Gradient composite Fe-Al intermetallic compound microporous filter material and preparation method thereof

An intermetallic compound and filter material technology, which is used in powder metallurgy preparation, gradient composite Fe-Al intermetallic compound microporous filter material and its preparation field, can solve the problem of single Fe-Al phase structure, difficult to form, and reduce Fe-Al High temperature corrosion resistance and other issues of filter material, to achieve the effect of good corrosion resistance and high temperature mechanical properties, high stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

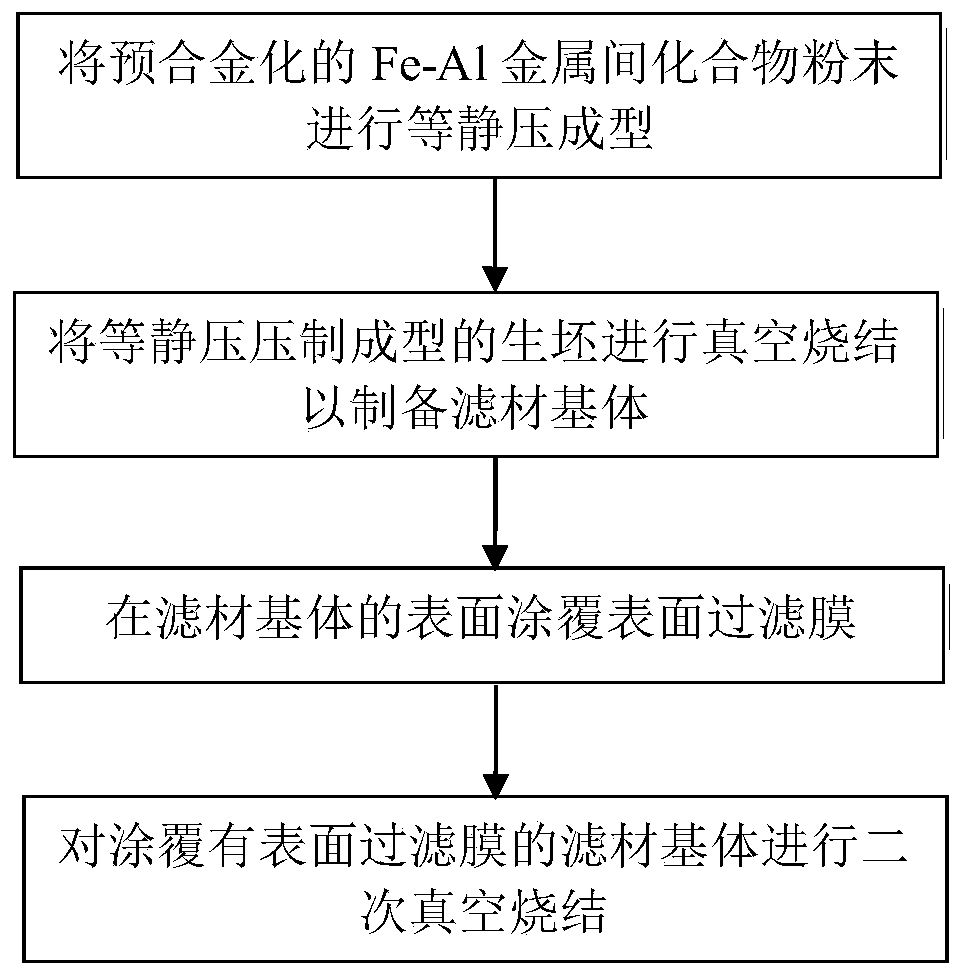

[0027] refer to figure 2 The flow chart of the present invention describes the preparation method of the gradient composite Fe-Al intermetallic compound microporous filter material of the present invention, and the concrete steps of the preparation method of the present invention include as follows:

[0028] S1. Isostatic pressing of prealloyed Fe-Al intermetallic powder

[0029] Fe-Al powder prepared from pre-alloyed Fe-Al intermetallic compound powder is filled in a mold and vibrated evenly on a vibrating platform, and then the mold is placed in a cold isostatic press for compression molding. Among them, the sieving particle size range of Fe-Al powder is -50+150 mesh, the vibration powder loading time is 30-60s (preferably 60s), the molding pressure is 150-250MPa (preferably 200MPa), and the holding time is 3-15min (preferably 5min ).

[0030] S2. Vacuum sintering the green compact formed by isostatic pressing to prepare the filter matrix

[0031] Load the furnace. Put ...

