Alcohol-friction-resistant ultra-fine coding electronic tag material and preparation method thereof

An electronic label, alcohol-resistant technology, applied in the field of film materials, can solve the problems of inability to print extremely fine codes, the printing effect cannot be achieved, and it is not resistant to solvents such as alcohol, etc., and achieves excellent ultra-fine coding effect and good antistatic effect. , Good effect of alcohol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

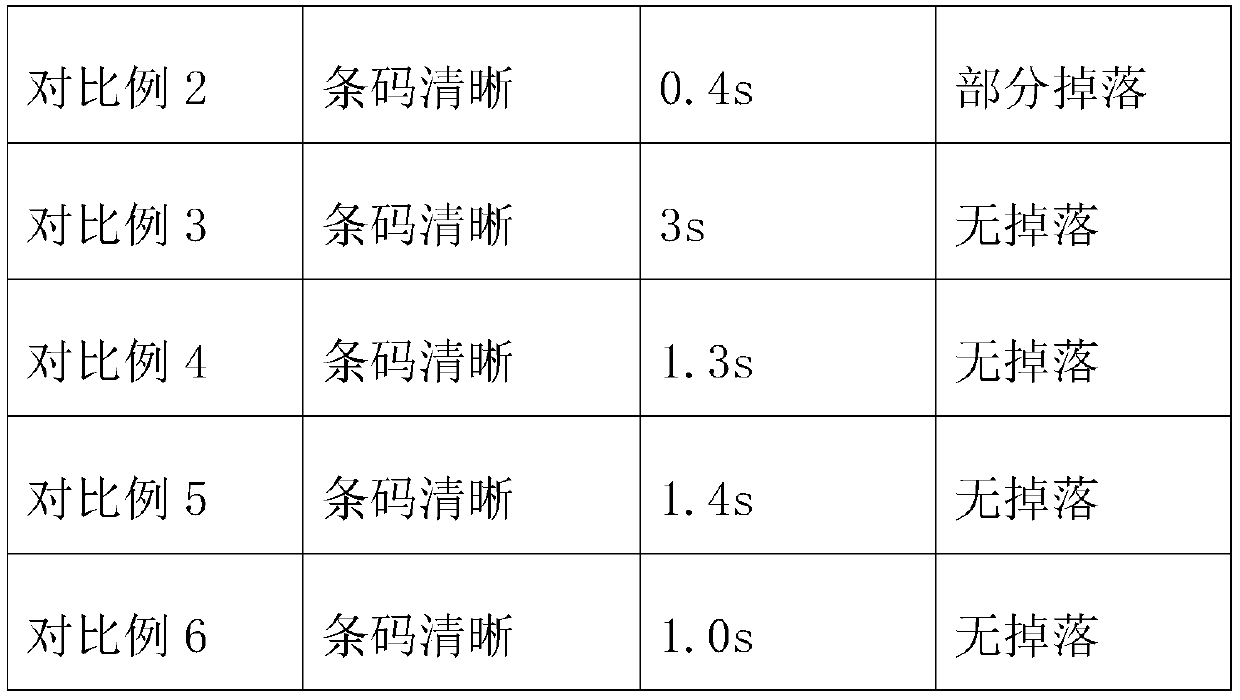

Examples

Embodiment 1

[0024] An alcohol-resistant friction ultra-fine coded electronic label material, including from top to bottom: nano-scale ultra-fine code printing coating, nano-scale antistatic matte black ink, matte black PET, high-viscosity oily acrylic adhesive layer, PET release Base paper.

[0025] Among the raw materials of the nano-scale ultra-fine code printing coating: water-based polyurethane, water-soluble nano-scale silica sol, hydrogen peroxide, ethylenediaminetetraacetic acid, and water, the ratio is 100:10:2:5:200. The preparation method of the nano-scale ultra-fine coding printing coating is as follows: dissolve the water-based polyurethane in water, keep stirring and heat to 60°C, add dropwise ethylenediaminetetraacetic acid, then slowly add water-soluble nano-scale silica sol, and finally Add hydrogen peroxide and keep stirring rapidly until it becomes a paste, then it can be used for coating.

[0026] Among the components of the nano-scale antistatic matte black ink: the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com