Electrode clamping welding mechanism

An electrode clip and electrode technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inconvenient welding of the workpiece to be welded, mechanical damage at the welding point of the workpiece, and inability to quickly return to the position, and achieve convenient welding process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

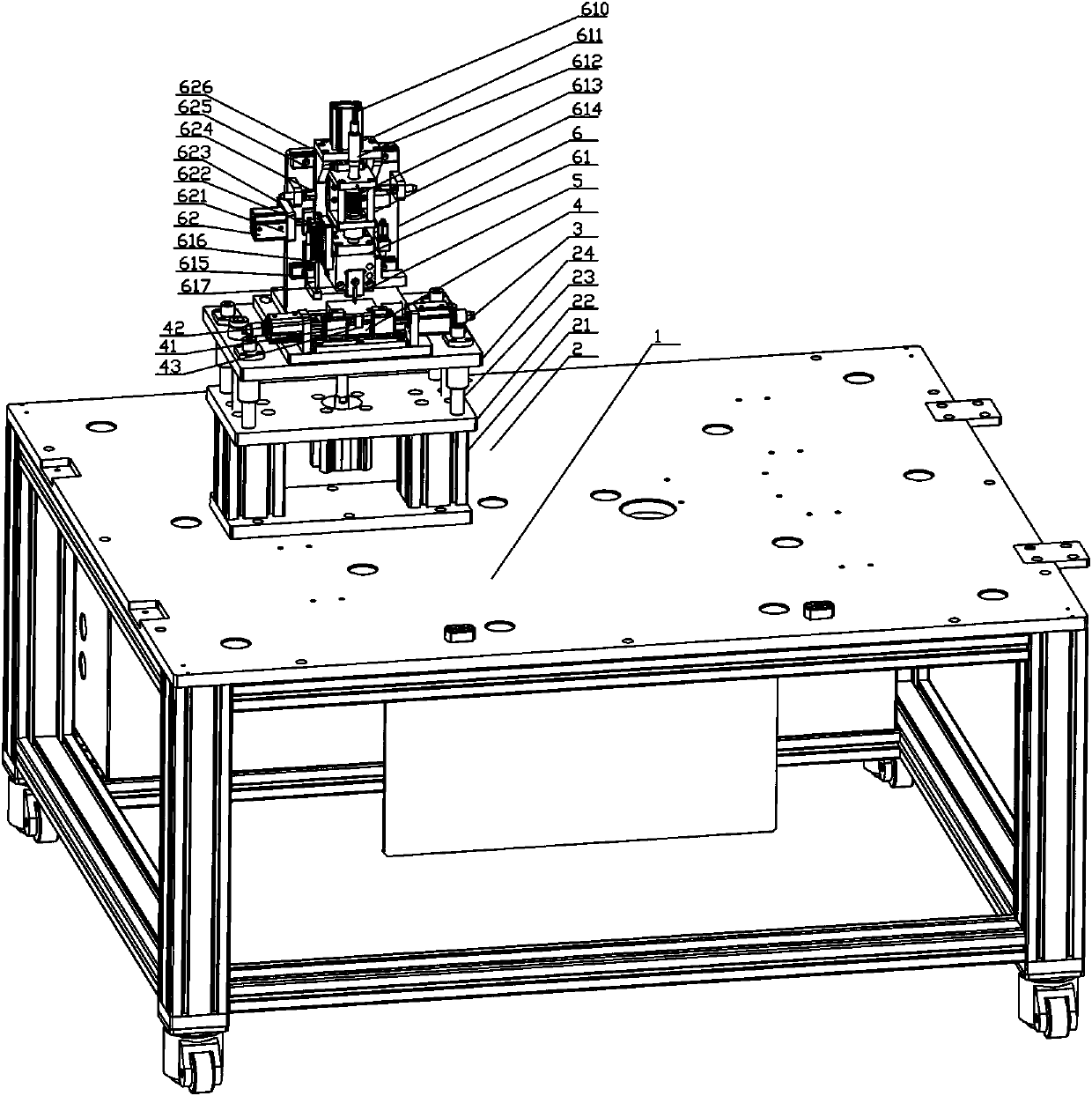

