Preparation method and application of pyrone flavor raw material capable of highlighting sweet taste characteristic of Chinese cigarettes

A technology for pyrone incense and cigarettes, which is applied in the field of tobacco flavor synthesis, can solve the problems of difficulty in realizing large-scale industrial production, low yield, and unused raw materials for tobacco flavor, and achieve potential application value and reaction yield Enhance and enrich the effect of smoke aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

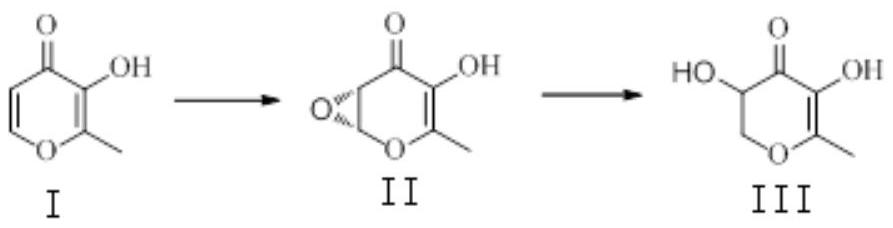

[0020] Preparation of maltol epoxide: In a 50 mL round bottom flask, add 1.26 g maltol (10 mmol), 0.58 g cobalt phthalocyanine (1.0 mmol), 0.23 g α, α, α-terpyridine (1.0 mmol) and 10 mL Acetonitrile, stirred at 25°C for 30 minutes until completely dissolved, then cooled the reaction system to 0°C, and added dropwise 0.68g of 50% H 2 o 2 aqueous solution (10mmol), reacted at 25°C for 2 hours, after the reaction was completed, 10mL of saturated Na 2 S 2 o 3 solution and saturated 10mL NaCl solution, extracted and separated to obtain the organic phase and washed with anhydrous NaCl 2 SO 4 After drying, the solvent was evaporated under reduced pressure and purified by silica gel column chromatography to obtain 1.34 g of maltol epoxide with a yield of 94.3%.

[0021] The preparation of 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one target compound: In a 100mL round bottom flask, add maltol epoxide (10mmol), 10mL tetrahydrofuran and 0.1g Pd / C, use a round-bottomed flask to...

Embodiment 2

[0023] Preparation of maltol epoxide: In a 50 mL round bottom flask, add 1.26 g maltol (10 mmol), 0.09 g cobalt hydroxide (1.0 mmol), 0.16 g 2,2'-bipyridine (1.0 mmol) and 10 mL THF was stirred at 25°C for 30 minutes until it was completely dissolved, then the reaction system was cooled to 0°C, and 0.68g of 50% H 2 o 2 Aqueous solution (10mmol), react at 25°C for 1 hour, after the reaction is completed, add 10mL saturated Na 2 S 2 o 3 solution and saturated 10mL NaCl solution, extracted and separated to obtain the organic phase and washed with anhydrous NaCl 2 SO 4 After drying, the solvent was evaporated under reduced pressure and purified by silica gel column chromatography to obtain 1.29 g of maltol epoxide with a yield of 90.8%.

[0024] The preparation of 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one target compound: In a 100mL round bottom flask, add maltol epoxide (10mmol), 10mL of acetonitrile and 0.1g of Raney nickel were replaced with nitrogen 3 times and h...

Embodiment 3

[0026] Preparation of maltol epoxide: In a 50 mL round bottom flask, add 1.26 g of maltol (10 mmol), 0.31 g of cobalt acetate (1.0 mmol), 0.18 g of 1,10-phenanthroline (1.0 mmol) and 10 mL of tetrahydrofuran , stirred at 25°C for 30 minutes until completely dissolved, then cooled the reaction system to 0°C, and added dropwise 0.68g of 50% H 2 o 2 Aqueous solution (10mmol), react at 25°C for 1 hour, after the reaction is completed, add 10mL saturated Na 2 S 2 o 3 solution and saturated 10mL NaCl solution, extracted and separated to obtain the organic phase and washed with anhydrous NaCl 2 SO 4 After drying, the solvent was evaporated under reduced pressure and purified by silica gel column chromatography to obtain 1.27 g of maltol epoxide with a yield of 89.4%.

[0027]The preparation of 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one target compound: In a 100mL round bottom flask, add maltol epoxide (10mmol), 10mL of dichloromethane and 0.1g of zinc powder, use a round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com