Combined cooling, heating and power micro gas turbine device

A micro gas turbine, combined cooling, heating and power supply technology, applied in gas turbine installations, mechanical equipment, combustion equipment, etc., can solve the problems of large space, large volume, waste of manpower, etc., and achieve compact structure, small volume, and long shaft. minimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

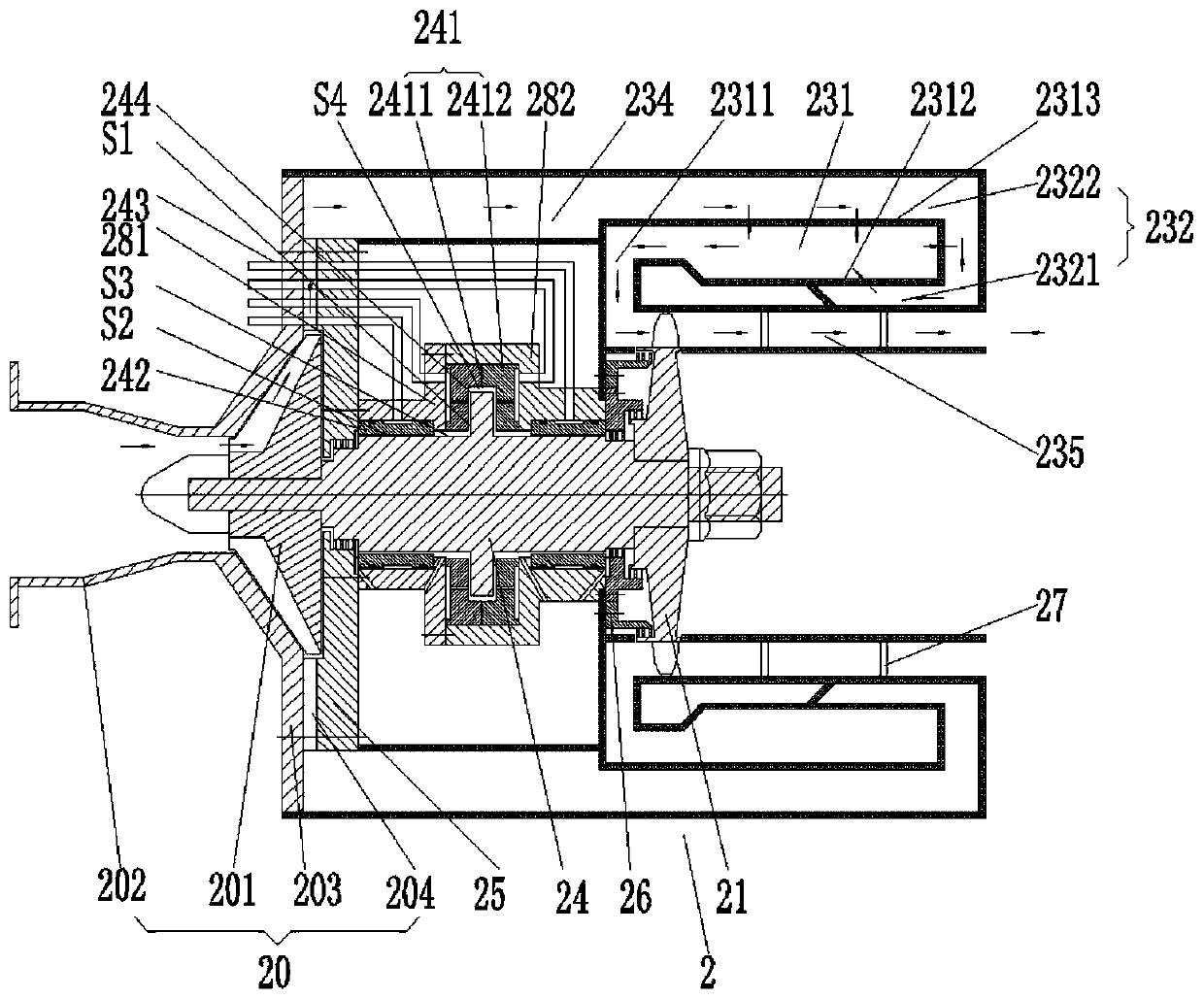

[0100] For this example see figure 1 A thrust disc is set in the middle of the rotating shaft 24 of the micro gas turbine 2, and a thrust bearing 241 is sleeved on the thrust disc; two ends of the rotating shaft 24 are respectively sleeved with radial bearings 242.

