Bidirectional nut locking device and combined roller

A two-way lock and nut technology, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of unstable assembly pressure and complicated disassembly operation of roll shafts, so as to improve working capacity, high combined connection strength, and prevent cracking Transverse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

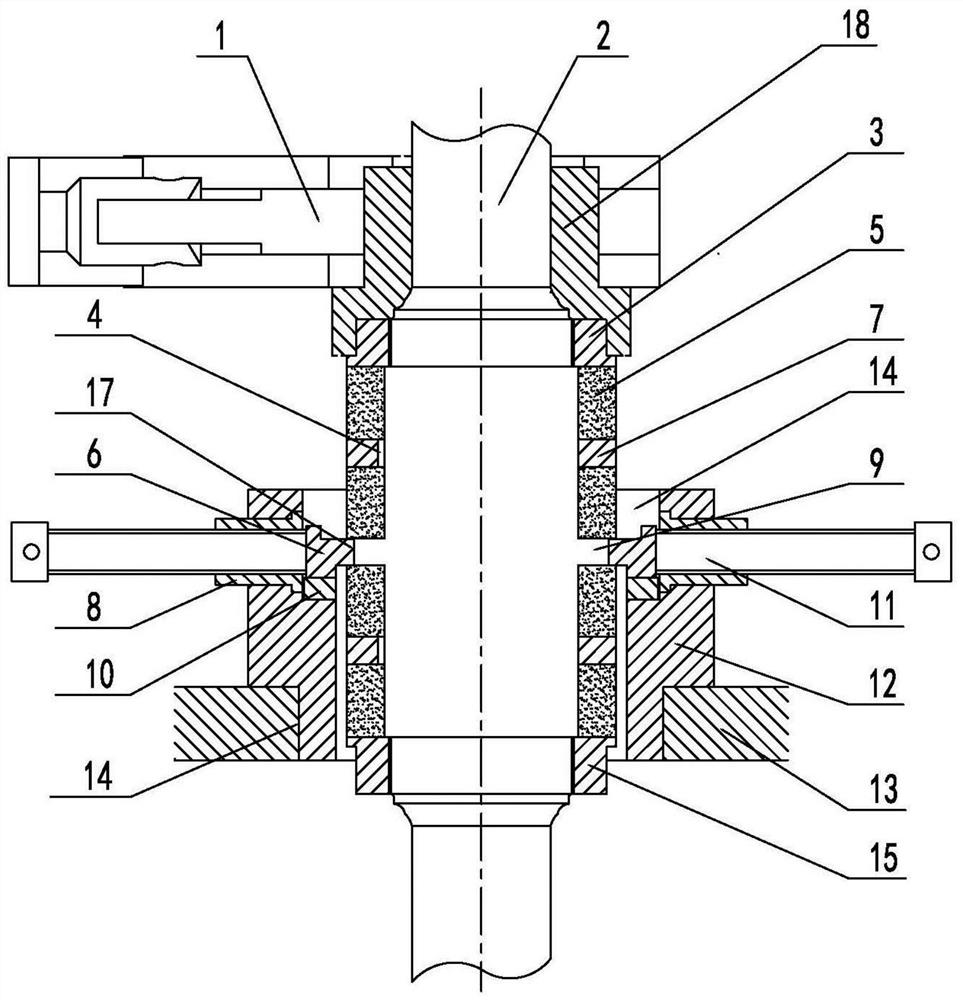

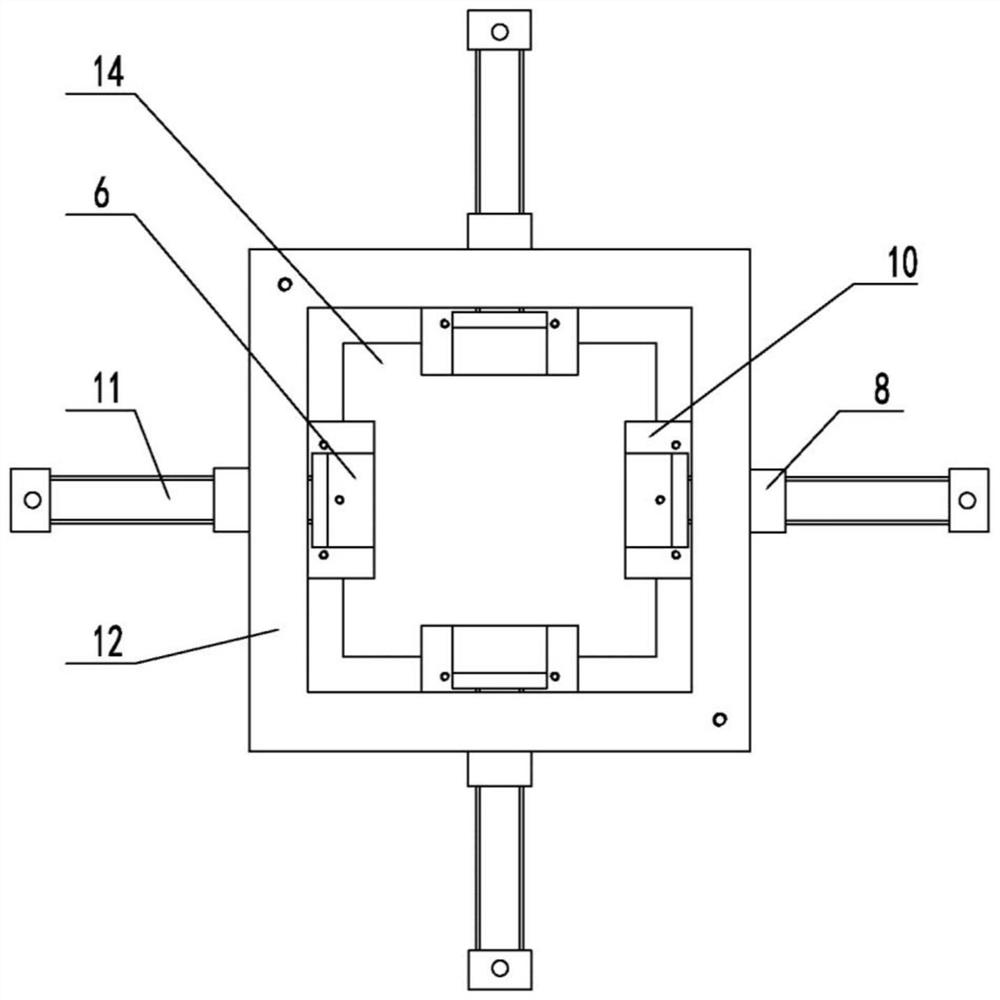

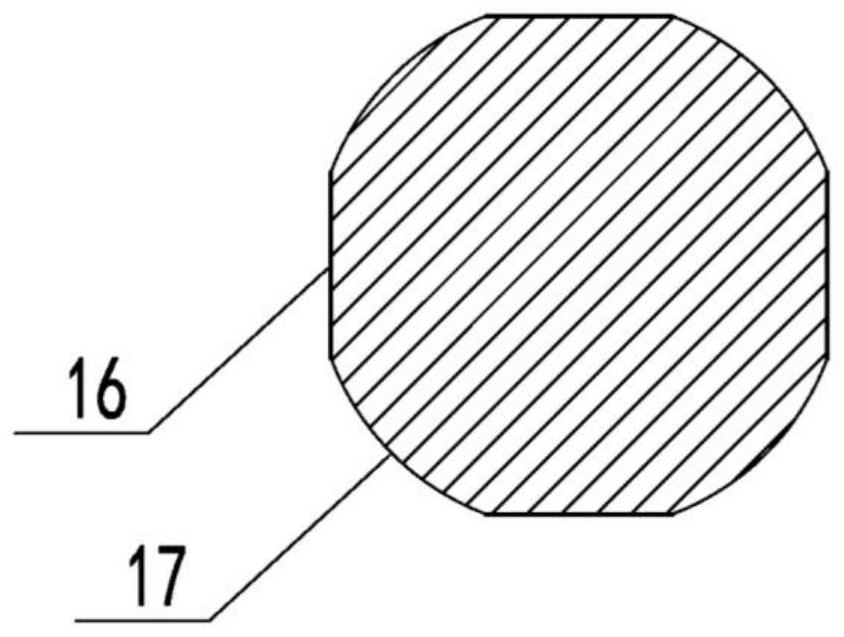

[0036] figure 1 is a schematic diagram of the nut two-way locking device; figure 2 is the top view of the nut two-way locking device, figure 2 The drive mechanism and shoulders are not shown. like figure 1 , figure 2 As shown, the nut two-way locking device (hereinafter referred to as the locking device) provided in this embodiment is used to clamp the accessory on the shaft. The locking device includes a shaft shoulder 9, a lock nut, a driving mechanism and a fixing mechanism . Wherein, the shaft shoulder 9 is arranged in the middle of the shaft, and the two ends of the shaft are respectively provided with external threads suitable for lock nuts, and a lock nut is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com