Lipid wax flavor type tobacco sweetening agent, preparation method and application in cigarettes

A technology of sweetener and flavor type, which is applied in the field of tobacco flavor synthesis, can solve the problems of poor stability of DDMP, cannot be used as a sweetener, and is easy to deteriorate and damage, so as to improve aroma quality, good storage stability and flavoring Stability, effect of improving aftertaste comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

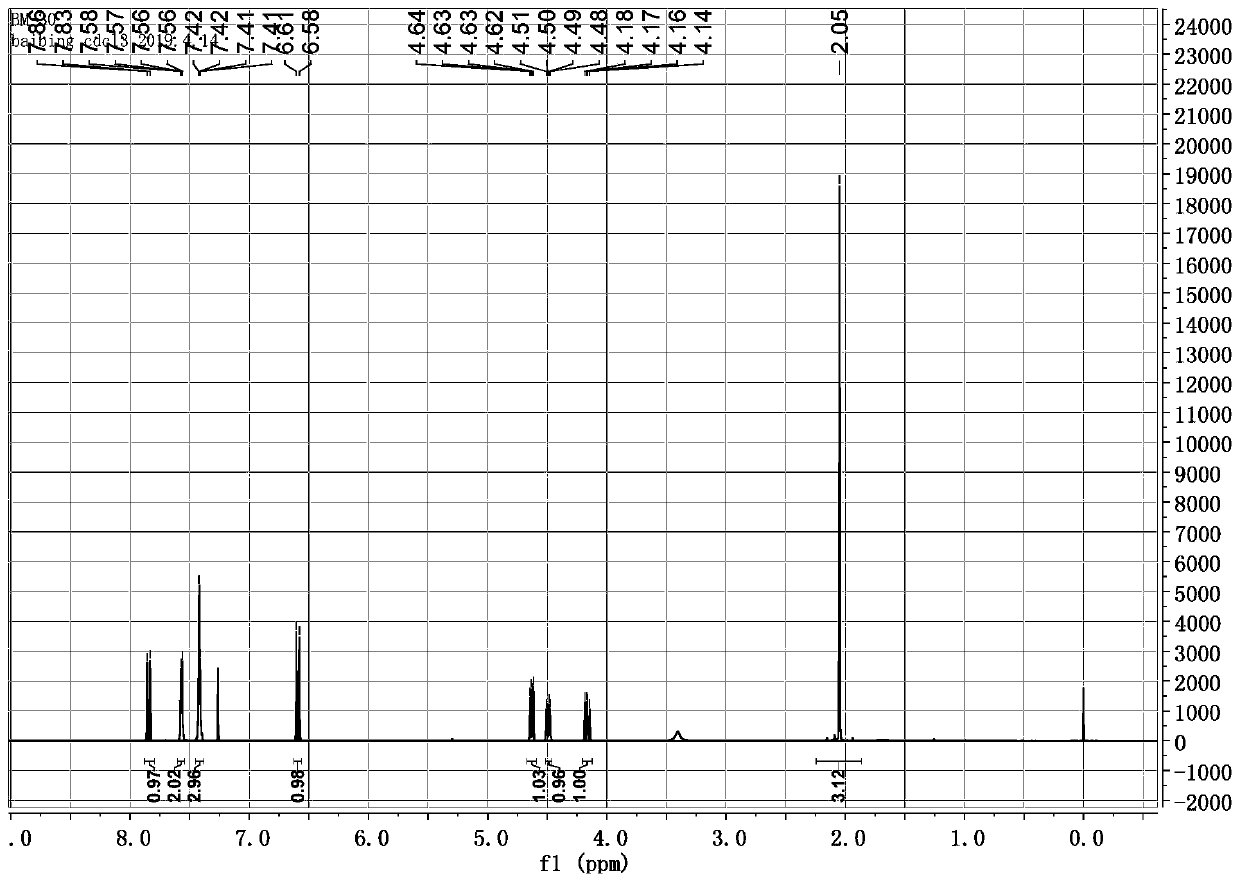

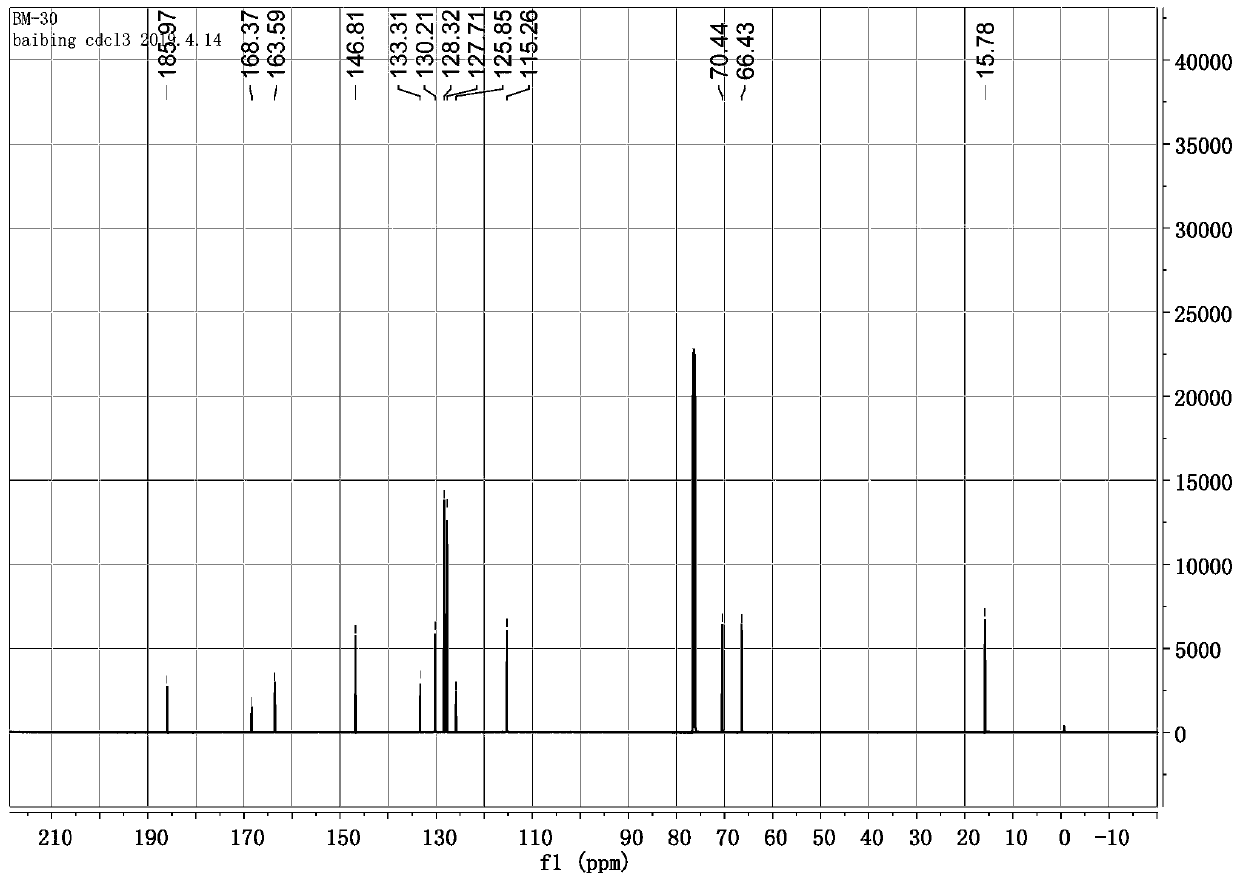

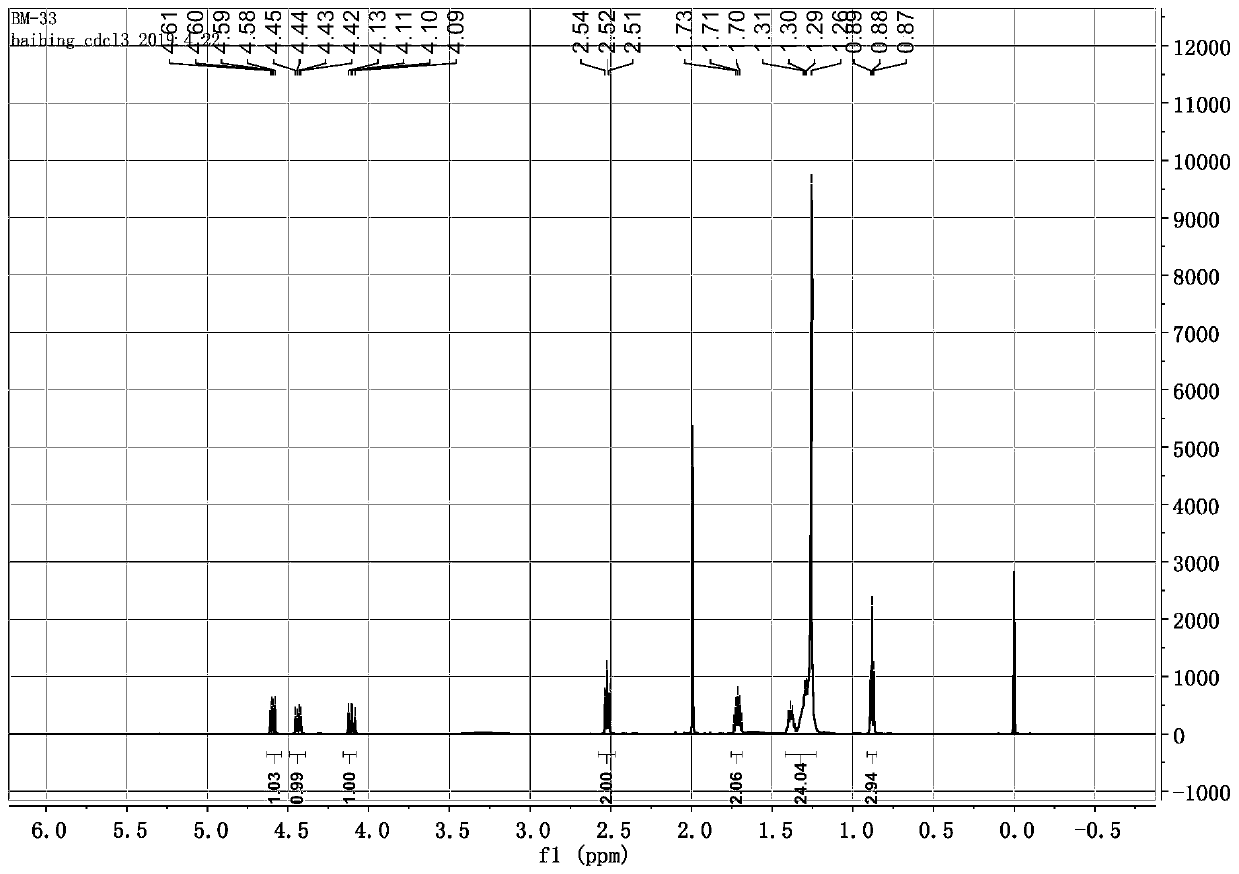

Image

Examples

preparation example Construction

[0033] The preparation method of described sweetener, comprises the following steps:

[0034] where R is

Embodiment 1

