Oil field two-stage dehydration system and method

A technology of oil field and dehydration equipment, which is applied in the directions of chemical dehydration/demulsification, mechanical dehydration/demulsification, dehydration/demulsification adjustment/control, etc., which can solve labor-intensive, heavy workload, machine loss, etc. problems, to achieve the effect of high degree of automation, accurate results and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

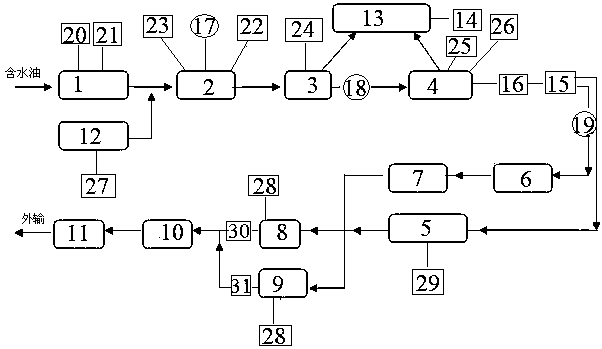

[0041]This embodiment provides a two-stage dehydration treatment system in an oil field, which includes a control cabinet and a two-stage dehydration device. The two-stage dehydration device includes a temperature sensor 20, a liquid level gauge, a pressure sensor and an electric control. The temperature sensor 20, The liquid level gauge, the pressure sensor and the electric control are all electrically connected to the control cabinet. The control cabinet includes an alarm module. Controls include motorized valves and pumps.

[0042] The present invention can improve the automation of the production process of the two-stage dehydration station through the cooperative control of each sensor and the control cabinet, realize unattended transformation, save human resources, and reduce the labor intensity of employees.

Embodiment 2

[0044] On the basis of Embodiment 1, this embodiment provides a two-stage dehydration treatment system in an oil field, the two-stage dehydration device includes a ball collecting cylinder 1, a first heating furnace 2, a buffer tank 3, and a third A phase separator 4, a tundish, an external delivery pump and a second heating furnace 10, a dosing device 12 is connected through a pipeline between the ball receiving cylinder 1 and the first heating furnace 2, and the inlet of the first heating furnace 2 A pump one 17 is arranged on the water pipeline, a pump two 18 is arranged between the buffer tank 3 and the three-phase separator 4, a pump three 19 is arranged between the three-phase separator 4 and the intermediate tank, and a pump three 19 is arranged between the three-phase separator 4 and the intermediate tank. 17. Pump two 18 and pump three 19 are electrically connected to the control cabinet.

[0045] Control the start and stop of pump one 17 through the control cabinet t...

Embodiment 3

[0047] On the basis of Embodiment 1, this embodiment provides a two-stage dehydration treatment system in an oil field, the two-stage dehydration device includes a ball collecting cylinder 1, a first heating furnace 2, a buffer tank 3, and a third A phase separator 4, a tundish, an external delivery pump and a second heating furnace 10, a dosing device 12 is connected through a pipeline between the ball receiving cylinder 1 and the first heating furnace 2, and the inlet of the first heating furnace 2 A pump one 17 is arranged on the water pipeline, a pump two 18 is arranged between the buffer tank 3 and the three-phase separator 4, a pump three 19 is arranged between the three-phase separator 4 and the intermediate tank, and a pump three 19 is arranged between the three-phase separator 4 and the intermediate tank. 17. Pump two 18 and pump three 19 are electrically connected to the control cabinet.

[0048] The ball collecting cylinder 1 is provided with a temperature sensor 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com