Battery packaging method and system and battery

A technology of battery packaging and battery casing, which is applied in secondary battery manufacturing, battery pack components, battery cover/end cover, etc. It can solve the problems of leakage risk, cumbersome operation, and poor sealing of the shell, and achieve the welding process Convenient and fast, convenient and fast operation, better sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

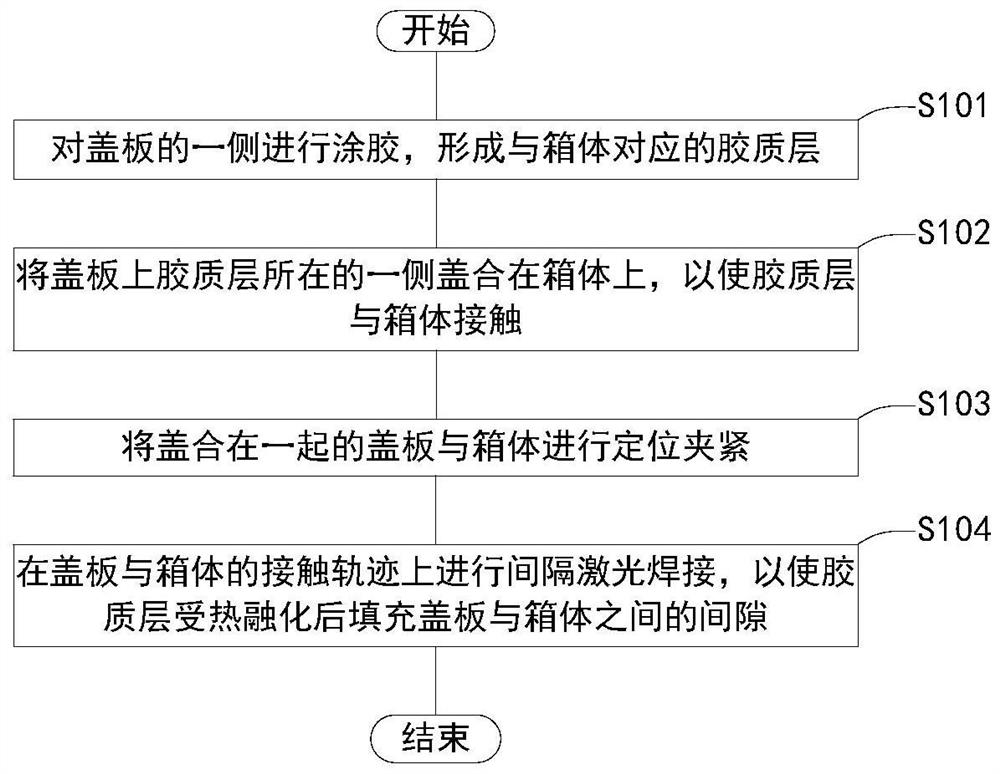

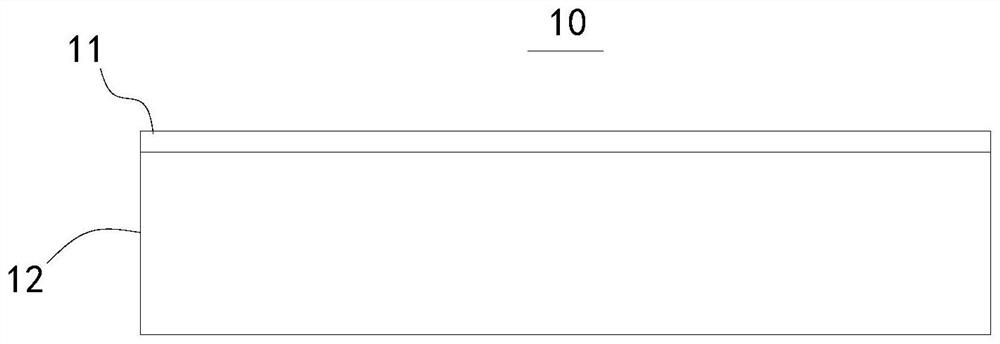

[0053] see figure 1 , figure 1 Shown is a flow chart of the battery packaging method provided in this embodiment. The battery packaging method provided in this embodiment is applied to such as figure 2 The battery casing 10 with the cover plate 11 and the box body 12 as shown has the characteristics of convenient and quick operation and better sealing, and specifically includes the following steps:

[0054] Step S101 , applying glue to one side of the cover plate 11 to form the glue layer 13 .

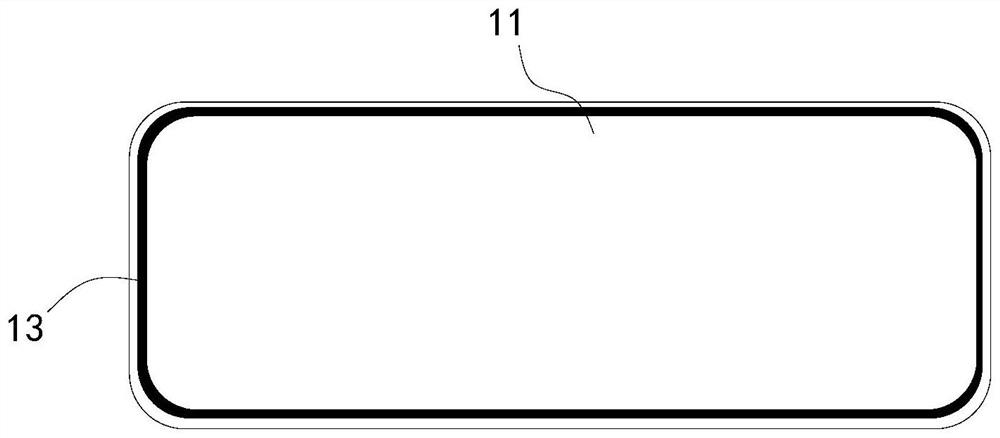

[0055] The structure of the cover plate 11 coated with glue to form the glue layer 13 is as follows: image 3 As shown, in this embodiment, the colloidal layer 13 is annular, and its shape and structure correspond to the opening of the box body 12 , so as to ensure that when the cover plate 11 is closed on the box body 12 , the colloidal layer 13 can interact with the box body 12 . The opening peripheral edge of the case 12 is in contact.

[0056] In the actual gluing process, glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com