Composite diamond tool bit, manufacturing method of composite diamond tool bit, diamond saw blade and manufacturing method of diamond saw blade

A technology of diamond cutter heads and diamond saw blades, which is applied in the direction of stone processing equipment, manufacturing tools, stone processing tools, etc., can solve the problems of low diamond holding capacity, diamond particles falling off, and reduced cutting efficiency, so as to improve the service life and Cutting efficiency, improved performance, and the effect of increased cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

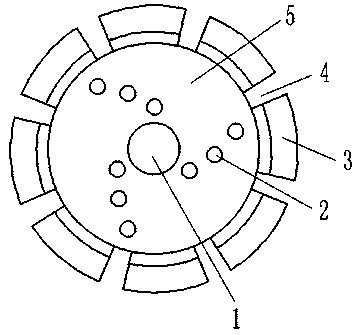

[0036] A composite diamond cutter head, including a metal matrix and several diamond particles, each diamond particle is coated with a layer of tungsten on the outside, the outside of the tungsten layer is coated with a layer of nickel, and the outermost layer is coated with each diamond particle of the nickel layer Inlaid in the metal body. Wherein, each diamond particle is evenly or randomly inlaid in the metal matrix.

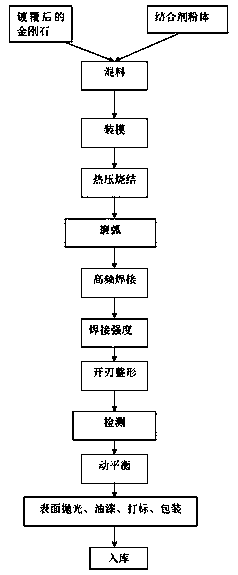

[0037] Correspondingly, its preparation method comprises the following steps:

[0038] Step 1. Plating tungsten powder on the surface of diamond particles to form a layer of tungsten layer; or, discharge the mixed powder of dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com