Preparation method of black rutile phase titanium dioxide

A technology of rutile phase and titanium dioxide, which is applied in the field of titanium dioxide, can solve the problems of low utilization rate of sunlight and achieve the effects of low price, low production cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

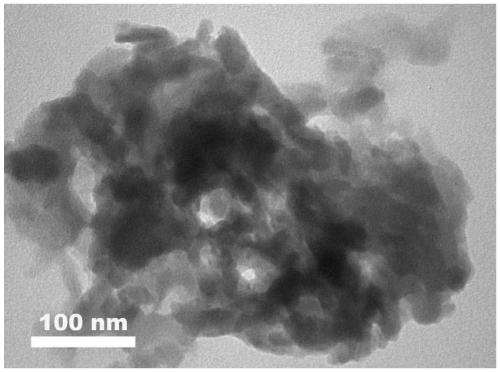

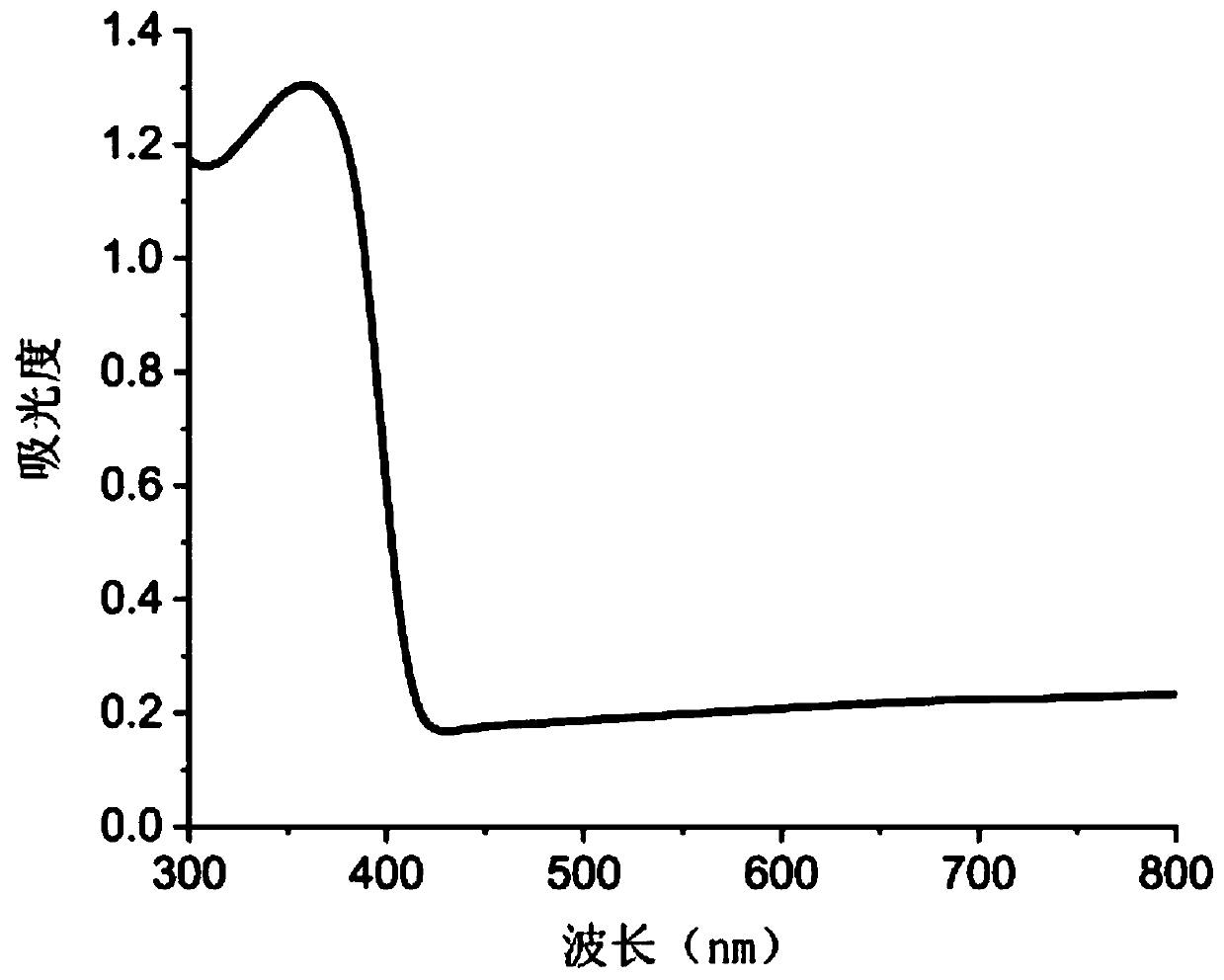

[0029] A kind of preparation method of black rutile phase titanium dioxide, comprises the steps: with 1mL TiCl 4 Dissolve in 10mL of absolute ethanol, put it in an oven at 70°C for 5 hours to completely evaporate the absolute ethanol, and obtain the precursor of amorphous titanium oxide; take the precursor of amorphous titanium oxide and put it in a corundum crucible, and place it at high temperature In the muffle furnace, heat up to 600°C at a rate of 15°C / min, heat-preserve and calcinate for 3 hours, and cool down to room temperature to obtain white rutile phase titanium dioxide; add 0.1g of white rutile phase titanium dioxide to 6M hydrochloric acid aqueous solution for ultrasonic dispersion, and then add 0.3g zinc powder, stirred for 15min, centrifuged, washed the precipitate, dried to obtain black rutile phase titanium dioxide.

[0030] Take the above-mentioned black rutile phase titanium dioxide and white rutile phase titanium dioxide for detection, the results can be fo...

Embodiment 2

[0035] A kind of preparation method of black rutile phase titanium dioxide, comprises the steps: with 2mL TiCl 4 Dissolve in 10mL of absolute ethanol, put it in an oven at 70°C for 6 hours to completely evaporate the absolute ethanol, and obtain the precursor of amorphous titanium oxide; take the precursor of amorphous titanium oxide and put it into a corundum crucible, and place it at high temperature In the muffle furnace, heat up to 700°C at a rate of 15°C / min, heat-preserve and calcinate for 3 hours, and cool down to room temperature to obtain white rutile phase titanium dioxide; add 0.2g of white rutile phase titanium dioxide to 6M hydrochloric acid aqueous solution for ultrasonic dispersion, and then add 0.4g zinc powder, stirred for 20min, centrifuged, washed the precipitate, dried to obtain black rutile phase titanium dioxide.

Embodiment 3

[0037] A kind of preparation method of black rutile phase titanium dioxide, comprises the steps: with 3mL TiCl 4 Dissolve in 10mL of isopropanol, put it in an oven at 80°C for 8 hours to completely evaporate the isopropanol, and obtain the precursor of amorphous titanium oxide; take the precursor of amorphous titanium oxide and put it into a corundum crucible, and place it at high temperature In a muffle furnace, heat up to 650°C at a rate of 5°C / min, heat-preserve and calcinate for 4 hours, and cool down to room temperature to obtain white rutile phase titanium dioxide; add 0.1g of white rutile phase titanium dioxide to 8M hydrochloric acid aqueous solution for ultrasonic dispersion, and then add 0.4g magnesium powder, stirred for 18min, centrifuged, washed the precipitate, dried to obtain black rutile phase titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com