High-conductivity silicon-oxygen negative electrode material and application thereof

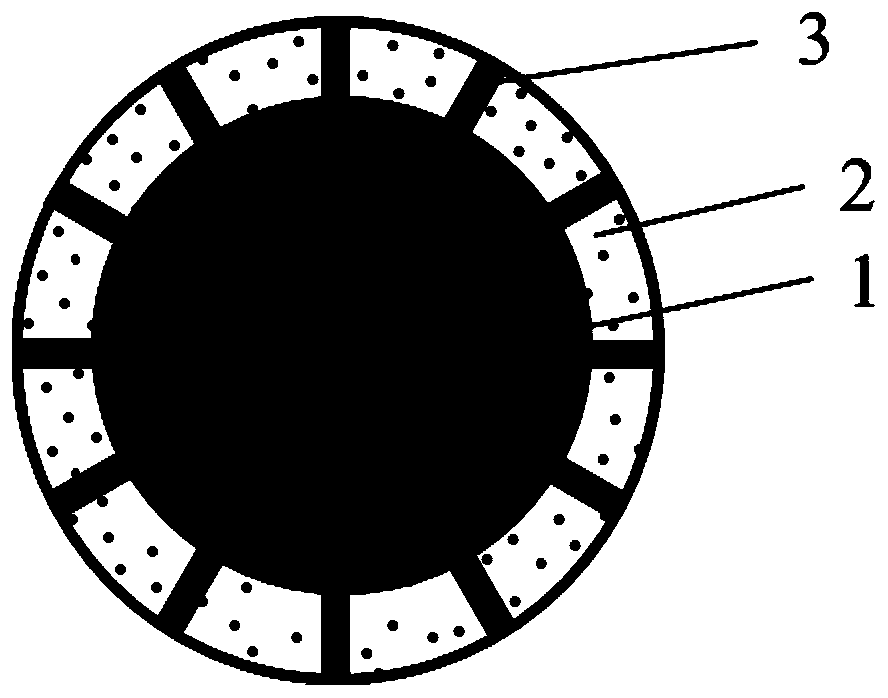

A negative electrode material and high conductivity technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor electronic conductivity, lower material performance, and difficulty in achieving results, so as to increase material capacity, increase electrical conductivity, and accelerate The effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

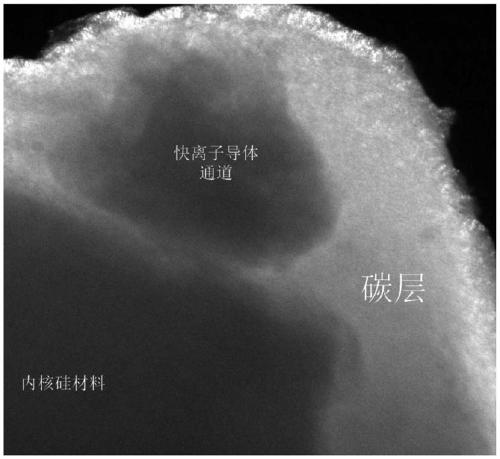

[0027] Grind lithium metaphosphate in an ethanol solvent with a sand mill until the particle size is within 50nm, then add SiO powder with a particle size of 5 μm and pitch carbon source, mix evenly, and the pitch addition ratio ensures that the final carbon content is 4% to ensure The thickness of the carbon layer is 50nm, which is spray-dried and sintered and carbonized at 900°C for 2 hours to obtain the silicon-oxygen negative electrode material. Since the thickness of the carbon layer is consistent with the particle size of lithium metaphosphate, lithium metaphosphate can form a complete channel.

[0028] The obtained sample is prepared into a button half battery, and the specific steps include: mixing the silicon-oxygen negative electrode material with CMC (sodium carboxymethyl cellulose), Super P, and SBR (styrene-butadiene rubber) in a ratio of 96.2:1.2:1:1.6 Evenly, then add deionized water to adjust into a slurry, evenly coated on the copper foil, dried, rolled, cut i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com