Planar spiral microphone array

A microphone array and helical technology, applied in the field of microphone arrays, can solve the problems of affecting detection accuracy, large position error of array elements, and easy change of effective aperture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

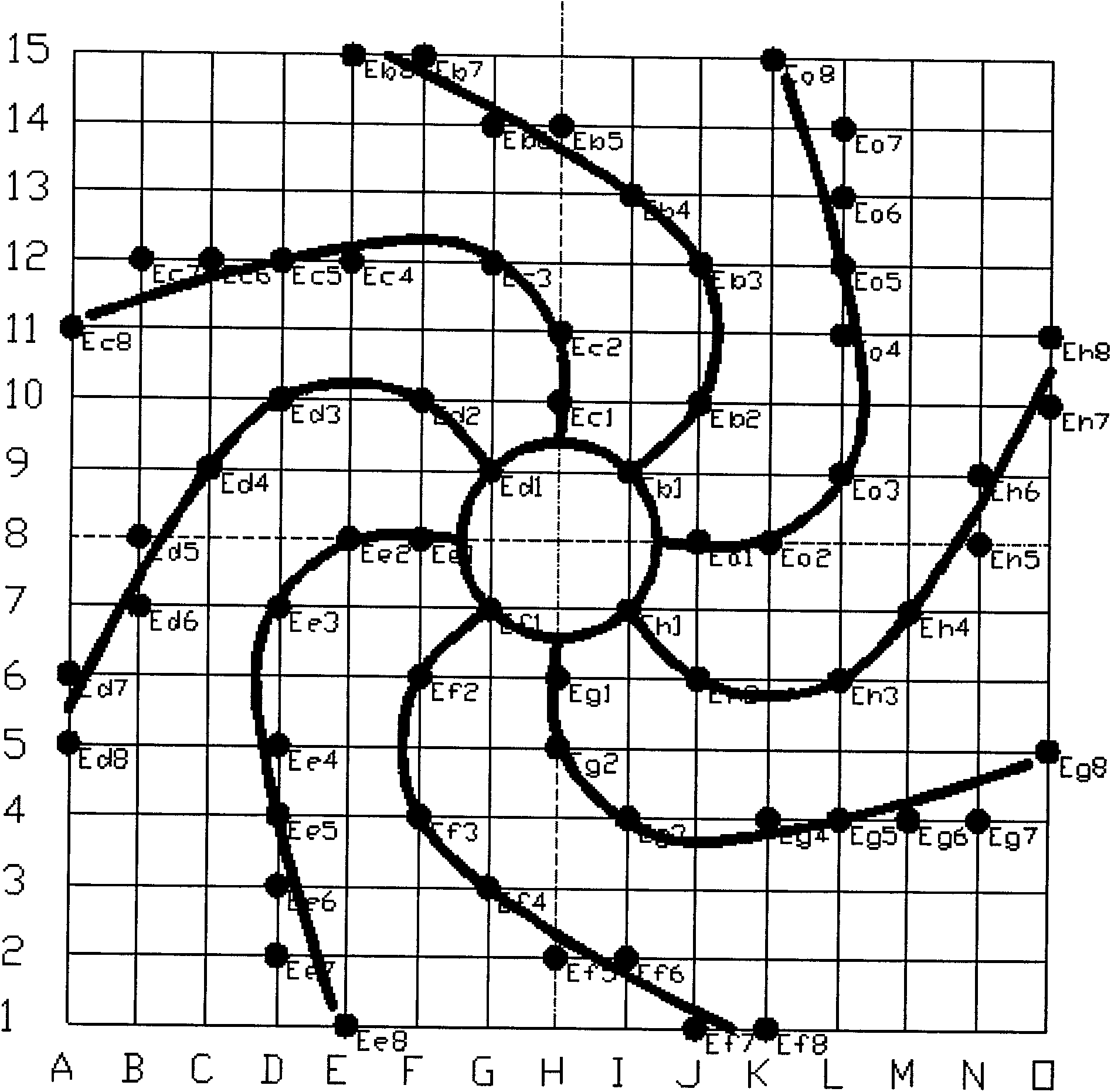

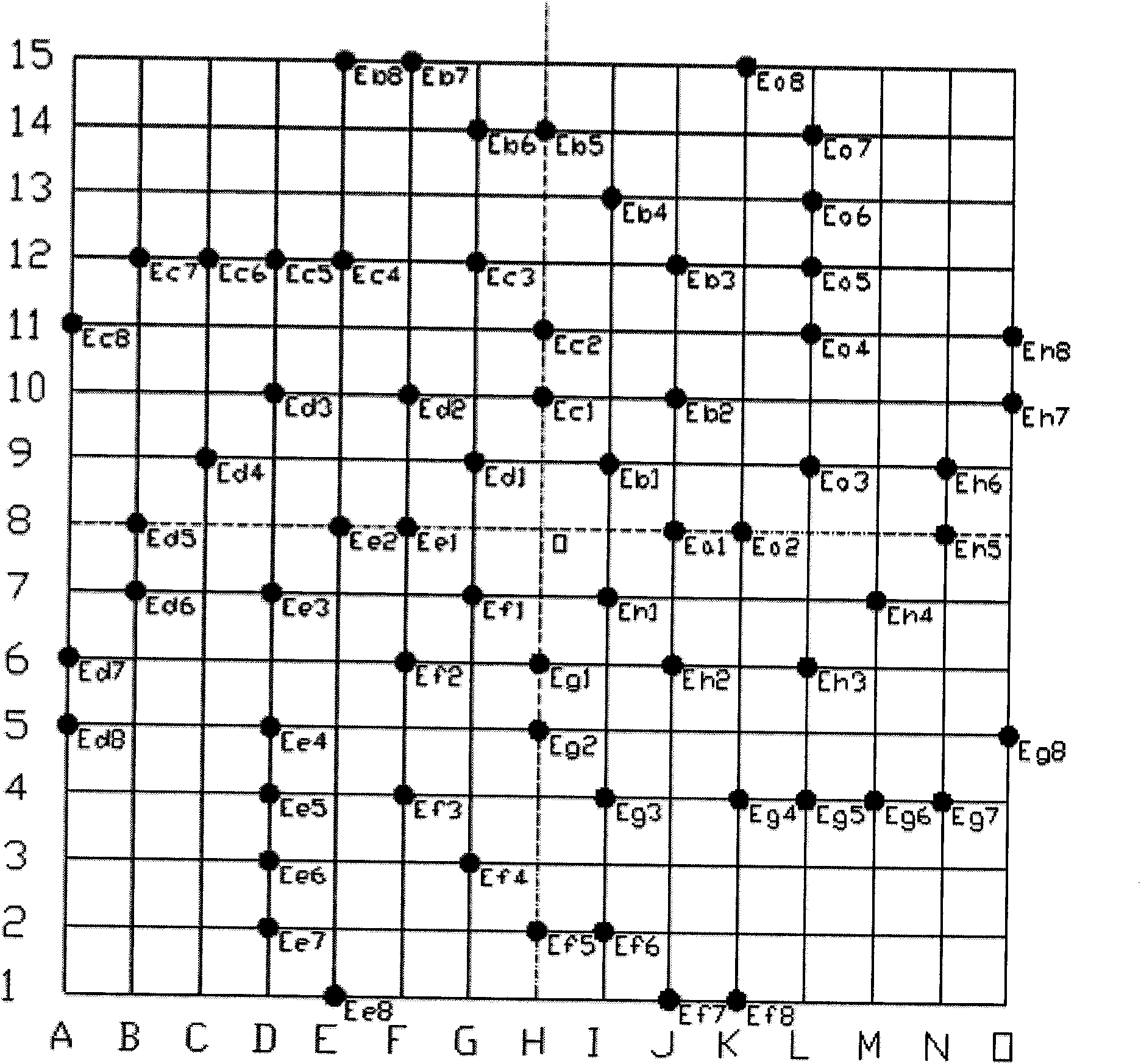

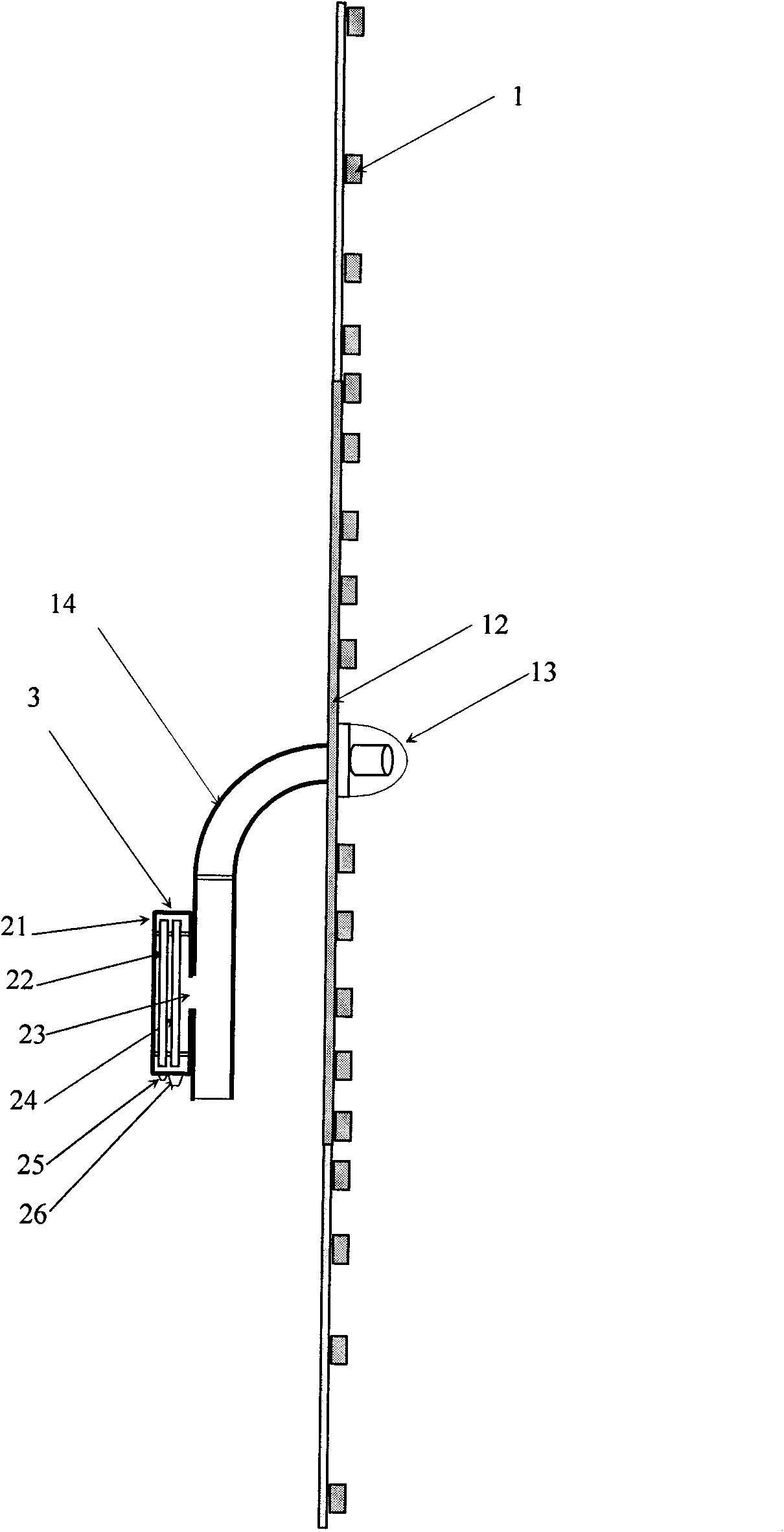

[0068] Such as Figure 10-13 As shown, this embodiment provides a planar spiral microphone array composed of a square array main part and four array folding parts. The planar helical microphone array of this embodiment includes the main components such as the rigid spokes of the planar helical array, a support rod, a microphone, a camera, and a signal acquisition and processing instrument.

