Lithium ion battery self-discharge screening and matching method

A lithium-ion battery and self-discharge technology, applied in the field of lithium-ion, can solve the problems of harshness, irreversibility, capacity attenuation of lithium-ion batteries, etc., and achieve the effect of ensuring product quality requirements, convenient operation, and improving cycle performance and safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

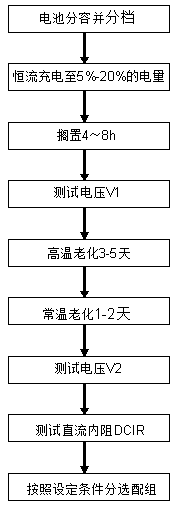

[0022] like figure 1 As shown, the present invention provides a method for self-discharging screening and grouping of lithium-ion batteries, charging the batteries after capacity division to the preset state of charge, and selecting alternative batteries whose battery voltage is within the set range, including the following step:

[0023] Step 1: Lithium-ion battery is charged and discharged;

[0024] Step 2: Classify the capacity of the batteries sorted out in Step 1 according to a fluctuation tolerance of 1%;

[0025] Step 3: Test the batteries classified in the above steps separately, and charge them with a constant current of less than 0.2C to a capacity of 5%-20%;

[0026] Step 4: Shelve for 4-8 hours at a temperature of 25°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com