System and method for intelligent movable detection of cutter damage, applied to workshop or production line

A technology of mobile monitoring and cutting tools, applied in manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of low accuracy of tool damage detection models, occupying internal space of machine tools, high cost, etc., and achieve accurate and reliable diagnosis results , Reduce labor intensity and save manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

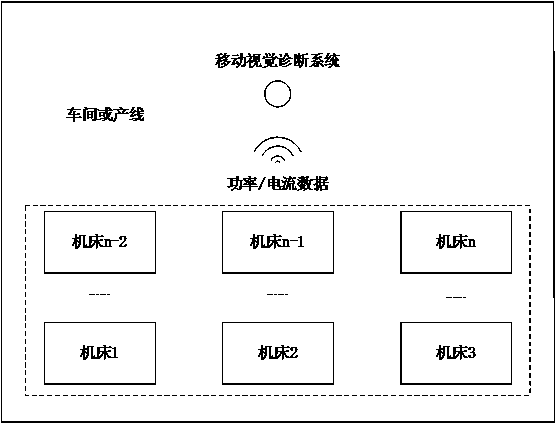

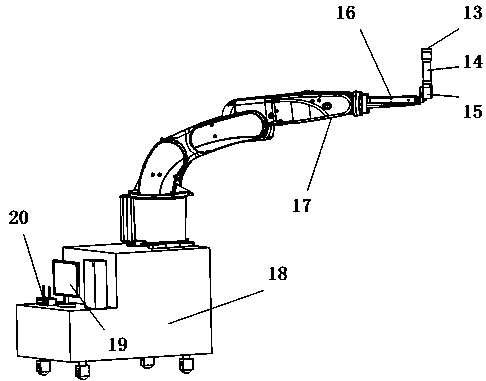

[0037] An intelligent mobile monitoring system for tool damage in a workshop or production line, characterized in that it includes a machine tool environment cleaning system, a preliminary online early warning system, a mobile vision high-precision diagnosis system, and a server 19.

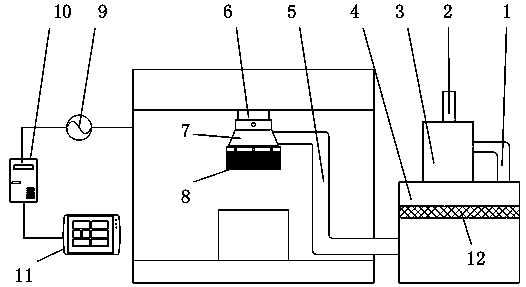

[0038] The machine tool cleaning system starts / stops synchronously with the machine tool, and is used to suck the chips, dust and oil generated during the machine tool processing into the recovery box 4 through the fan 3, so as to ensure the cleanliness of the machine tool processing environment and effectively prevent chips, dust, Oil stains and the like attached to the tool 21 affect the accuracy of tool damage detection results.

[0039] The preliminary online early warning system includes a power / current sensor 9, a data acquisition card 10, and a wireless tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com