Nano flame-retardant antistatic air duct cloth and preparation method thereof

A flame-retardant, anti-static, and nano-flame-retardant technology, which is applied in the field of mine flame-retardant materials, can solve problems such as air leakage, covering film shedding, and broken leather air ducts, and achieves the effects of reducing production costs, good confidentiality performance, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a nano-flame retardant and antistatic air duct cloth and its preparation method. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

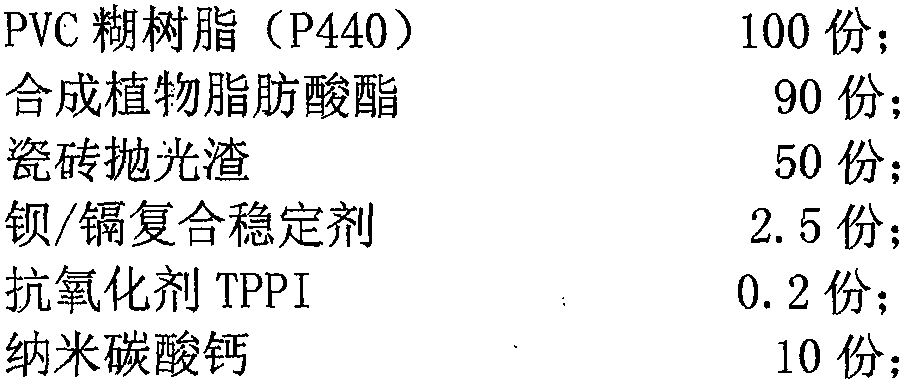

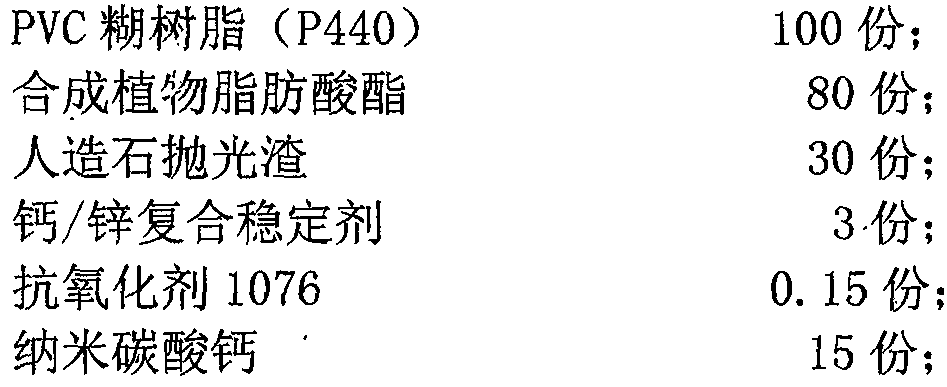

[0031] Implementation example one:

[0032] 1. Mixture:

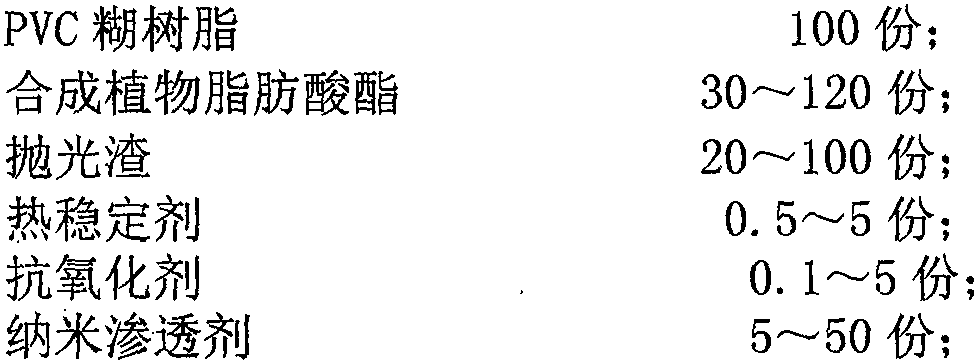

[0033] The raw materials in the following formula are weighed in parts by mass, for subsequent use:

[0034]

[0035] Put the above-mentioned prepared raw materials except synthetic vegetable fatty acid ester into the high-speed mixer and stir for 10 minutes. When the temperature of the material reaches 105-110°C, discharge it into the low-speed cold mixer and stir until the temperature of the material is lower than 50°C. Time to discharge, spare.

[0036] 2. Paste making:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com