Silicon carbide single crystal, substrate and preparation method thereof

A silicon carbide single crystal and crystal growth technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the axial temperature gradient drop, difficult to achieve the radial temperature gradient of silicon carbide single crystal, change, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

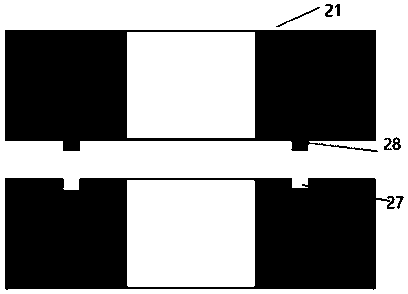

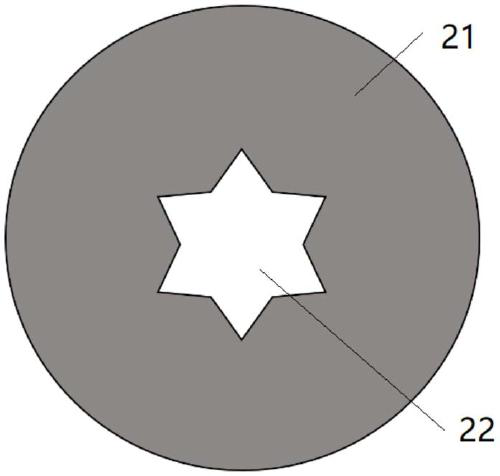

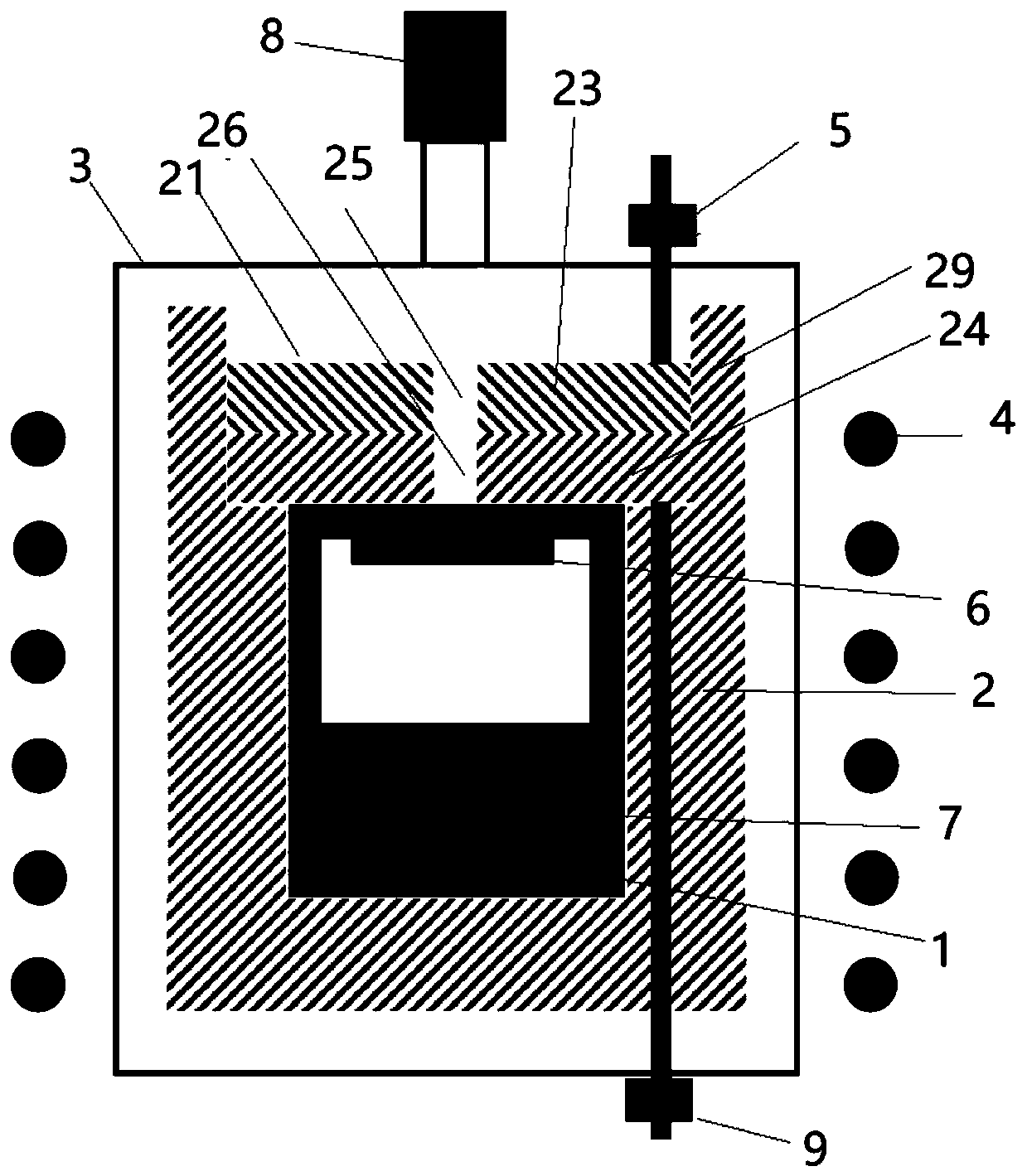

[0077] refer to figure 1 , the crystal growth device, which includes a crucible 1, an insulating layer 2, a furnace body 3 and a heating element 4, the insulating layer 2 includes an upper insulating layer group 21 above the crucible 1, and the upper insulating layer group 21 is provided with a temperature measuring hole 22, and the upper insulating layer group 21 is provided with a temperature measuring hole 22. The insulation layer group 21 comprises the first upper insulation layer 23 and the second upper insulation layer 24 of the common central axis, the first upper insulation layer 23 is provided with the first opening 25, the second upper insulation layer 24 is provided with the second opening 26, and the temperature measuring hole 22 make the crucible 1 form a low-temperature zone for holding the raw material 7 and a high-temperature zone for setting the seed crystal 6; it also includes a rotation adjustment mechanism 5, and the rotation adjustment mechanism rotates the...

Embodiment 2

[0088] The crystal growth device also includes a lifting adjustment mechanism 9; the lifting adjustment structure includes a second motor, a lifting rod and a second connector, and the second connector is connected with the first upper insulation layer 23 and / or the second