Method for preparing dimethyl sulfoxide

A technology of dimethyl sulfoxide and dimethyl sulfide, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of unsuitable large-scale production and high cost of anodic oxidation, and avoid catalysts The effect of bed temperature flying and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

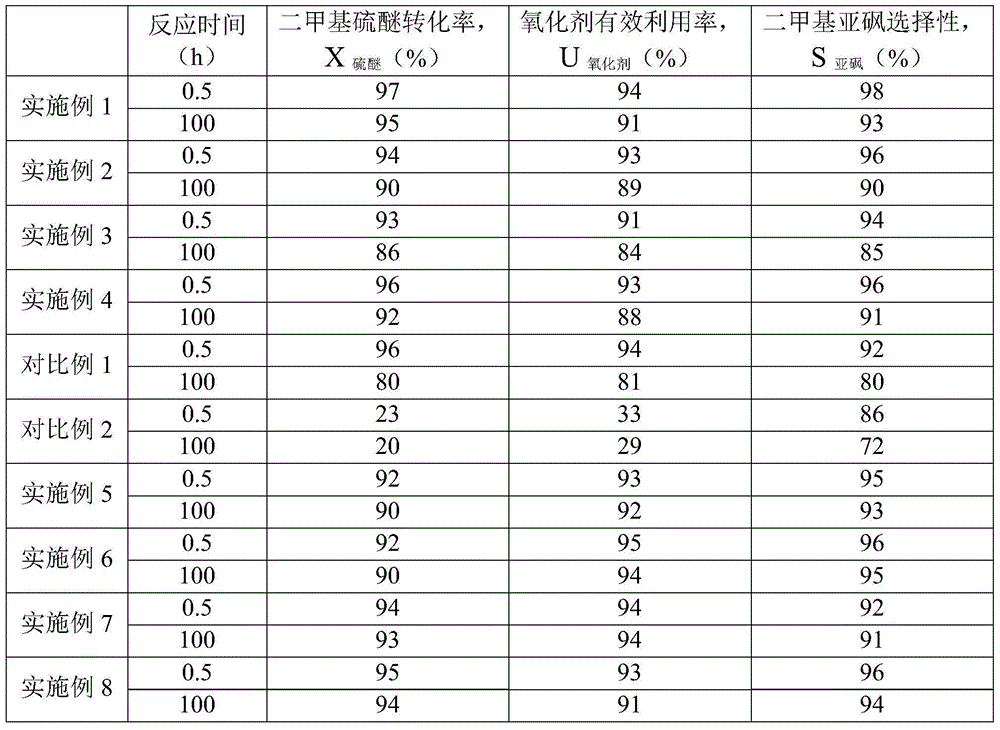

[0077] Dimethyl sulfide, oxidant, ammonia water, methanol as a solvent and hollow titanium-silicon molecular sieve HTS are respectively continuously fed into the moving bed reactor for contact reaction. Among them, dimethyl sulfide is fed from the bottom of the reactor, and the mixture of oxidant and solvent, ammonia water (concentration is 25% by weight) and titanium silicon molecular sieve are respectively fed from the liquid phase feed port at the top of the reactor, the auxiliary agent The feed port and the solid phase feed port feed into the reactor. Wherein, the oxidant is 27.5% by weight of hydrogen peroxide, the molar ratio of dimethyl sulfide to hydrogen peroxide is 1:1, the weight ratio of dimethyl sulfide to solvent is 1:5, dimethyl sulfide The feed weight ratio of ether to titanium silicon molecular sieve is 10:1, and the weight hourly space velocity of dimethyl sulfide in the reactor is 1.0h -1 , the temperature in the reactor is 60° C., the gauge pressure is 0.2...

Embodiment 2

[0080] Dimethyl sulfoxide was prepared by the same method as in Example 1, except that the hollow titanium-silicon molecular sieve HTS was replaced by the same amount of titanium-silicon molecular sieve TS-1. The reaction mixture obtained at 0.5h and 100h after the start of the reaction was analyzed by gas chromatography, and the conversion rate of dimethyl sulfide, the effective utilization rate of the oxidant and the selectivity of dimethyl sulfoxide were calculated. The results are listed in Table 1.

Embodiment 3

[0082] Dimethyl sulfoxide was prepared in the same manner as in Example 1, except that ammonia was not sent into the reactor. The reaction mixture obtained at 0.5h and 100h after the start of the reaction was analyzed by gas chromatography, and the conversion rate of dimethyl sulfide, the effective utilization rate of the oxidant and the selectivity of dimethyl sulfoxide were calculated. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com