Mass preparation method of high-performance graphene film, graphene film and antenna

A graphene film, a high-performance technology, applied in the direction of graphene, chemical instruments and methods, antennas, etc., can solve the problems of difficult mass production, high cost, high energy consumption, etc., to overcome the lack of uniformity and reduce the cost of preparation , the effect of high degree of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

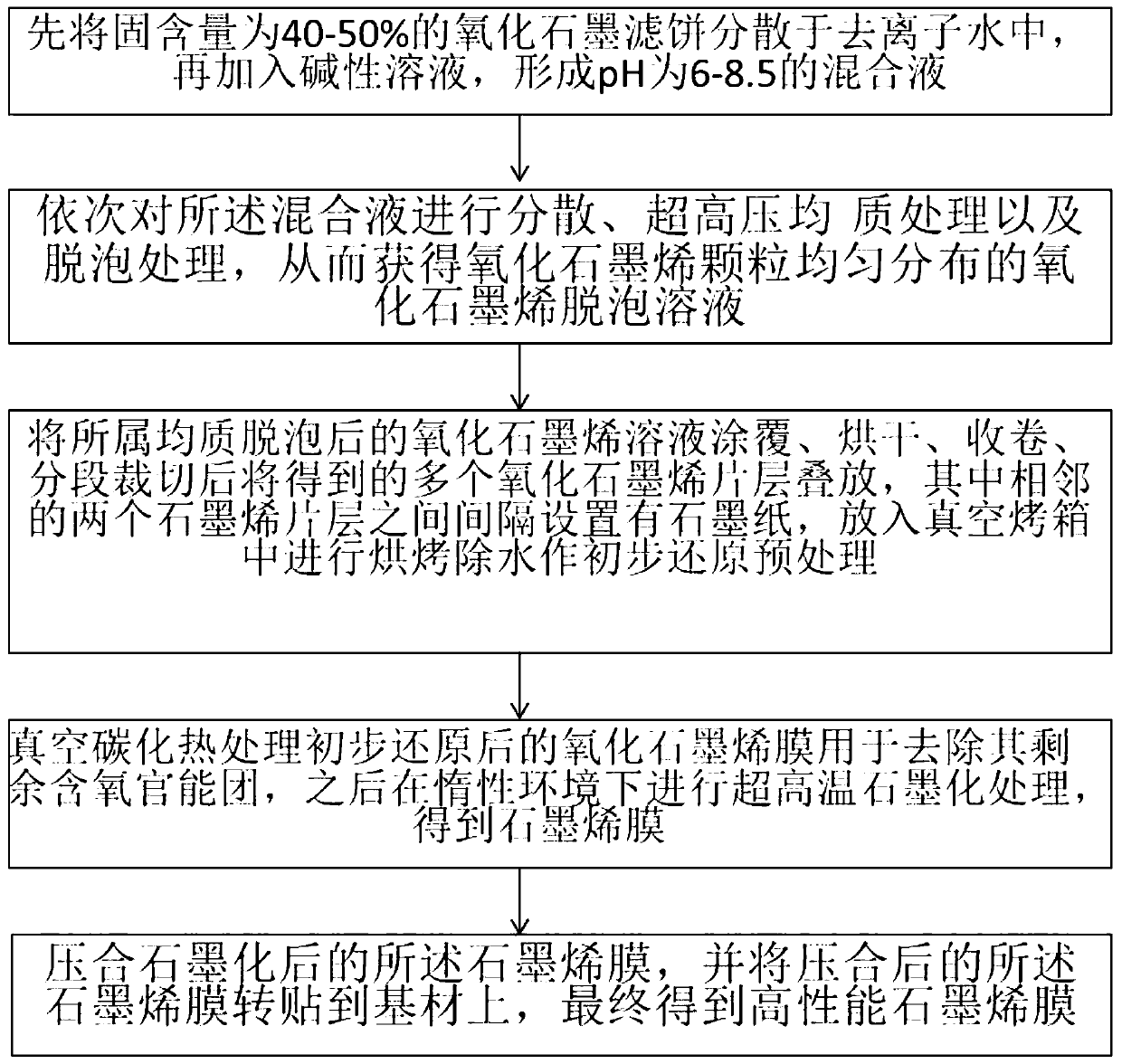

[0019] see figure 1 , this embodiment provides a batch production method of high-performance graphene film, the preparation method is used for batch production of graphene film, and includes the following steps 1 to 5.

[0020] Step 1. First disperse the graphite oxide filter cake block with a solid content of 40-50% in deionized water, and then add an alkaline solution to form a graphite oxide mixed solution with a pH of 6-8.5.

[0021] Wherein, the alkaline solution can be ammonia water, sodium hydroxide, etc., and the particle size of the graphite oxide in the graphite oxide filter cake is 80-150 μm, and the solid content of the graphite oxide in the mixed liquid is 4-7 wt%. In this embodiment, by adjusting the pH of the mixed solution, the graphite oxide solid content of the solution can be increased, and the force between graphite oxide sheets in the mixed solution can be enhanced.

[0022] Step 2, performing pre-dispersion, ultra-high pressure homogeneous treatment and ...

Embodiment 2

[0036] This embodiment provides a batch preparation method of a high-performance graphene membrane, which is further refined on the basis of Embodiment 1. In this embodiment, the pH of the mixed liquid in step 1 is adjusted to 7.2, the viscosity of the dispersed graphite oxide mixed liquid in step 2 is 400000 cps, and the solid content after dispersion is 6.4 wt%. The graphene oxide solution is obtained by performing ultrahigh pressure homogenization treatment on the graphite oxide mixed solution through an ultrahigh pressure homogenizer, and the viscosity of the treated graphene oxide solution is about 43000 cps. In step 3, the graphene oxide solution is coated on a 0.4mm porous mesh polypropylene substrate by doctor blade coating to form a 3mm thick graphene oxide solution coating layer, and then baked at a low temperature in the drying tunnel of the coating machine to obtain Graphene oxide film, the temperature distribution of the 8-section drying tunnel is 60°C, 70°C, 80°C...

Embodiment 3

[0039] This embodiment provides a high-performance graphene film, which is prepared by the batch preparation method of the high-performance graphene film in embodiment 1 or embodiment 2. The high-performance graphene film of this embodiment has better uniformity, and the flatness and physical properties have been greatly improved compared with the existing graphene film. Moreover, the cost of preparation is lower, and the efficiency and quality are higher, and it can be prepared in large quantities to achieve large-scale mass production, which can meet the actual market demand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com