upper insulation layer 24, and the second Connect the motor to drive the first upper insulation layer 23 and / or the second upper insulation layer 24 to lift along the common central axis through the lifting rod and the second connector; the insulation layer 2 includes the side insulation layer 2, the height of the lifting of the upper insulation layer group Not higher than the height of the side insulation layer 2. The crystal growth device can adjust the radial temperature gradient in the growth chamber for growing single crystals; while reducing the radial temperature gradient, it can also ensure a certain axial temperature gradient, and can efficiently produce high-quality, low-defect single crystal.

[...

Embodiment 3

[0093] refer to Figure 4 , as an embodiment, the crystal growth device includes a crucible 1, a heating coil group and a heat preservation structure, the crucible 1 forms a growth chamber, and the growth chamber includes a raw material 7 area containing a raw material 7 and a crystal growth area where a seed crystal 6 is set, and the heating The coil set is arranged around the side wall of the crucible 1, and the heating coil set includes a first coil set corresponding to the height of the raw material 7 area and a second coil set corresponding to the height of the crystal growth area, along the path from the raw material 7 to the seed crystal 6 direction, the inner diameter of the second coil group increases. The coil diameter is increased from the raw material 7 upwards, thereby reducing the temperature at the seed crystal 6. Compared with the previous coil design with a constant diameter, the axial temperature gradient in the growth chamber is increased. However, for the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com