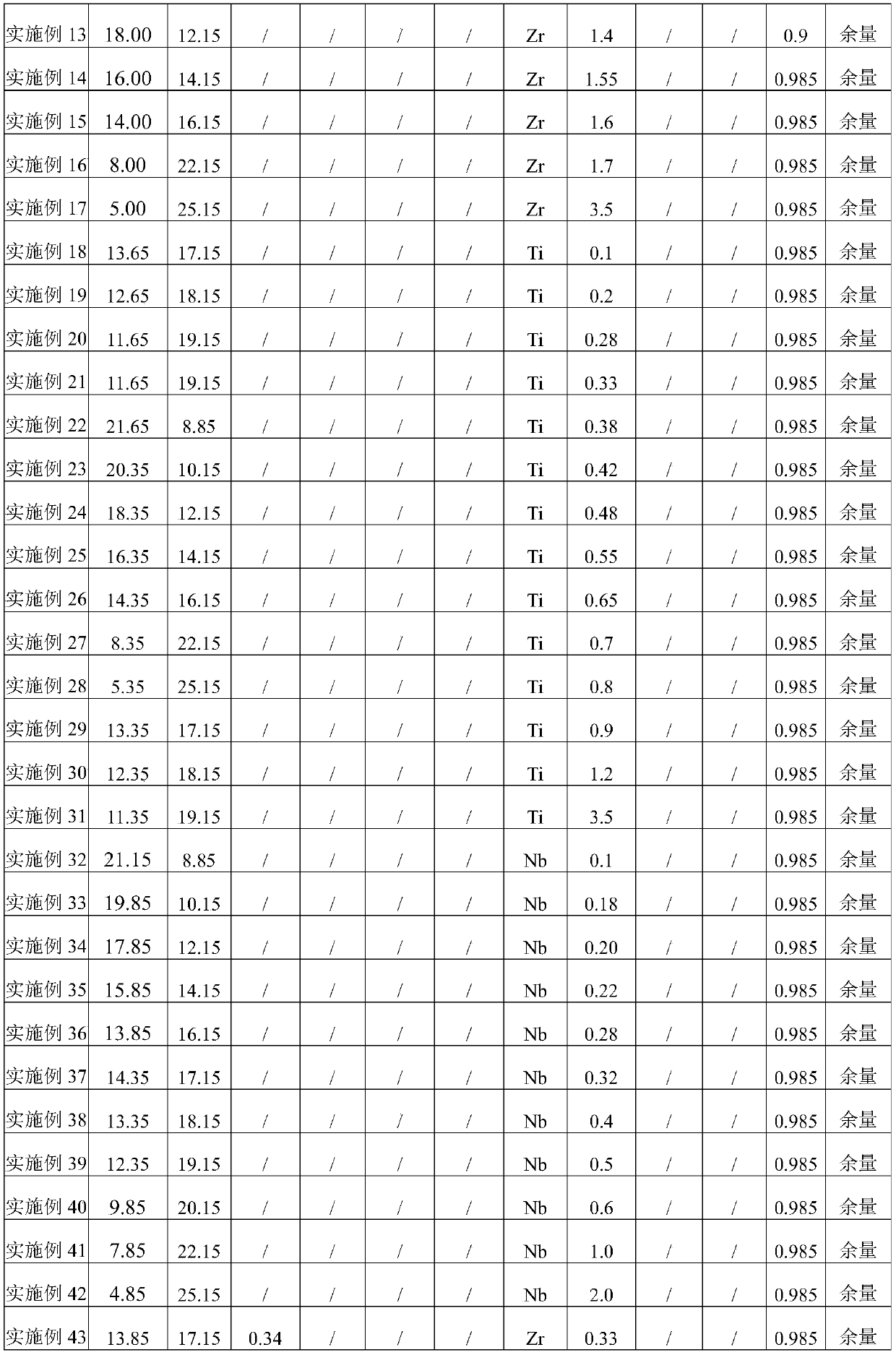

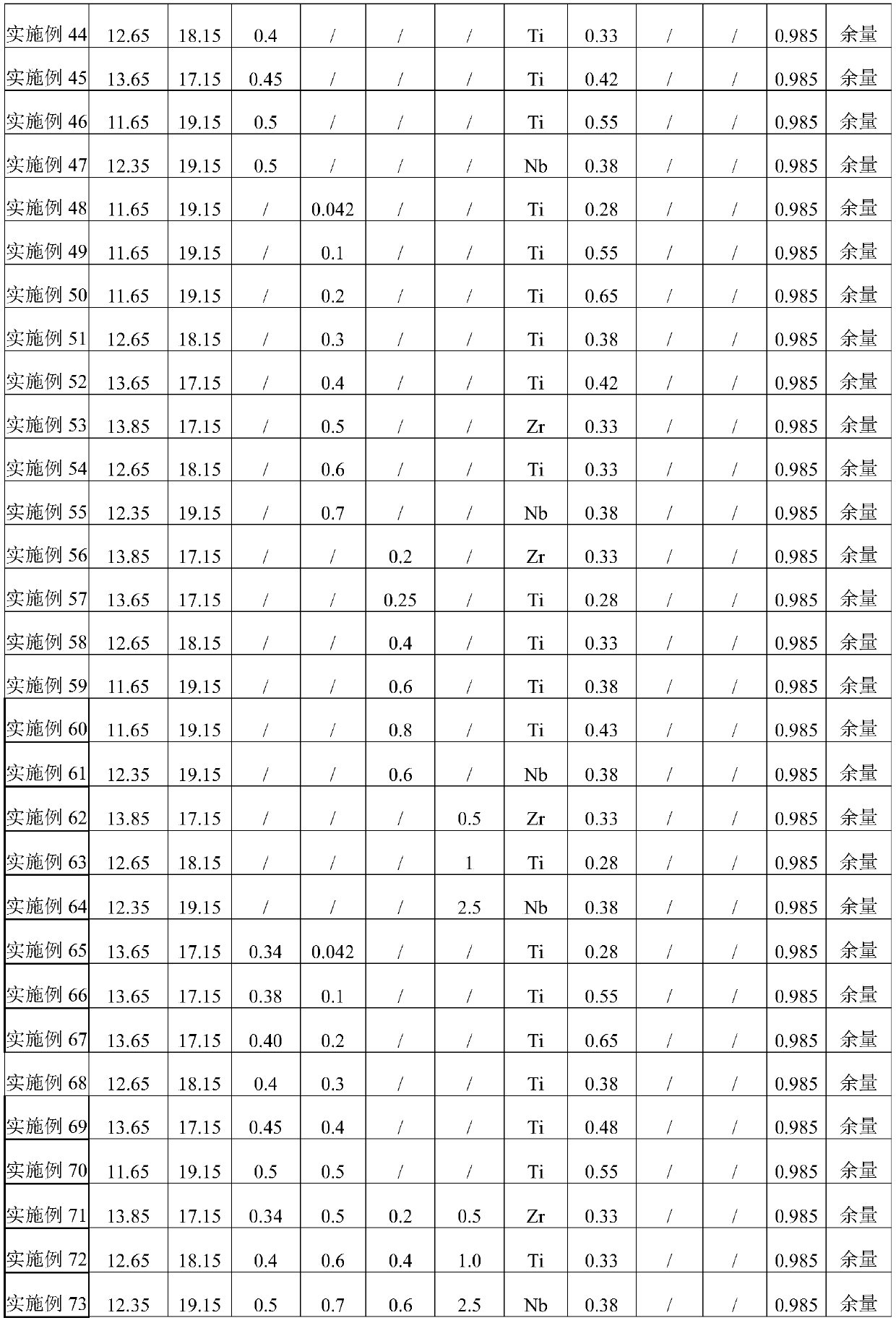

Examples

Embodiment 1

[0145] The preparation method of R-T-B series sintered magnet is as follows:

[0146] (1) Melting process: according to the formula shown in Table 1, take the prepared raw materials and put them into a crucible made of alumina, and put them in a high-frequency vacuum induction melting furnace at 5×10 -2 Vacuum melting is carried out at a temperature below 1500°C in a vacuum of Pa.

[0147] (2) Casting process: after vacuum smelting, Ar gas is passed into the smelting furnace to make the air pressure reach 55,000 Pa, and then casting is carried out at 10 2 ℃ / sec-10 4 °C / sec cooling rate to obtain quenched alloy.

[0148] (3) Hydrogen crushing process: Vacuumize the hydrogen crushing furnace where the quenched alloy is placed at room temperature, and then pass hydrogen gas with a purity of 99.9% into the hydrogen crushing furnace to maintain the hydrogen pressure at 0.15 MPa. After fully absorbing hydrogen, Heat up while evacuating to fully dehydrogenate, then cool, and take ...

Embodiment 2- Embodiment 88、 comparative example 1-3

[0155] The raw materials were prepared according to the formula shown in Table 1, and the other process conditions were the same as in Example 1 to obtain the R-T-B series sintered magnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com