Functional glaze as well as preparation method and application thereof

A glaze and functional technology, applied in the field of functional glaze and its preparation, can solve the problems of single function and difficulty in meeting consumers' decoration, function and safety needs at the same time, and achieve enhanced active function, excellent health care function, and elimination of irritation The effect of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

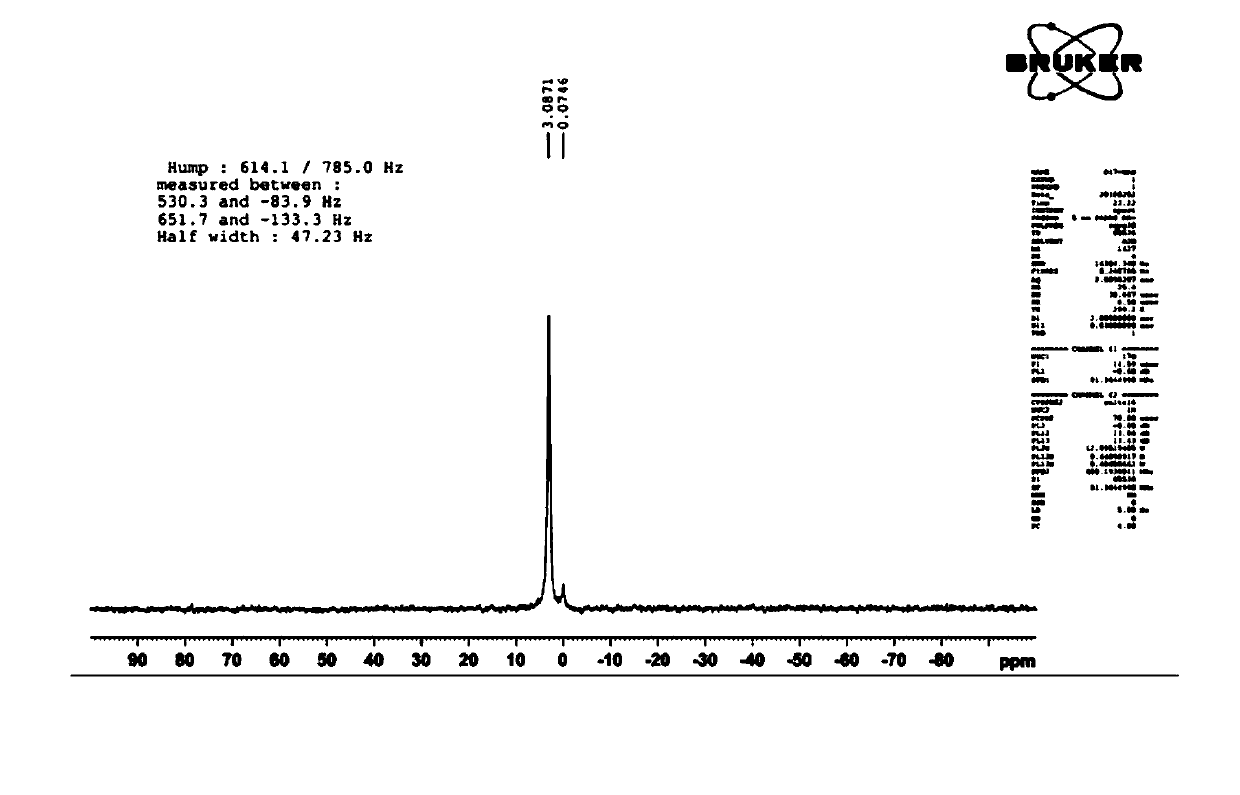

Image

Examples

Embodiment 1

[0034] A functional glaze comprises main materials, auxiliary materials and base materials in the following parts by mass:

[0035] 45 parts of main materials: 10 parts of medical stone, 3 parts of negative oxygen ion powder, 15 parts of tourmaline, 5 parts of far-infrared powder, 10 parts of six-ring stone powder, 2 parts of germanium stone;

[0036] 6 parts of auxiliary materials: 1 part of magnet, 3 parts of Muyu stone, 2 parts of meteorite;

[0037] 49 parts of base material: 6 parts of nepheline, 5 parts of potassium feldspar, 15 parts of albite, 5 parts of talc, 1 part of calcium carbonate, 2 parts of wollastonite, 15 parts of kaolin; among them, nepheline, potassium feldspar, Sodium feldspar is used as main solvent, talc, calcium carbonate and wollastonite are used as auxiliary solvents, and kaolin is used as suspending agent.

[0038] The preparation method of this functional glaze is as follows:

[0039] Weigh and mix the main materials, auxiliary materials and base...

Embodiment 2

[0042] A functional glaze comprises main materials, auxiliary materials and base materials in the following parts by mass:

[0043] 47 parts of main materials: 10 parts of medical stone, 5 parts of negative oxygen ion, 15 parts of tourmaline, 5 parts of far-infrared powder, 10 parts of six-ring stone powder, 2 parts of germanium stone;

[0044] 9 parts of auxiliary materials: 1 part of magnet, 3 parts of shell powder, 2 parts of black gold stone, 0.5 part of meteorite, 2.5 parts of diatomaceous earth;

[0045] 44 parts of base material: 2 parts of wollastonite, 5 parts of potassium feldspar, 14 parts of albite feldspar, 5 parts of talc, 2 parts of calcite, 1 part of limestone, 15 parts of kaolin; among them, wollastonite, potassium feldspar, sodium Feldspar is used as the main solvent, talc, calcite, and limestone are used as auxiliary solvents, and kaolin is used as the suspending agent.

[0046] The preparation method of this functional glaze is as follows:

[0047] Weigh ...

Embodiment 3

[0051] A functional glaze comprises main materials, auxiliary materials and base materials in the following parts by mass:

[0052] 27 parts of main materials: 5 parts of medical stone, 2 parts of negative oxygen ion powder, 10 parts of tourmaline, 3 parts of far-infrared powder, 5 parts of six-ring stone powder, and 2 parts of germanium stone;

[0053] 5 parts of auxiliary materials: 0.5 parts of magnet, 2 parts of Muyu stone, 2 parts of black gold stone, 0.5 part of meteorite;

[0054] 68 parts of base material: 40 parts of spodumene, 2 parts of quartz, 10 parts of feldspar, 3 parts of talc, 1 part of wollastonite, 1 part of limestone, 8 parts of kaolin, 3 parts of bentonite; among them, spodumene, quartz, Feldspar is used as the main solvent, talc, wollastonite and limestone are used as auxiliary solvents, and kaolin and bentonite are used as suspending agents.

[0055] The preparation method of this functional glaze is as follows:

[0056] Weigh and mix the main material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com