Coupling Vibration Casting Method for Improving the Surface Quality of Continuous Casting Ingots

A technology of coupling vibration and surface quality, applied in the field of metal casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

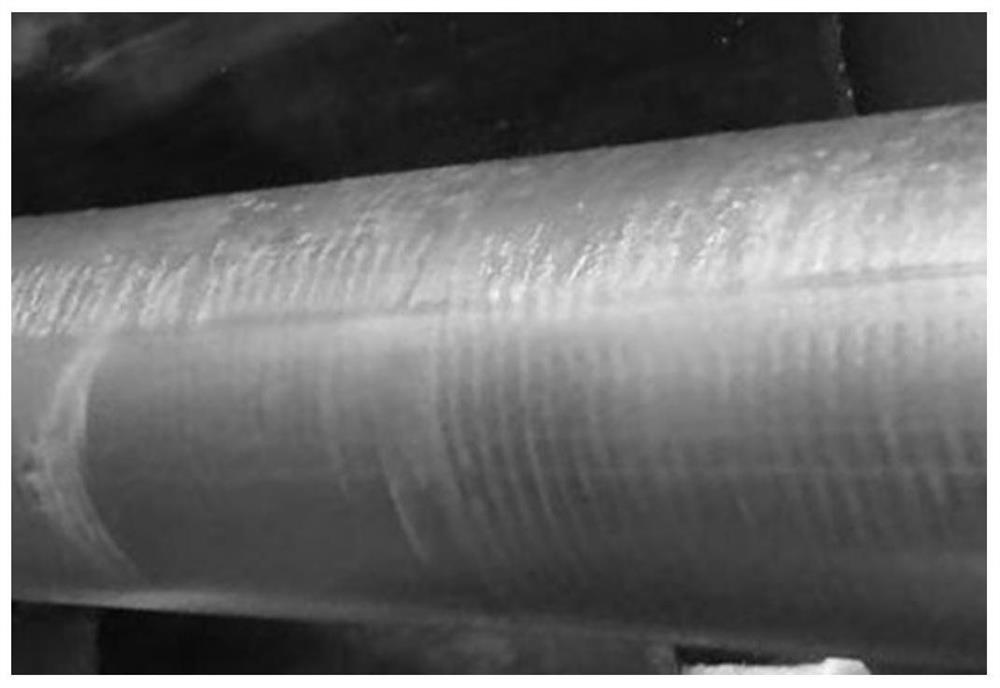

[0035] In Example 1, the above-mentioned coupled vibration casting method for improving the surface quality of the continuous casting ingot was used to cast 70Cu+As copper tubes.

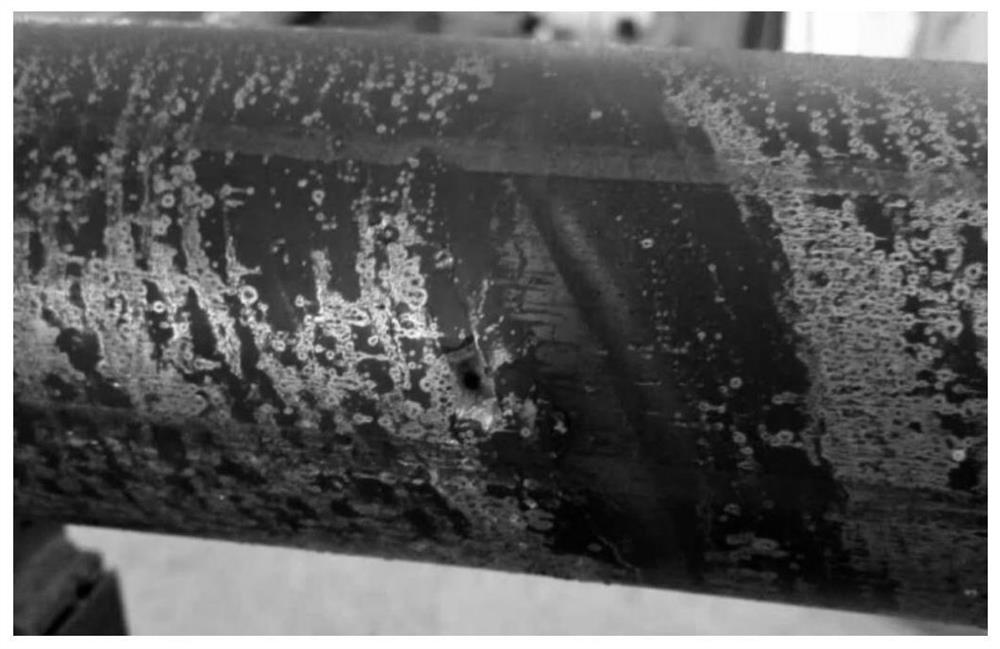

[0036] The 70Cu+As alloy pipe has good anti-Zn removal performance due to the addition of As, so it is widely used in bathrooms, decorations, etc. Thermoplasticity causes hot embrittlement, which makes alloy pipes prone to cracks in the vertical and casting direction during horizontal continuous casting.

[0037] Ingot composition: 30% Zn, 0.05% As, and the balance is Cu.

[0038] Process parameters: The medium frequency vibration frequency of the crystallizer is 500Hz, and the low frequency vibration frequency of the pipe end is 200Hz.

[0039] Process steps:

[0040] According to the above-mentioned metal composition, the smelting of 70Cu+As alloy is carried out;

[0041] The smelted melt is introduced into the holding furnace for casting, and when the temperature of the melt is controlled to b...

Embodiment 2

[0046] In Example 2, the above-mentioned coupled vibration casting method for improving the surface quality of the continuous casting ingot was used to cast 70Cu+As copper tubes.

[0047] Ingot composition: 30% Zn, 0.05% As, and the balance is Cu.

[0048] Process parameters: The medium frequency vibration frequency of the crystallizer is 800Hz, and the low frequency vibration frequency of the pipe end is 200Hz.

[0049] Process steps:

[0050] According to the above-mentioned metal composition, the smelting of 70Cu+As alloy is carried out;

[0051] The smelted melt is introduced into the holding furnace for casting, and when the temperature of the melt is controlled to be 50-70°C above the melting point of the alloy, the flow casting is started, and the medium-frequency vibration of the crystallizer and the low-frequency vibration of the pipe end are turned on at the same time;

[0052] The position of the vibrating head of the crystallizer is set within 1 / 3 to 1 / 2 of the l...

Embodiment 3

[0056] In Example 3, the above-mentioned coupled vibration casting method for improving the surface quality of the continuous casting ingot was used to cast 70Cu+As copper tubes.

[0057] Ingot composition: 30% Zn, 0.05% As, and the balance is Cu.

[0058] Process parameters: The medium frequency vibration frequency of the crystallizer is 1000Hz, and the low frequency vibration frequency of the pipe end is 200Hz.

[0059] Process steps:

[0060] According to the above-mentioned metal composition, the smelting of 70Cu+As alloy is carried out;

[0061] The smelted melt is introduced into the holding furnace for casting, and when the temperature of the melt is controlled to be 50-70°C above the melting point of the alloy, the flow casting is started, and the medium-frequency vibration of the crystallizer and the low-frequency vibration of the pipe end are turned on at the same time;

[0062] The position of the vibrating head of the crystallizer is set within 1 / 3 to 1 / 2 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com