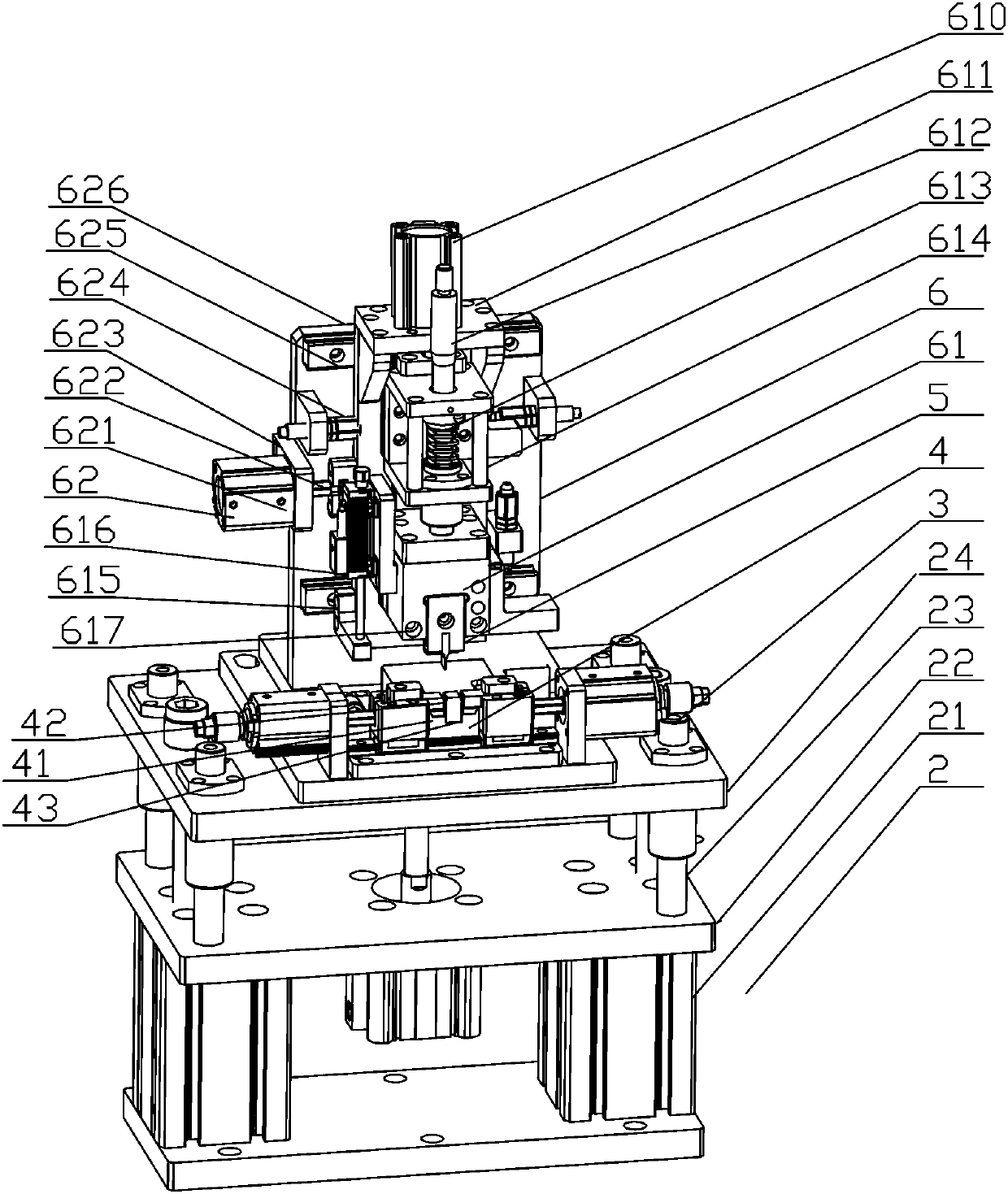

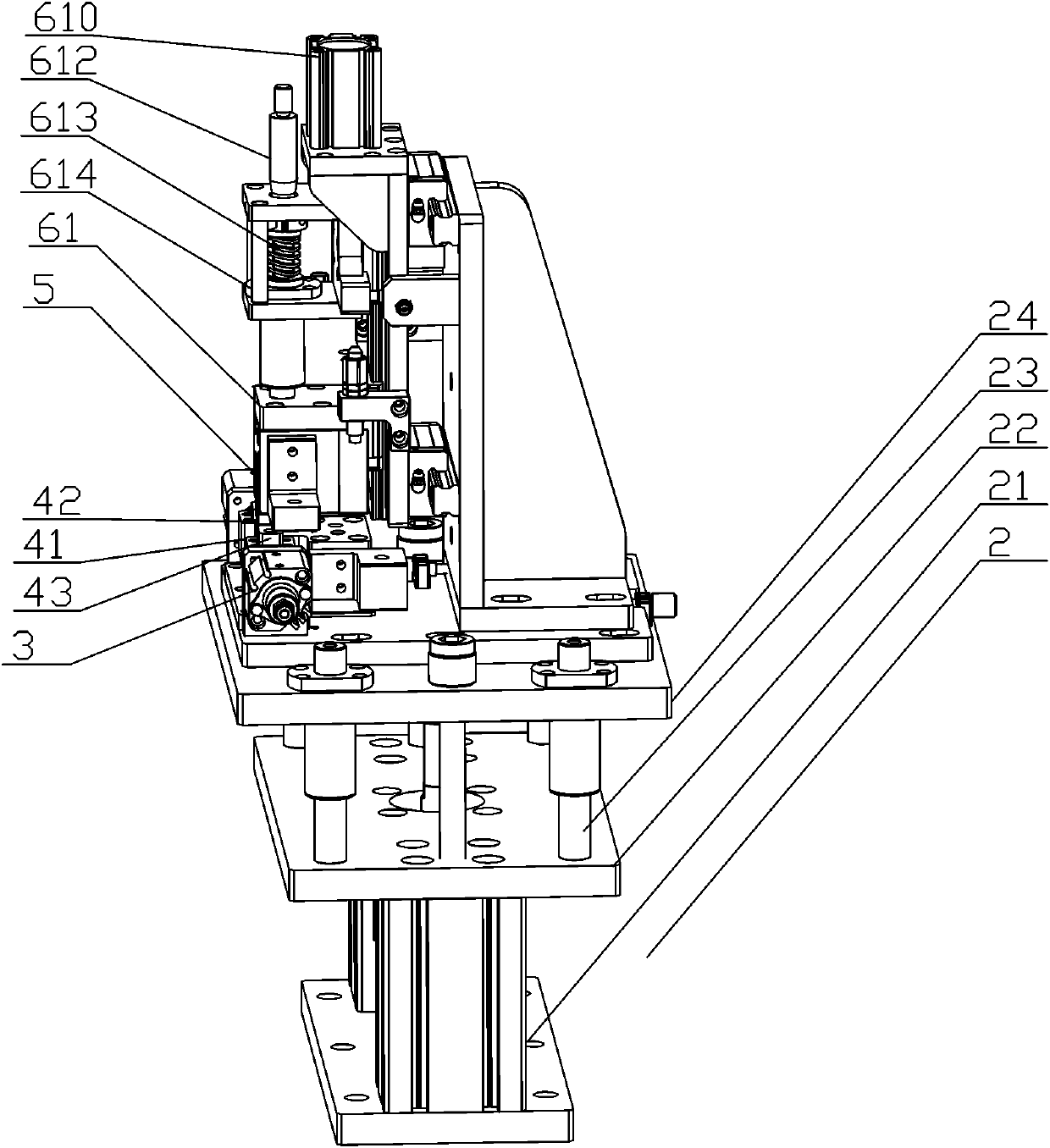

[0023] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0024] Such as Figure 1~Figure 4 As shown, this embodiment discloses an electrode clamp welding mechanism, including a clamp welding mechanism arranged on a frame 1, and a positioning mechanism 3 capable of clamping a workpiece. The clamp welding mechanism corresponds to the positioning mechanism 3 . The clamp welding mechanism includes at least a pair of lower electrode holder 4 and upper electrode holder 5 that can be opened and closed relatively.

[0025] The frame 1 is provided with a lifting mechanism 2, and one end of the lifting cylinder 21 in the lifting mechanism 2 is fixedly arranged on the frame 1, and the lifting column 23 is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com