[0036] In a 100mL round bottom flask, add 2.88g DDMP (20mmol) and 30mL anhydrous dichloromethane, cool to 0°C, and under nitrogen protection, add 2.42g triethylamine (24mmol) and 2.56g palmitoyl chloride (24mmol) successively , rise to room temperature and react for 6h afterwards, after the reaction finishes, the reaction solution is washed with water and saturated sodium chloride solution 3 times successively, the organic phase is dried with anhydrous sodium sulfate, and the solvent is distilled off under reduced pressure (in this embodiment and the following each embodiment In the process, the vacuum degree of decompression is determined according to the actual situation and needs, as long as the effect of decompression distillation can be realized, and the realization of the technical solution will not be affected by the difference in vacuum degree), the crude product is separated and purified by silica gel column chromatography , Petroleum ether (V): ethyl acetate (V) = 4:1...

Embodiment 2

[0038] In a 100mL round-bottomed flask, add 2.88g DDMP (20mmol) and 30mL anhydrous toluene, cool to -5°C, under nitrogen protection, add 1.90g pyridine (24mmol) and 4.74g palmitic anhydride (30mmol) successively, then rise React at room temperature for 8 hours. After the reaction, the reaction solution was washed with water and saturated sodium chloride solution three times successively, the organic phase was dried with anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure. The crude product was separated and purified by silica gel column chromatography, and petroleum ether (V): Eluted with ethyl acetate (V)=4:1, 3.95 g of colorless oil was obtained, which was DDMP-5-palmitate, and the yield was 92.29%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com