Processing technology of zinc-nickel plating alloy

A processing technology, zinc-nickel technology, applied in the field of zinc-nickel alloy processing technology, can solve the problems of poor repeatability, complex process, insufficient corrosion resistance, oxidation resistance and thermal stability, etc., to improve the appearance The effect of high degree, simple process operation, smooth and complete appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

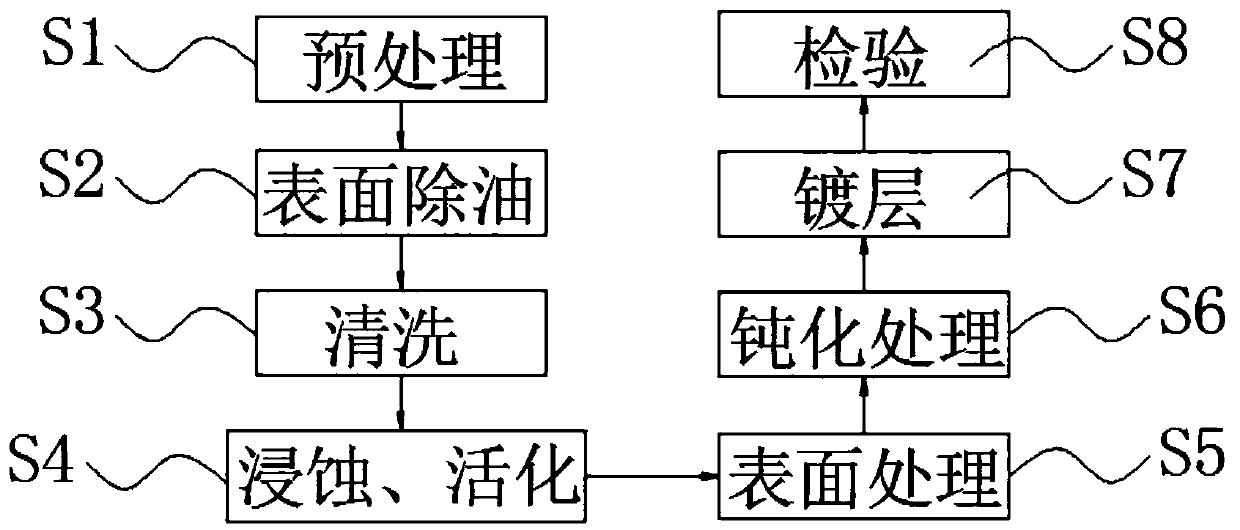

[0034] A kind of processing technology of galvanized nickel alloy, its processing technology is the following steps:

[0035] S1: Pretreatment, remove the dirt, metal shavings, marks and other attachments on the surface of the workpiece;

[0036] S2: Degreasing the surface, degreasing the large amount of oil stains on the surface of the workpiece;

[0037] S3: Cleaning, using clean flowing water to rinse the workpiece after degreasing in S2, and then hang it;

[0038] S4: Etching and activation, put the workpiece in S3 into the etching solution for immersion, keep the temperature at 20-30°C, and the time is 0.5-3min, it is convenient to remove the slight rust on the surface of the workpiece, activate the metal, and then use running water rinse, dry;

[0039] S5: coating, the workpiece etched by S4 is electroplated with a zinc-nickel alloy plating solution, and after the electroplating is completed, it is rinsed with running water and then dried;

[0040] S6: passivation tre...

Embodiment 2

[0058] A kind of processing technology of galvanized nickel alloy, its processing technology is the following steps:

[0059] S1: Pretreatment, remove the dirt, metal shavings, marks and other attachments on the surface of the workpiece;

[0060] S2: Degreasing the surface, degreasing the large amount of oil stains on the surface of the workpiece;

[0061] S3: Cleaning, using clean flowing water to rinse the workpiece after degreasing in S2, and then hang it;

[0062] S4: Etching and activation, put the workpiece in S3 into the etching solution for immersion, keep the temperature at 20-30°C, and the time is 0.5-3min, it is convenient to remove the slight rust on the surface of the workpiece, activate the metal, and then use running water rinse, dry;

[0063] S5: coating, the workpiece etched by S4 is electroplated with a zinc-nickel alloy plating solution, and after the electroplating is completed, it is rinsed with running water and then dried;

[0064] S6: passivation tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com