Prefabricated assembly type concrete anti-floating inspection well and machining method thereof

A prefabricated assembly and prefabricated well technology, applied in the direction of manufacturing tools, artificial islands, protection devices, etc., can solve the problems of uneven settlement of prefabricated concrete inspection wells, reduced driving comfort, and reduced urban road flatness, etc. The effect of uneven settlement, increased flatness and driving comfort, and ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

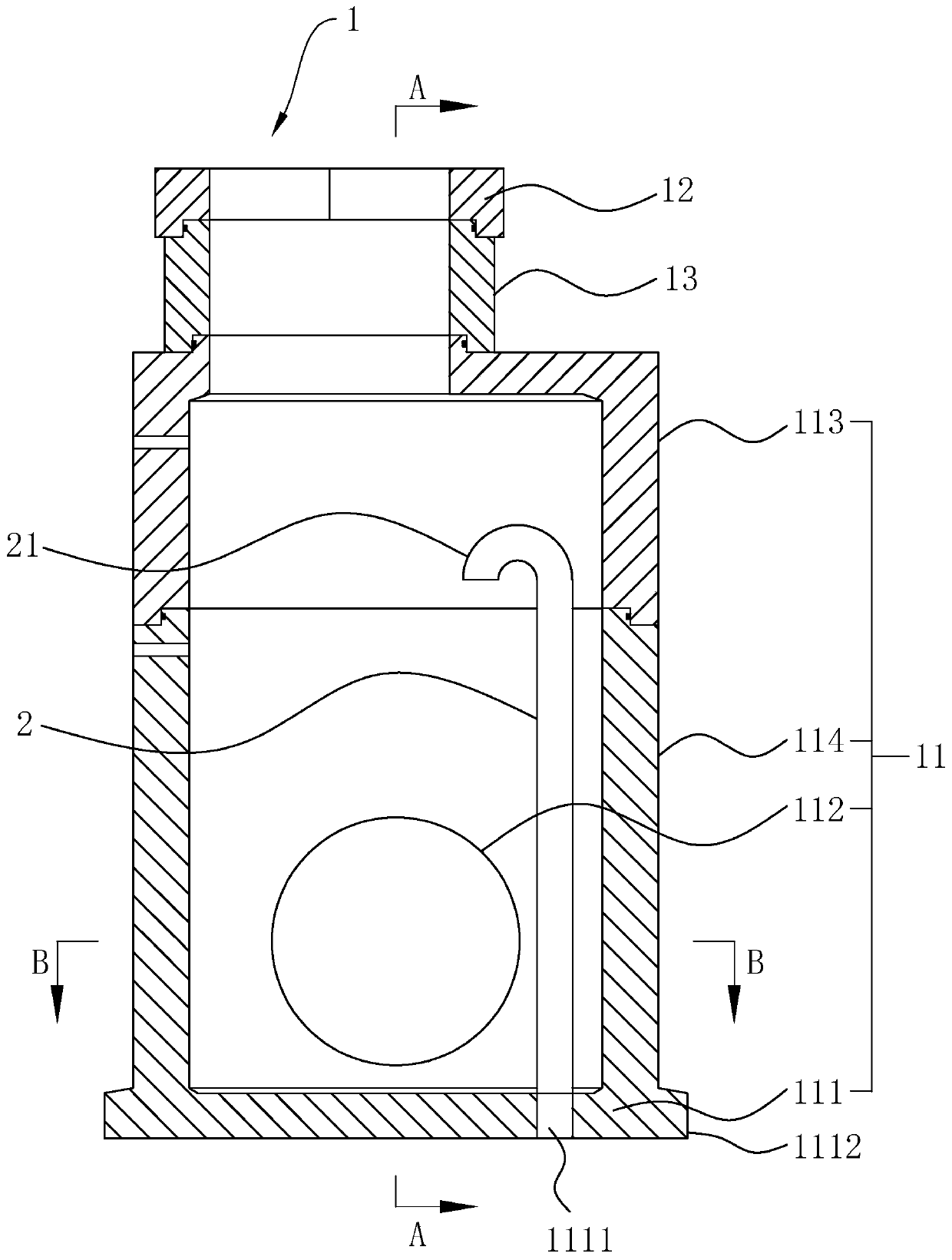

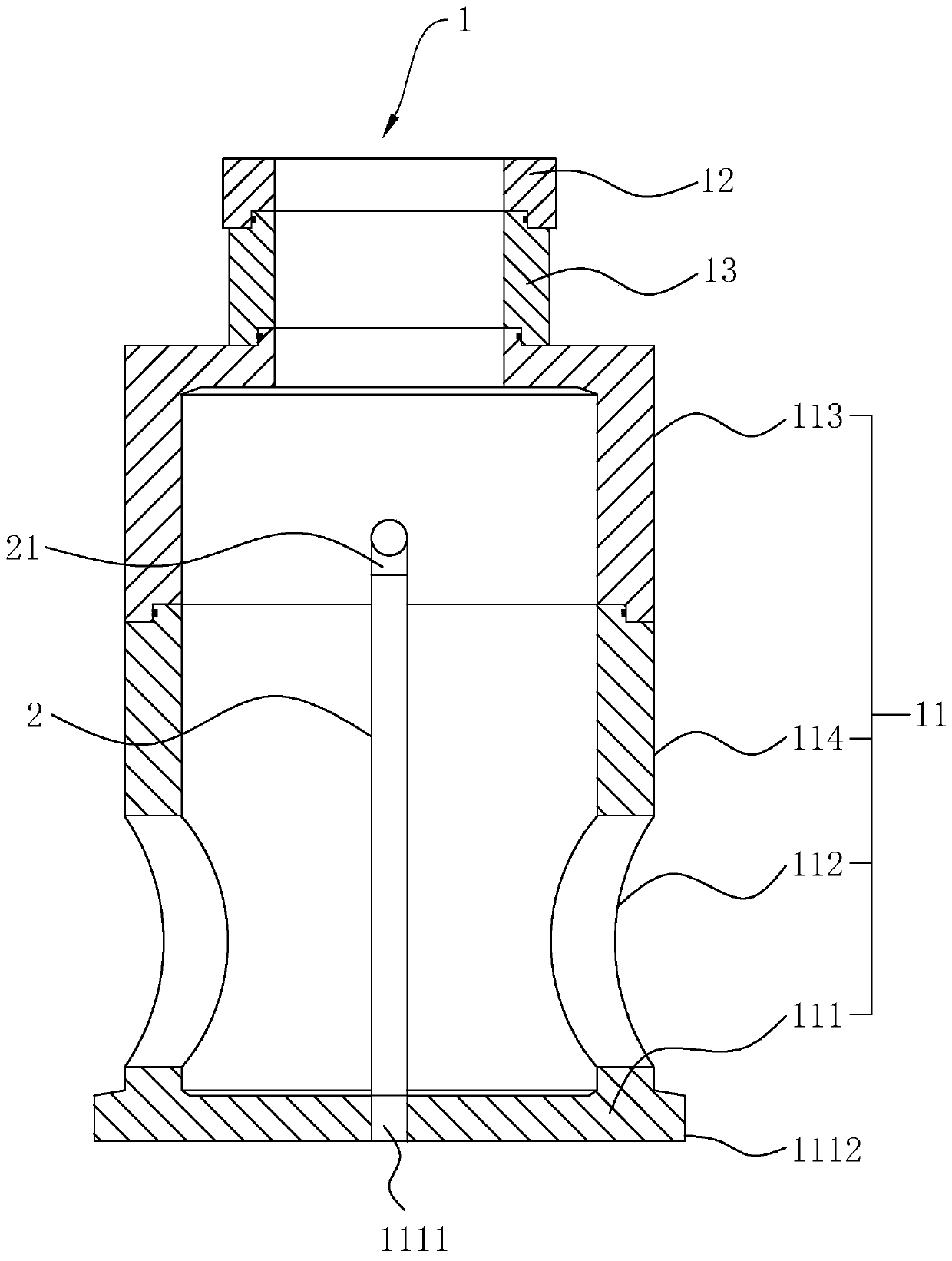

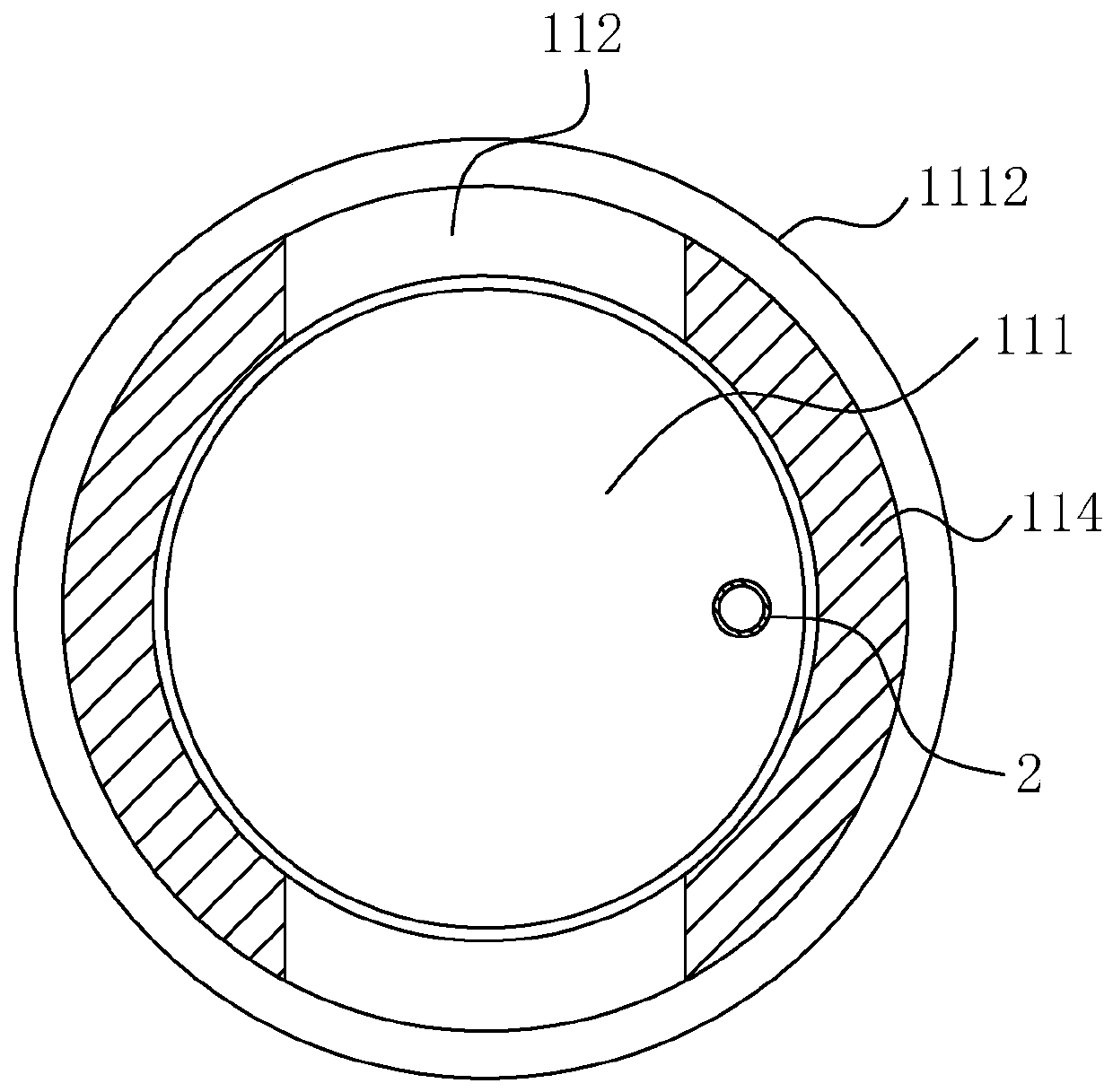

[0046] refer to figure 1 and figure 2 , the present invention discloses a prefabricated assembled concrete anti-floating inspection well, which includes a prefabricated inspection well body 1, the prefabricated inspection well body 1 includes