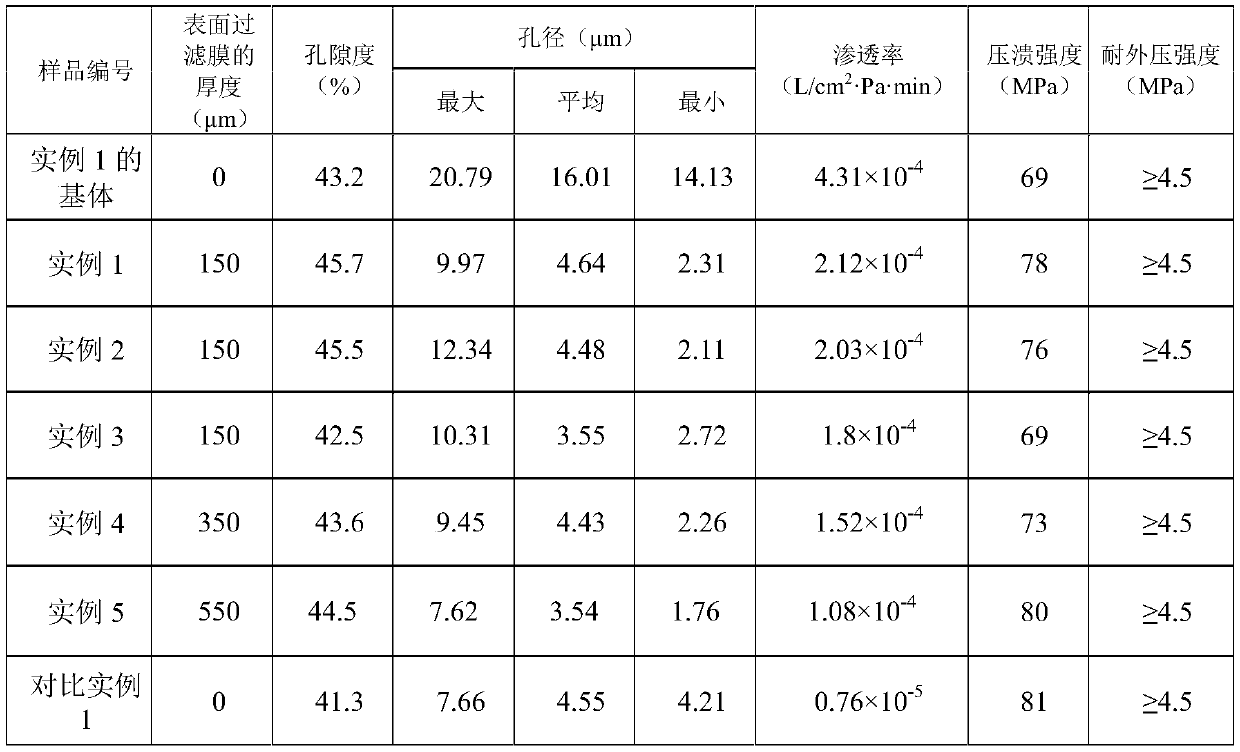

example 1

[0044] 1) Isostatic pressing. Choose -50+100 mesh pre-alloyed water atomized Fe 3 Al powder is the raw material. In order to ensure that the powder is evenly loaded, the powder is loaded and vibrated for 60S, and put into a cold isostatic press at 180MP for 5 minutes. Filter base size φ60*2000*5mm.

[0045] 2) Vacuum-confined sintering. Put the pressed tube blank filter element into the sintering boat. In order to prevent the tube blank from bending and deforming vertically, the tube blank is vertically placed in the sintering boat and flexible constraints are buried around it for vacuum high-temperature constrained sintering. The sintering process is 1h-600°C (that is, temperature rises from room temperature to 600°C within 1h), heat preservation for 0.5h, 1.5h-900°C (that is, continue to heat up to 900°C within 1.5h), heat preservation for 0.5h, 3h -1260°C (that is, continue to heat up to 1260°C within 3h), keep warm for 3h. Cool in the furnace to 500°C and then air coo...

example 2

[0049] 1) Isostatic pressing. Choose -50+100 mesh pre-alloyed water atomized Fe 3 Al powder is the raw material. In order to ensure that the powder is evenly loaded, the powder is loaded and vibrated for 30 seconds, and placed in a cold isostatic press at 150 MP for 15 minutes. Filter base size φ60*2000*5mm.

[0050] 2) Vacuum-confined sintering. Put the pressed tube blank filter element into the sintering boat. In order to prevent the tube blank from bending and deforming vertically, the tube blank is vertically placed in the sintering boat and flexible constraints are buried around it for vacuum high-temperature constrained sintering. The sintering process is 2h-500℃, heat preservation for 0.5h, 1h-800℃, heat preservation for 1h, 3h-1300℃, heat preservation for 1h. Cool in the furnace to 600°C and then air cool to room temperature to prepare the filter element matrix.

[0051]3) Coating the surface filter membrane. Choose -500 mesh pre-alloyed gas atomized Fe 3 Al pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Crush strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com