Method for preparing propylene glycol monomethyl ether

A technology of propylene glycol monomethyl ether and alcoholysis, which is applied in the direction of preparation of ether from alkylene oxide, preparation of ether, chemical instruments and methods, etc. It can solve the problems of runaway temperature, low work efficiency, high catalyst bed temperature, etc., and achieve high epoxy Effect of propane conversion rate and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

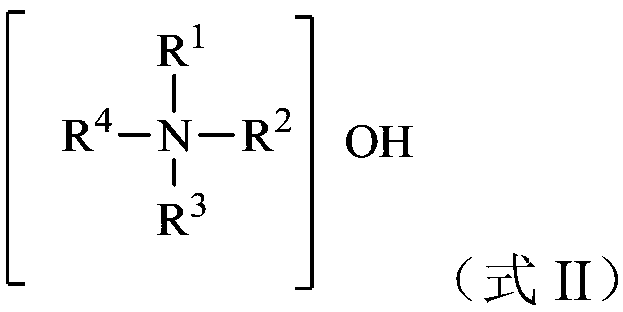

[0058] According to a preferred embodiment of the present invention, the alkali source is one or more of ammonia, aliphatic amine, aliphatic alcohol amine and quaternary ammonium base.

[0059] In the present invention, the quaternary ammonium base can be various organic quaternary ammonium bases, and the aliphatic amine can be various NH 3 A compound formed by replacing at least one hydrogen in an aliphatic hydrocarbon group (preferably an alkyl group). The aliphatic alcohol amine can be various NH 3 A compound in which at least one hydrogen is substituted by a hydroxyl-containing aliphatic hydrocarbon group (preferably an alkyl group).

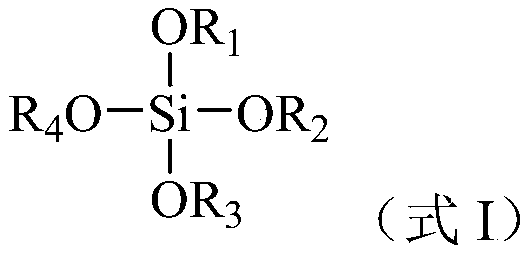

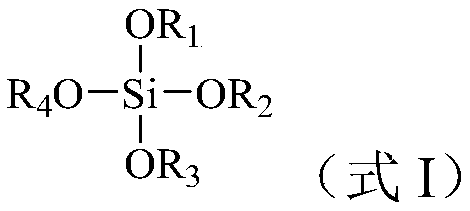

[0060] Specifically, the quaternary ammonium base may be a quaternary ammonium base represented by formula II, the aliphatic amine may be an aliphatic amine represented by formula III, and the aliphatic alcohol amine may be an aliphatic amine represented by formula IV Alcoholamine:

[0061]

[0062] In formula II, R 1 , R 2 , R 3 And R 4 Each C 1 -...

preparation example 1

[0082] Preparation of titanium silicon aluminum molecular sieve

[0083] (1) Take TS-1 molecular sieve (prepared according to the method described in "Zeolites, 1992, Vol.12: 943~950", TiO 2 The mass percentage is 2.1%) placed in a 100mL slurry bed reactor with continuous feeding and membrane separation device, and under stirring, a mixture of water and 30wt% hydrogen peroxide is added at a rate of 5.7mL / h ( The volume ratio of water to hydrogen peroxide is 10:9), the mixture of cyclohexanone and tert-butanol is added at a rate of 10.5mL / h (the volume ratio of cyclohexanone and tert-butanol is 1:2.5), and the ratio is 5.7 Add 36wt% ammonia water at the rate of mL / h. The above three streams are added at the same time and continuously discharged at the corresponding rate. The reaction temperature is maintained at 80℃. After the reaction is stable, the product is sampled every 1h. The liquid phase is measured by gas chromatography. Analyze the composition, use the following formula ...

Embodiment 1

[0093] Propylene oxide, methanol, acetone as a solvent, and molecular sieve TS-A prepared in Preparation Example 1 as a catalyst were continuously fed into the moving bed reactor to perform contact reaction. Among them, propylene oxide is fed from the lower feed port of the reactor, and the mixture of methanol and solvent and the catalyst are fed into the reactor from the liquid phase feed port and the solid phase feed port located at the top of the reactor, respectively. Among them, the feed rate of propylene oxide is 50 mL / min, the molar ratio of propylene oxide to methanol is 1:2, the weight ratio of solvent to propylene oxide is 10:1, and the weight ratio of propylene oxide to catalyst is 8. :1. The temperature in the reactor is 65°C, and the pressure in the reactor is 1.0 MPa. During operation, the catalyst output from the bottom of the reactor is directly recycled without regeneration. The reaction mixture obtained 1h and 12h after the start of the reaction was analyzed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com