a prefabricated well chamber 11, and a prefabricated well chamber for introducing groundwater into the prefabricated well chamber 11 is fixed inside Discharging to reduce the anti-floating mechanism that the rise of the groundwater level produces jacking force on the prefabricated well chamber 11. When the groundwater level rises and exceeds the safe water level, the groundwater exceeding the safe water level can enter the prefabricated well chamber 11 through the anti-floating mechanism and be discharged through the prefabricated well chamber 11, which can effectively reduce the impact of the groundwater level rise on the prefabricated inspection well body 1 The generated jacking force avoids the uneven settlement of the prefabricated ...

Embodiment 2

[0053] refer to Figure 5 and Figure 6 The difference between this embodiment and Embodiment 1 is that the prefabricated well chamber 11 also includes a well chamber adjustment block 115, and the upper end and the lower end of the well chamber adjustment block 115 are respectively sealed and connected with the lower end of the upper well chamber 113 and the upper end of the lower well chamber 114. The upper and lower ends of the middle well chamber adjustment block 115 are integrally formed with tongue-and-groove connection structures, which are respectively connected and fixed with the corresponding well chambers in a tongue-and-groove connection, and wedge-shaped rubber rings are also installed at each connection to improve the connection. The sealing effect ensures the anti-leakage performance. The height of the prefabricated well chamber 11 can be adjusted through the well chamber adjustment block 115, so that it can be applied to construction sites with different depths,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com