[0101] Thrust bearing 241: installed on the rotating shaft 24, including a symmetrically arranged first bearing body 2411 and a second bearing body 2412, the first bearing body 2411 and the second bearing body 2412 are installed symmetrically with the thrust plate in the axial direction and have a predetermined The first axial gap S1; the outer end walls of the first bearing body 2411 and the second bearing body 2412 are respectively provided with a first air groove and a second air groove, and the bottoms of the first air groove and the second air groove are provided with transparent air holes. The air hole communicates with each air groove and the corresponding first axial gap S1; the third radial gap S3 is pres...

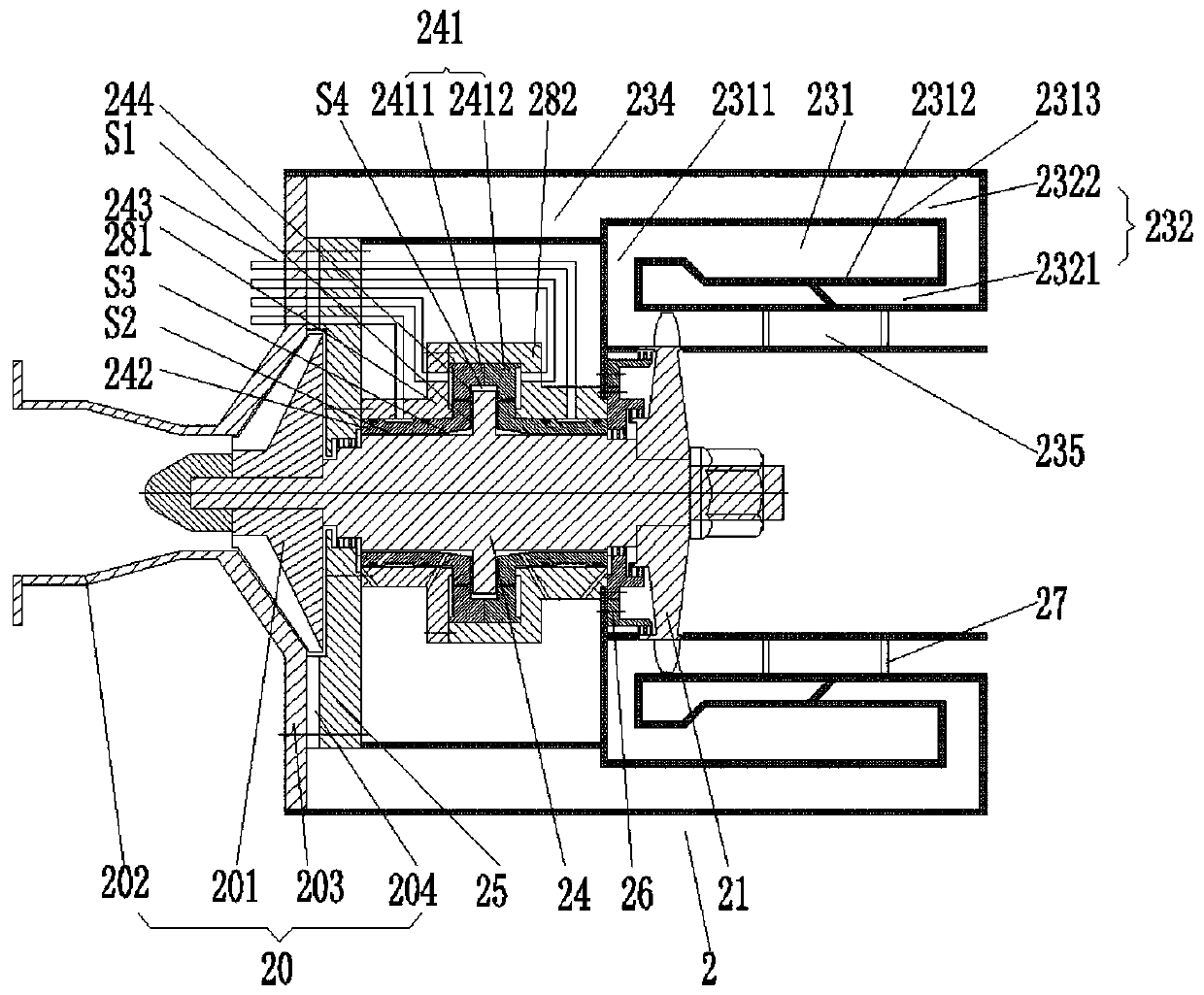

Embodiment 2

[0108] For this example see figure 2 , On the basis of Embodiment 1, the thrust bearing 241 close to the shaft surface and the radial bearing 242 close to the thrust disk end surface are connected as one; the third radial gap S3 is a tapered gap and shrinks toward the radial bearing 242.