[0069] In this embodiment, a microphone installation hole is designed at each array element position, and the installation hole is fixedly connected to the preamplifier through the array element installation insulating sheath, and the design of this mounting seat facilitates the installation of the microphone.

[0070] In order to cooperate with the planar spiral microphone array of this embodiment for data collection, a corresponding hub box and a signal conditioning and collection instrument box are also designed. The signal lines of each array element (that is, the microphone) are inde...

Embodiment 2

[0079] This embodiment is basically the same as Embodiment 1, the difference is that the structural form of the array body part 12 and the array folding part 11 of this embodiment is simpler, in the shape of a circle and a spiral, such as Figure 14 and 15 shown. This structure changes the number of spokes of the planar helical microphone array, but the distribution position relationship of the array element sensors is exactly the same as that of Embodiment 1, that is, the array element coordinates remain unchanged.

Embodiment 3

[0081] Such as Figure 16 As shown, the planar helical rigid support has a total of 64 nodes, and all nodes are distributed at a special coordinate. These nodes are located at selected nodes in the intersection of 21 lines evenly spaced horizontally and 21 lines evenly spaced vertically, and the selected nodes are distributed on 8 spirals with 8 array elements on each spiral. Its normalized coordinates are shown in Table 4.

[0082] Table 4 (Spiral Array Coordinates of Array Elements Distributed on 21×21 Intersection Nodes)

[0083] Element label

[0084] Element label

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com