Glass fiber reinforced PA6 composite material capable of improving floating fiber phenomenon and achieving high surface smoothness and preparation method thereof

A composite material and high surface technology, applied in the field of polyamide, can solve the problems of no popularization and application, complex manufacturing process, limited improvement effect, etc., and achieve the effects of low preparation cost, simple manufacturing process, and suitability for commercial promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

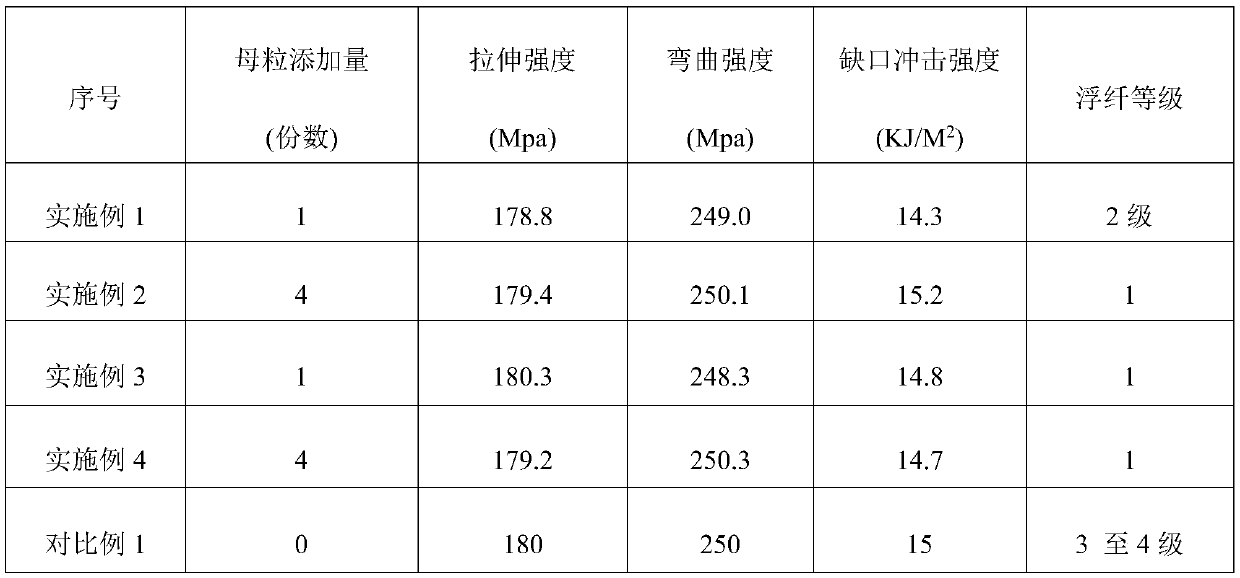

Examples

Embodiment 1

[0048] (1) Preparation of improved floating fiber, high surface finish functional masterbatch:

[0049] In parts by weight, 76.5 parts of hyperbranched nylon 6 resin made by the laboratory, 20 parts of lubricant, 0.5 part of antioxidant, and 3 parts of polyamide 6 maleic anhydride grafts are added to the high-speed mixer together. After mixing evenly, it is then added to a twin-screw extruder, melted, extruded, cooled, and pelletized to prepare functional masterbatches with improved floating fibers and high surface smoothness.

[0050] The processing setting temperatures of zones I to X of the twin-screw extruder are 220°C, 225°C, 230°C, 230°C, 235°C, 235°C, 235°C, 235°C, 240°C, and 240°C. The rotational speed of the main screw is 250r / min, and the temperature of the water tank is 30°C.

[0051] (2) Preparation of low floating fiber, high surface finish short glass fiber reinforced polyamide 6 composite material:

[0052] In parts by weight, by parts by weight, 1 part of the h...

Embodiment 2

[0055] (1) Preparation of improved floating fiber, high surface finish functional masterbatch:

[0056] In parts by weight, 76.5 parts of hyperbranched nylon 6 resin made by the laboratory, 20 parts of lubricant, 0.5 part of antioxidant, and 3 parts of polyamide 6 maleic anhydride grafts are added to the high-speed mixer together. After mixing evenly, it is then added to a twin-screw extruder, melted, extruded, cooled, and pelletized to prepare functional masterbatches with improved floating fibers and high surface smoothness.

[0057] The processing setting temperatures of zones I to X of the twin-screw extruder are 220°C, 225°C, 230°C, 230°C, 235°C, 235°C, 235°C, 235°C, 240°C, and 240°C. The rotational speed of the main screw is 250r / min, and the temperature of the water tank is 30°C.

[0058] (2) Preparation of low floating fiber, high surface finish short glass fiber reinforced polyamide 6 composite material:

[0059] In parts by weight, by parts by weight, 4 parts of th...

Embodiment 3

[0062] (1) Preparation of improved floating fiber, high surface finish functional masterbatch:

[0063] In parts by weight, hyperbranched nylon 6 resin made by the laboratory: 51 parts, lubricant: 45 parts, antioxidant 1.0 part, polyamide 6 maleic anhydride graft: 3 parts are added to the high-speed mixer together After mixing evenly in the medium, it is added to the twin-screw extruder, melted, extruded, cooled, and pelletized by the twin-screw extruder to prepare functional masterbatches with improved floating fibers and high surface smoothness.

[0064] The processing temperatures in zones I to X of the twin-screw extruder are 220°C, 225°C, 230°C, 230°C, 235°C, 235°C, 235°C, 235°C, 240°C, and 240°C in sequence. The rotational speed of the main screw is 300r / min, and the temperature of the water tank is 45°C.

[0065] (2) Preparation of low floating fiber, high surface finish short glass fiber reinforced polypropylene composite material:

[0066] In parts by weight, by par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com