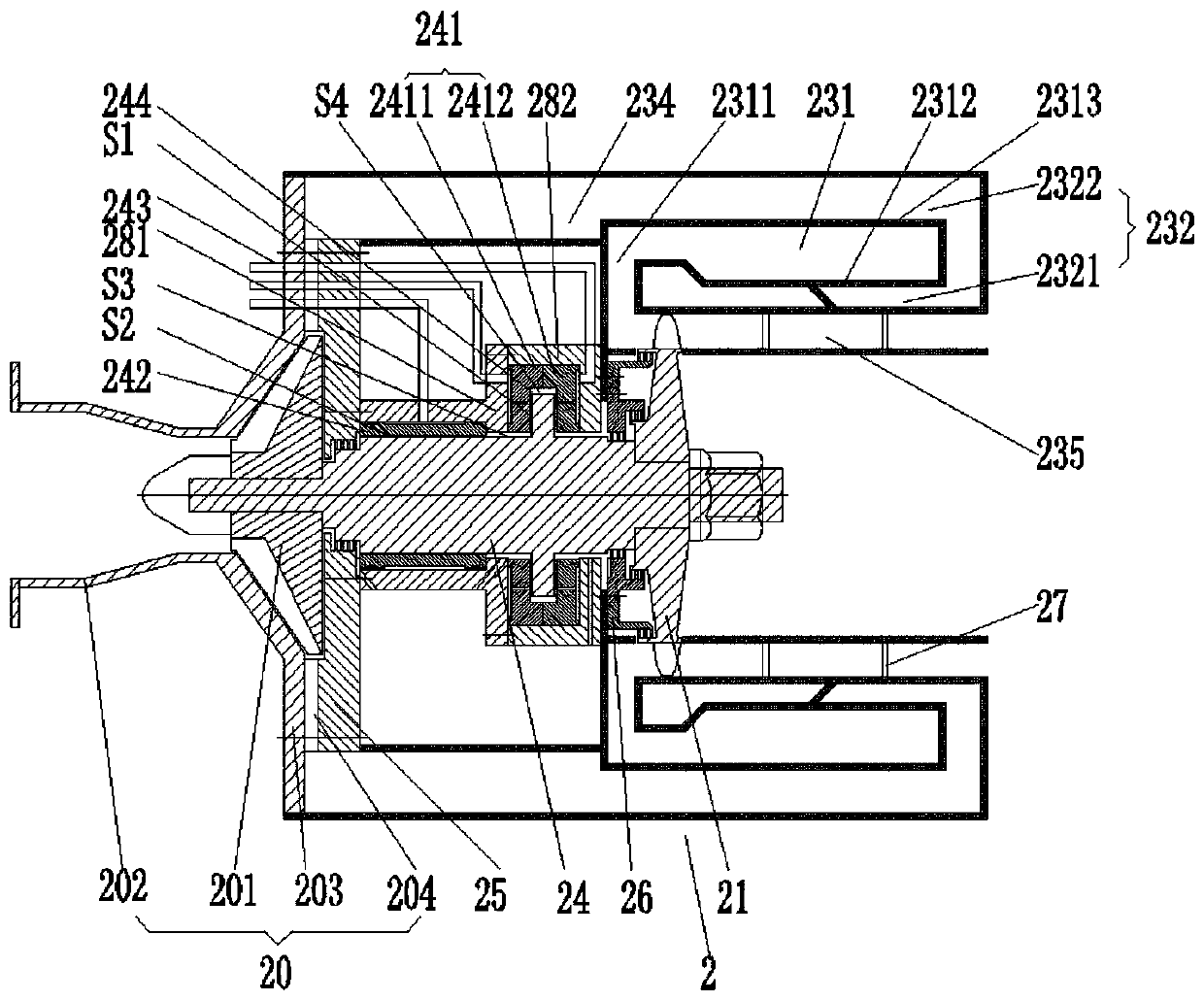

Embodiment 3

[0110] For this example see image 3 , the rotating shaft 24 of the micro gas turbine 2 is provided with a thrust disc at one end of the turbine 21, and a thrust bearing 241 is sleeved on the thrust disc;

[0111] Thrust bearing 241: installed on the rotating shaft 24, including the first bearing body 2411 and the second bearing body 2412, the first bearing body 2411 and the second bearing body 2412 are installed symmetrically with the thrust plate in the axial direction and have a predetermined first axis To the gap S1; the outer end walls of the first bearing body 2411 and the second bearing body 2412 are respectively provided with a first air groove and a second air groove, and the bottoms of the first air groove and the second air groove are provided with transparent air holes, and the air holes communicate with each other. The air groove and the corresponding first axial gap S1; the preset third radial gap S3 between the inner ring of the first bearing body 2411 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com