Ground experiment system and experiment method for preparing porous ice layer through 3D printing

A technology of 3D printing and experimental method, which is applied in the testing of machine/structural components, measuring devices, instruments, etc. It can solve the problems of difficult aircraft deicing experiments, difficult to control the physical properties of the ice layer, poor uniformity of the ice layer, etc. Simple, controllable porosity, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0034] The present invention discloses a ground experimental system for preparing porous ice layers by 3D printing. In order to make the substantive features of the present invention and its practicability easier to understand, the following is a description of the present invention with reference to the accompanying drawings. Further detailed description of the technical solution. But the following descriptions and illustrations about the embodiments do not constitute any limitation to the protection scope of the present invention.

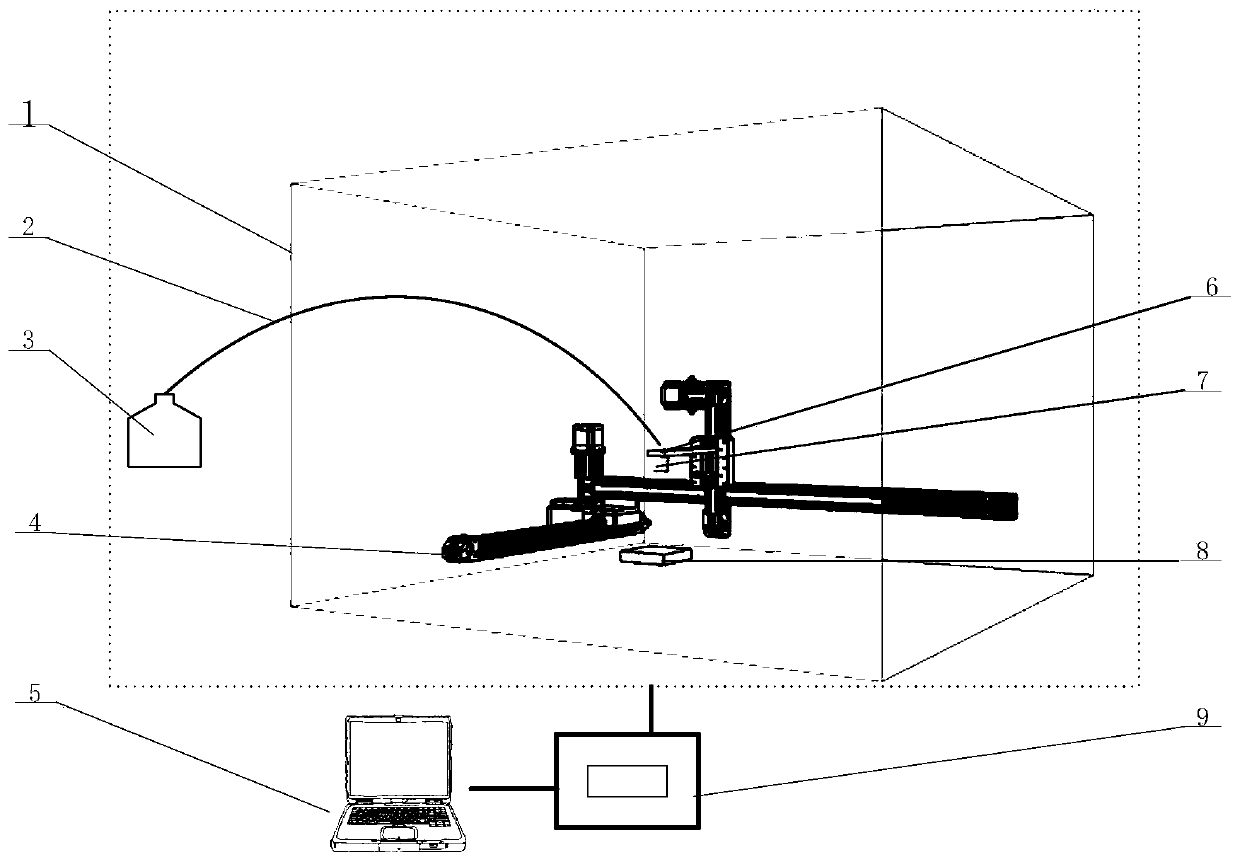

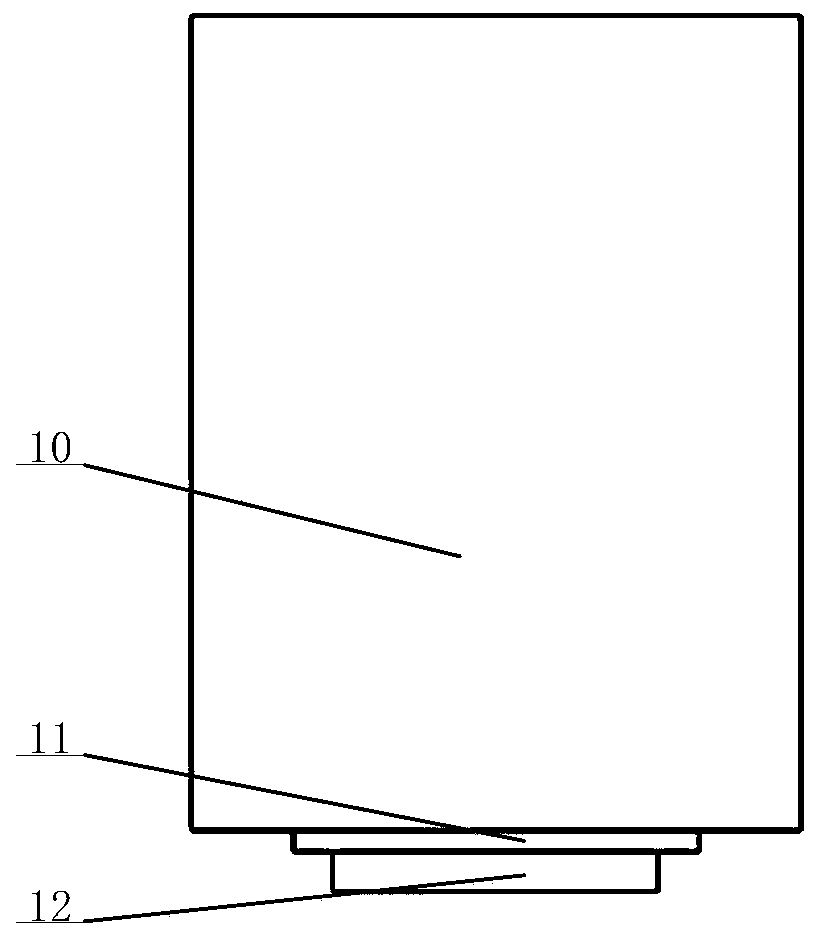

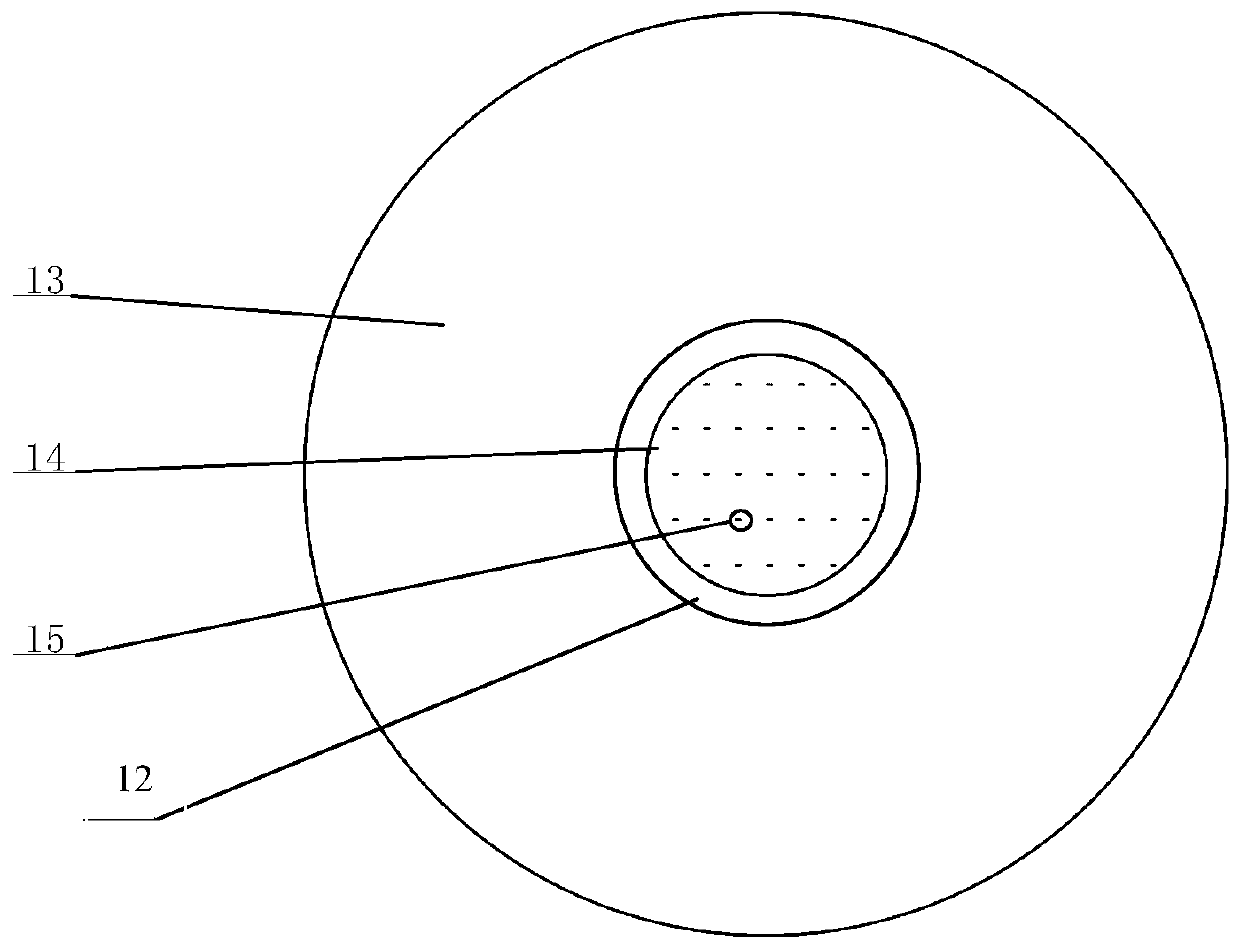

[0035] see figure 1 As shown, the present invention discloses a ground experimental system for preparing porous ice layers by 3D printing, including a cold environment box 1 , a peristaltic pump 3 , a three-axis guide rail 4 , a piezoelectric sprayer 7 , and a control unit 9 . Among them, the icing substrate 8 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com