Rose gold color system adjusting and testing coating technology by replacing gold target

A rose and gold technology, applied in the field of rose gold system debugging and coating, can solve the problems of expensive gold targets and high processing costs, and achieve the effects of broad application prospects, reduced processing costs, good corrosion resistance and chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

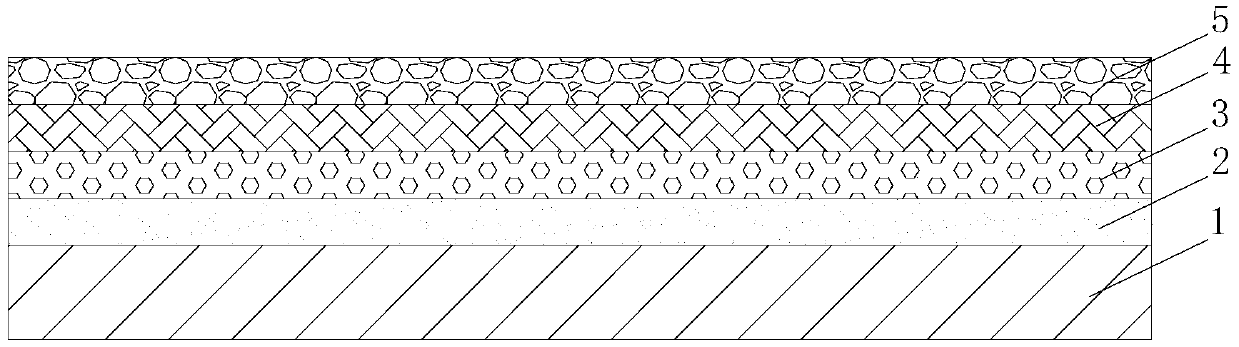

[0016] refer to figure 1 , the specific embodiment adopts the following technical scheme: a rose gold-based debugging coating technology that replaces the gold target, and the upper layer of the substrate 1 is sequentially coated with a Cr primer layer 2, a TiCrN transition layer 3, and a TiN layer by vacuum magnetron sputtering. The transition layer 4 and the TiCN color layer 5 finally make the surface appear rose gold, and the process steps are as follows:

[0017] ① Substrate 1 is made of stainless steel or hard alloy substrate. Substrate 1 undergoes CNC, polishing, and ultrasonic cleaning processes before plating Cr primer layer 2, so that the surface of the substrate is smooth and clean, which facilitates the deposition of the film layer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com