A vein bionic piezo-osmotic three-in-one bipolar plate and its working method

A bipolar plate and three-in-one technology, applied in electrochemical generators, fuel cell parts, fuel cells, etc., can solve the problems of overheating of electrochemical reaction devices, improve energy utilization efficiency, simplify structure, and improve Effect of the Quick Response Feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

[0044] In the drawings, components with the same structure are denoted by the same numerals, and components with similar structures or functions are denoted by similar numerals. The size and thickness of each component shown in the drawings are shown arbitrarily, and the present invention does not limit the size and thickness of each component. In order to make the illustration clearer, the thickness of parts is appropriately exaggerated in some places in the drawings.

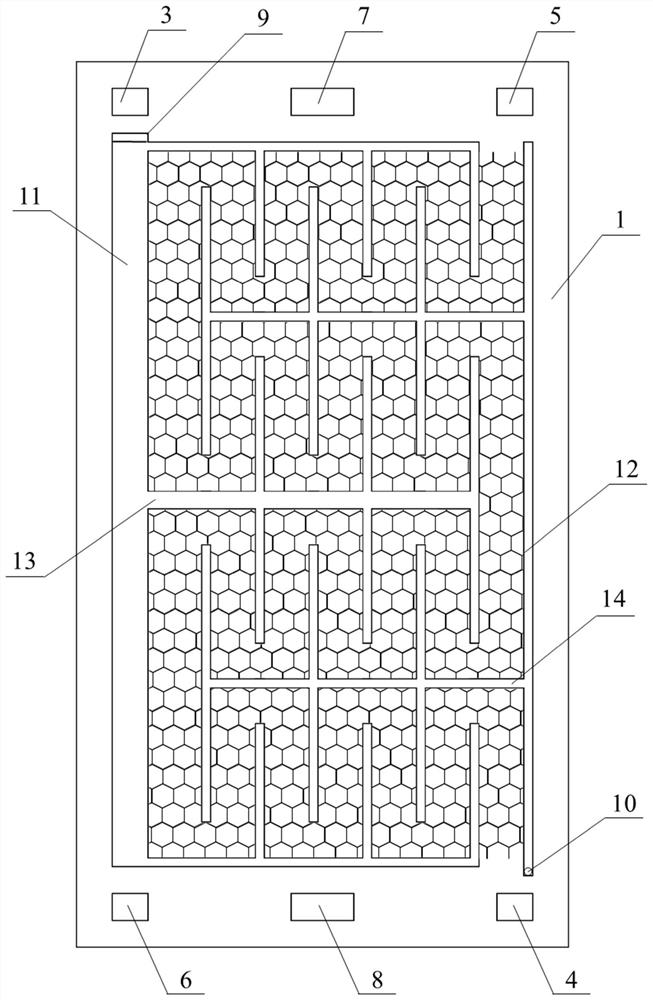

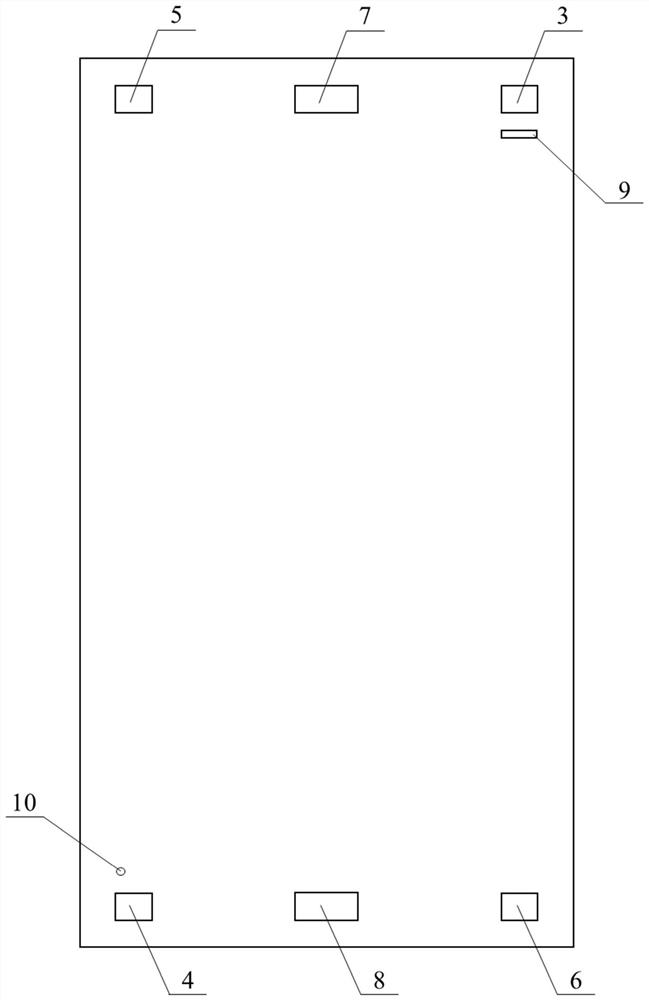

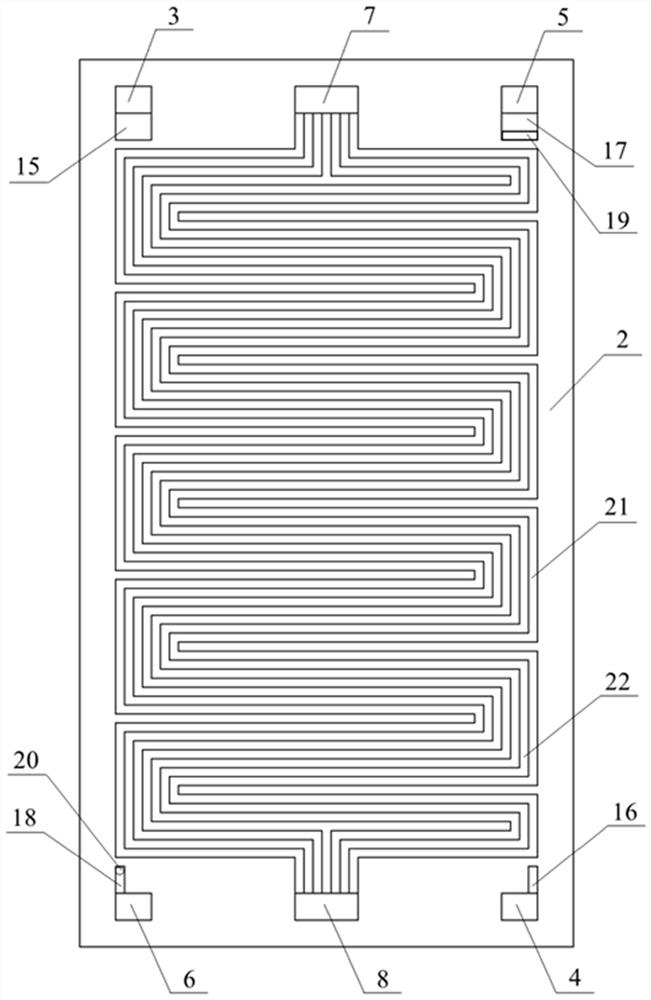

[0045] see Figure 1-4 , the leaf vein bionic piezo-osmotic three-in-one bipolar plate of the present invention includes a cathode plate 1 and an anode plate 2, and the cathode plate 1 and the anode plate 2 are tightly bonded by an adhesive to form the entire bipolar plate; The oxidant liquid distribution chamber 3, the cooling liquid liquid distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com